Hi,

Could you please help me with proper tool choice for the following task:

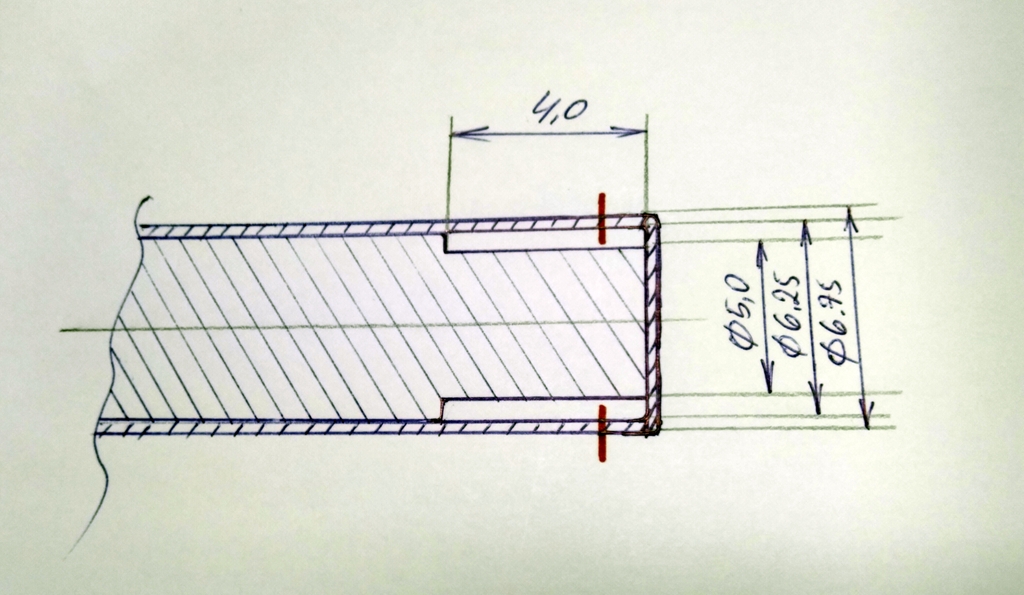

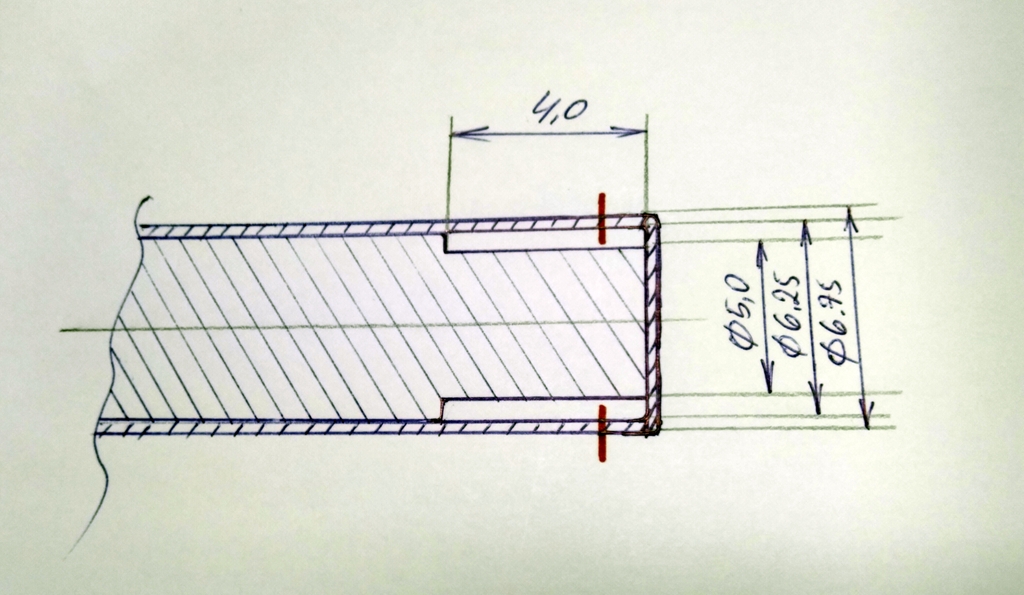

I need to cut off (red line shows where to cut) the thin stainless steel cap covering the end of the shaft.

(dimensions in millimeters)

I am beginner, zero previous experience.

Could you please help me with proper tool choice for the following task:

I need to cut off (red line shows where to cut) the thin stainless steel cap covering the end of the shaft.

(dimensions in millimeters)

I am beginner, zero previous experience.