- Joined

- Jan 2, 2019

- Messages

- 6,488

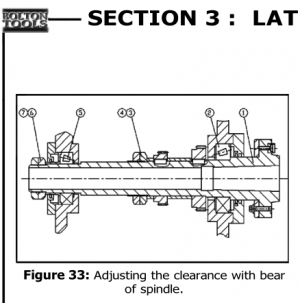

Here's the manual if anyone wants to look.

John

John

It was built in 2012, wish it was Taiwanese but this will have to do for now.I knew you'd posted a picture previously, but I was have difficulty finding it. (operator error, blaming it on the heat.)

Found it -=- Here -=-

Looks so similar to my Taiwan 1440 Birmingham. Do the tags note what year was this one was made in?

I prefer the style of the Power Lever and the way it is 'Doglegged' compared to how the Birmingham is, I may ask you for some detailed pictures in the future.

Do you have a paper or electronic copy of the manual?

Thank you Dan, for posting a link to Bolton.

I guess this lathe is a equivalent to the 13 x 37 shown on the Bolton site.

I looked at the specs and the Manual, available on-line, and found no mention of the spindle nose configuration. CRAZY!

John,

Have you contacted Bolton about a replacement Gap piece?

Have a look and tell me what you think....

Have a look and tell me what you think....