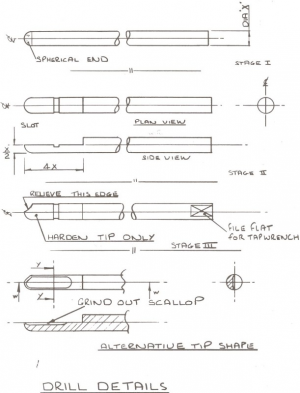

In stating that the groove would make it stiffer I mean that it would be stiffer in comparison to just milling a flat across the end of the bit which is what most shop made ones are like. I would imagine it would add some stiffness where the cutting takes place and would have tendency to guide it more accurately as well. More material can't make it less rigid. There must be a reason that guns drills are made that way. This is only a guess on my part. But it couldn't make it worse at any rate.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D Bit Confusion

- Thread starter Allan

- Start date

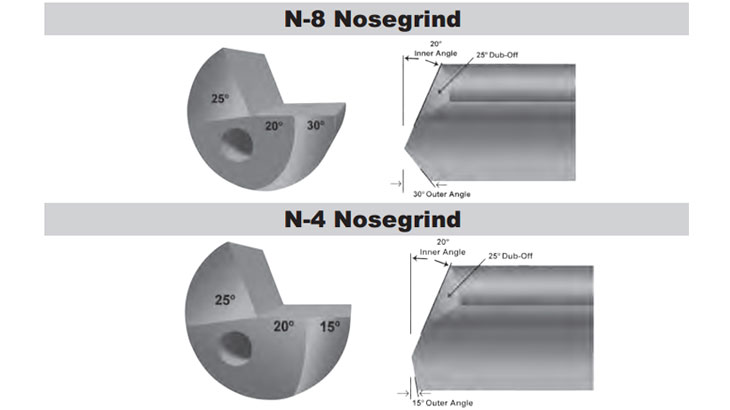

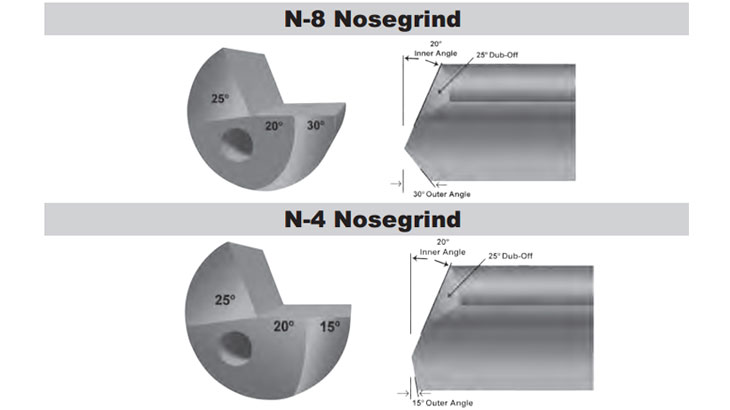

Here is a link to a commercial site showing their gun drill geometry:

m4sciences.com

m4sciences.com

5 Gun Drill Mistakes You May Be Making

Find out what gun drill mistakes you could be making and what the effects are on your parts manufacturing.

m4sciences.com

m4sciences.com

- Joined

- Jan 31, 2016

- Messages

- 11,422

I do route #1 with mine. It is a good design for chasing holes because it reams as it drills, giving you a very straight result.

Is this what ou consider a dreamer ? I have a lot of these down the basement . Drills and reamers combined .

- Joined

- Dec 9, 2016

- Messages

- 1,133

In stating that the groove would make it stiffer I mean that it would be stiffer in comparison to just milling a flat across the end of the bit which is what most shop made ones are like. I would imagine it would add some stiffness where the cutting takes place and would have tendency to guide it more accurately as well. More material can't make it less rigid. There must be a reason that guns drills are made that way. This is only a guess on my part. But it couldn't make it worse at any rate.

I guess I just Dont Understand what it is you are trying to describe, Not the first time thats happed to me!!! Thanks for posting that link......

I actually quickly read through that site before you posted it but I fail to see any information that supports your theory, oh well, not a big deal for me at the moment but will definitely look more into this before I proceed down that path.

Thanks anyway.

- Joined

- Apr 23, 2018

- Messages

- 6,508

Here is an example.Is this what ou consider a dreamer ? I have a lot of these down the basement . Drills and reamers combined .

pontiac, that looks nice. I guess you could call it that. As in most things of old people call them by different names. My understanding is that there are D Drills and then there are D Reamers. The former is for making a hole where there was not one before and the latter is for enlarging an existing hole. There seems to be lots of overlap in terms and uses. "Dreamer". I like that.

Can you fill us in on angles and tell us how well it works?

Can you fill us in on angles and tell us how well it works?

- Joined

- Apr 23, 2018

- Messages

- 6,508

Yes, it's centered. This one was meant to work as a countersink, but it drills too. I wouldn't change the tip location, but for a dedicated drill I would add 5 degrees of back relief and grind it further up the shank for better chip exits.

Edit: The point can be any angle. The back cut can be 0 or 5 degrees, but I haven't tested enough to say one is better. The facet covers 15 degrees because that's the step my indexing workhead is divided in.

Edit: The point can be any angle. The back cut can be 0 or 5 degrees, but I haven't tested enough to say one is better. The facet covers 15 degrees because that's the step my indexing workhead is divided in.

- Joined

- Dec 9, 2016

- Messages

- 1,133

Ahh i think I see where the confusion is coming into play! You seem to be speaking of the cutting portion of the bit itself where I thought you where speaking of the "single flute" yhat runs the entire length of some of that style drill bit.Well if you mill half of a bit away it will not be as rigid as only milling 1/4 of it away. Lets see if this posts: