Hi all,

First post on the forum!

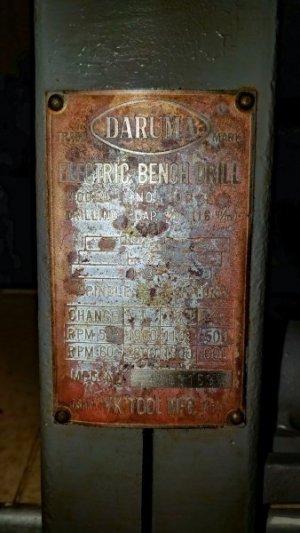

We're talking about an old Daruma drill press. The model mentioned in the title.

I can't find any information about it, probably because it's from the pre-internet knowledge sharing times.

The only place I see this drill press on the web is on graysonline auctions, so I assumed that this DP was/is sold mostly in Australia.

This is a DP that I'm restoring or refreshing or what have you.

My question is if anyone here knows of a store/website that sells spare parts for this DP.

While trying to get the bearings off the spindle, I wacked it too hard and bent it a bit. I'm afraid to even check the runout. I'm hoping to be able to find a new or used spindle.

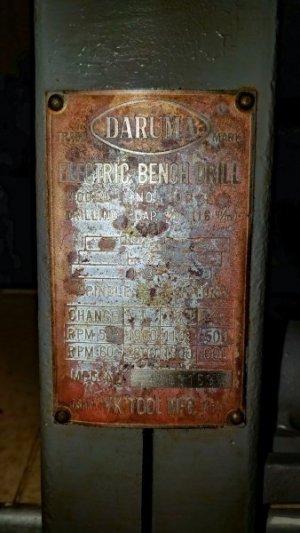

Other than that, I also can't figure out what the taper is on the spindle (see attached photo). It needs a new Chuck.

Thank you in advance guys/gals!

First post on the forum!

We're talking about an old Daruma drill press. The model mentioned in the title.

I can't find any information about it, probably because it's from the pre-internet knowledge sharing times.

The only place I see this drill press on the web is on graysonline auctions, so I assumed that this DP was/is sold mostly in Australia.

This is a DP that I'm restoring or refreshing or what have you.

My question is if anyone here knows of a store/website that sells spare parts for this DP.

While trying to get the bearings off the spindle, I wacked it too hard and bent it a bit. I'm afraid to even check the runout. I'm hoping to be able to find a new or used spindle.

Other than that, I also can't figure out what the taper is on the spindle (see attached photo). It needs a new Chuck.

Thank you in advance guys/gals!