I have a the typical Chinese TCG purchased from Accusize here in Canada a few years back. Sadly not getting the attention it deserves, but I aim to change that.

accusizetools.com

accusizetools.com

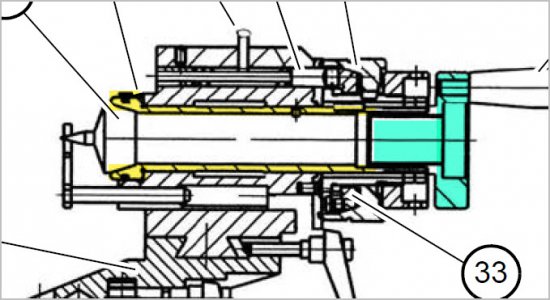

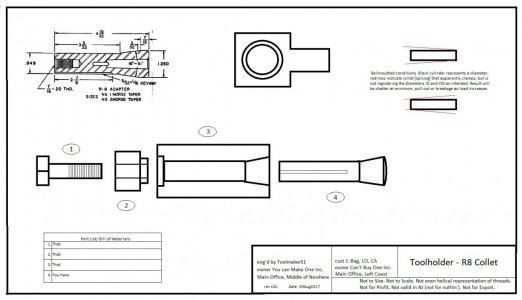

But having buyers remorse. Its R8 collet work head. At the time that was desireable because most were the Ux Dekel format which were pita to source. I already have a full set of good quality 5C collets, limited selection of R8. I could go out & buy R8 set but having tough time justifying. I don't really use them all that often in the mill or other applications. Maybe it was around the same time but Shars offered their 5C model.

www.shars.com

www.shars.com

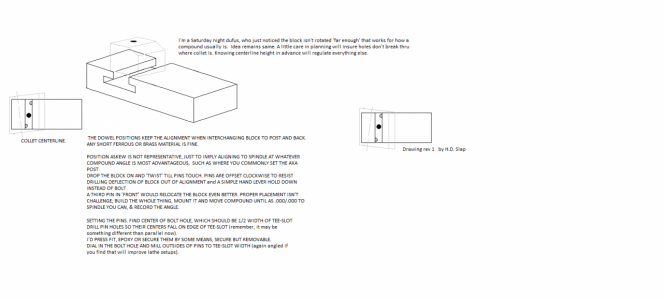

I inquired with Shars if I could buy the 5C work head separately. Thinking (hoping) it will likely fit my dovetail, since these machines look generically similar & come in R8, 5C & original Ux flavors. The answer is yes, comes with the pivot for some reason. Not cheap, but maybe inline with collet set.

www.shars.com

www.shars.com

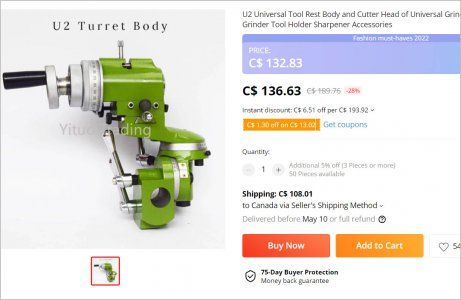

Then I went lurking on AliExpress & Ebay. Rather confusing & still waiting on some replies but possibly I can get 5C head via that avenue, example pic

My question is, have any of you swapped out a head? Any issues I should be aware of? Shars mentioned one of the flute attachment guide accessories wont fit the same, of no real consequence.

2301-1007, MY-30A Universal Cutter Grinder with Standard Accessories, 110v, 60hz

When you choose Universal End Mill Cutter Drill Bit Grinder Sharpener, it works as the following tools (and solutions): Universal End Mill Cutter Drill Bit Grinder Sharpener, etc.

But having buyers remorse. Its R8 collet work head. At the time that was desireable because most were the Ux Dekel format which were pita to source. I already have a full set of good quality 5C collets, limited selection of R8. I could go out & buy R8 set but having tough time justifying. I don't really use them all that often in the mill or other applications. Maybe it was around the same time but Shars offered their 5C model.

Universal End Mill Cutter Drill Bit Grinder Sharpener

I inquired with Shars if I could buy the 5C work head separately. Thinking (hoping) it will likely fit my dovetail, since these machines look generically similar & come in R8, 5C & original Ux flavors. The answer is yes, comes with the pivot for some reason. Not cheap, but maybe inline with collet set.

End Mill Sharpening Attachment

Then I went lurking on AliExpress & Ebay. Rather confusing & still waiting on some replies but possibly I can get 5C head via that avenue, example pic

My question is, have any of you swapped out a head? Any issues I should be aware of? Shars mentioned one of the flute attachment guide accessories wont fit the same, of no real consequence.