I've been watching a lot of TCG YouTube content & its amazing the variation in usage. I guess on one hand that possibly speaks to the flexibility of the D-bit style machine. Or maybe another perspective is that not all methods are awesome.

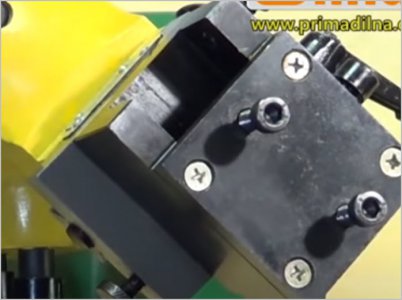

The Vee drill holder accessory included with my kit is not pretty from any angle. I've seen some people toss it aside, others modify, others rebuild from scratch using better drill retention & orientation clamps. As best I can figure this jig is meant to grind the classic edge where the cone relieves back continuously via the jig swiveling on its axle in the collet. But I think it could also rock laterally across the ways of desired? So that Vee jig would accommodate variable drill diameters & therefore not confined to matching collets. Stefan shows a drill held in collet with the 4-facet method stroking across the wheel (only) no rotational component other than to repeat operation at 180-deg. So this would require matching collets.

Toolmaker51 I've looked around for R8 collet blocks in the past. They are not abundant the way 5C & R8 are. They could be made. the bigger question is then what? I could maybe remove the collet work head & mount to a different/dedicated tooling block like the one they offer for lathe tools & what not. The good thing is the dovetails would lend themselves to tool block retention. Not sure how that would help hold incremental dill sizing. I was thinking something like a precision mini chuck. But that might have the same sickout issues as ER & be even more limited to length.

I'm sure there is a solution in here somewhere & once I get going on it things will become more apparent. The decision meter is still tilting slightly to 5C though.

I'm also getting a vibe that there are different quality builds to these not necessarily reflected in pictures. The U2 style Stefan.G has & the Shars U2 that Rob Renzetti has looks better than mine in may regards. And I'm not talking about their replaced parts & overclocking features. The Shars has nice rotation shafts for the work heads, mine are meaty chunks of blacksmith iron. Rob.R mentioned the Grizzly (Taiwan?) is an upscale version of his (Chinese) but 2-3x the cost. I assumed all Chinese TCG's were probably the same, but I now have my doubts.

Before I go too far, I did some searching on forum but surprisingly there isn't really a lot of posts & chatter on these TCG's which surprised me. Am I missing some forum areas where these are discussed in more detail? Happy to start something & can post the YouTube links etc. I've collected. Would be happy to hear how others are getting on with theirs.

The Vee drill holder accessory included with my kit is not pretty from any angle. I've seen some people toss it aside, others modify, others rebuild from scratch using better drill retention & orientation clamps. As best I can figure this jig is meant to grind the classic edge where the cone relieves back continuously via the jig swiveling on its axle in the collet. But I think it could also rock laterally across the ways of desired? So that Vee jig would accommodate variable drill diameters & therefore not confined to matching collets. Stefan shows a drill held in collet with the 4-facet method stroking across the wheel (only) no rotational component other than to repeat operation at 180-deg. So this would require matching collets.

Toolmaker51 I've looked around for R8 collet blocks in the past. They are not abundant the way 5C & R8 are. They could be made. the bigger question is then what? I could maybe remove the collet work head & mount to a different/dedicated tooling block like the one they offer for lathe tools & what not. The good thing is the dovetails would lend themselves to tool block retention. Not sure how that would help hold incremental dill sizing. I was thinking something like a precision mini chuck. But that might have the same sickout issues as ER & be even more limited to length.

I'm sure there is a solution in here somewhere & once I get going on it things will become more apparent. The decision meter is still tilting slightly to 5C though.

I'm also getting a vibe that there are different quality builds to these not necessarily reflected in pictures. The U2 style Stefan.G has & the Shars U2 that Rob Renzetti has looks better than mine in may regards. And I'm not talking about their replaced parts & overclocking features. The Shars has nice rotation shafts for the work heads, mine are meaty chunks of blacksmith iron. Rob.R mentioned the Grizzly (Taiwan?) is an upscale version of his (Chinese) but 2-3x the cost. I assumed all Chinese TCG's were probably the same, but I now have my doubts.

Before I go too far, I did some searching on forum but surprisingly there isn't really a lot of posts & chatter on these TCG's which surprised me. Am I missing some forum areas where these are discussed in more detail? Happy to start something & can post the YouTube links etc. I've collected. Would be happy to hear how others are getting on with theirs.

Attachments

Last edited: