After falling down the mini lathe rabbit hole I discovered yet another one when the enablers on this site ganged up on me. After being amazed by how well the tool worked that @ttabbal ground and sent to me I set out to be able to grind my own. Then came a 1000 PM's back and forth with @mikey on what I needed for a sander and exactly how to go about the actual grinding. Once I got @mikey 's models from @Z2V I wanted to get a grinder set up correctly ASAP. So thanks to @mikey , @ttabbal and @Z2V for throwing me over this cliff.

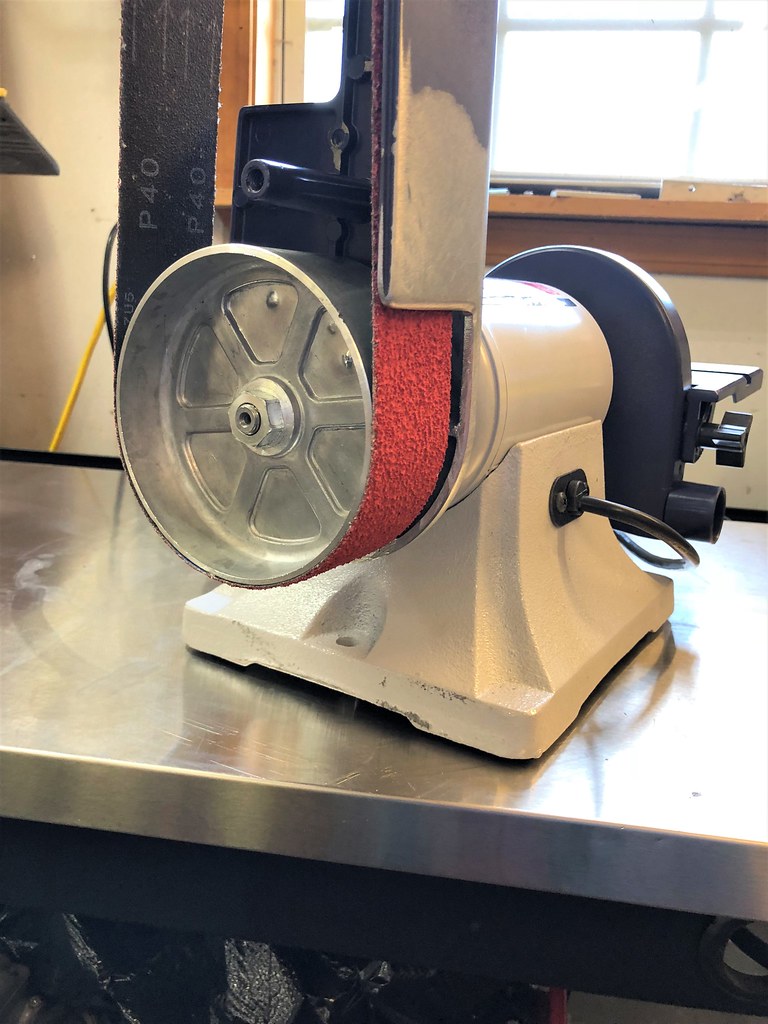

I'm a total machining newbie. Definitely just a hobby for me but I like to have the right tools for whatever I'm doing. I simply could not justify spending $500+ on a nice sander nor did I want to invest the time to build one from scratch so I started researching one that I could afford. Enter the Dayton 6Y945 2x42/disc sander. It's available from multiple suppliers but I opted to get mine at Grainger. They had a good price ($149.50) and my local store is 2 minutes from my work.

Dayton 6Y945 @ Grainger

The modifications that will be made are to make a solid platen base and add a 01 tool steel platen backer and a Pyroceram platen per @mikey 's mods to his sander. I'm also making a new table from 1/4 steel plate including a more stable mounting and more repeatable adjust-ability.

Link to that article..

http://www.machinistblog.com/modifying-a-craftsman-2-x-42-inch-belt-sander-for-tool-grinding/

I sourced the backer and the plate on Ebay. Here are those links.

$21.18 shipped. 01 tool steel backer...

https://www.ebay.com/itm/O1-Tool-St...e=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

$21.00 shipped. Pyroceram platen...

https://www.ebay.com/itm/Glass-plat...m=163066307996&_trksid=p2047675.c100011.m1850

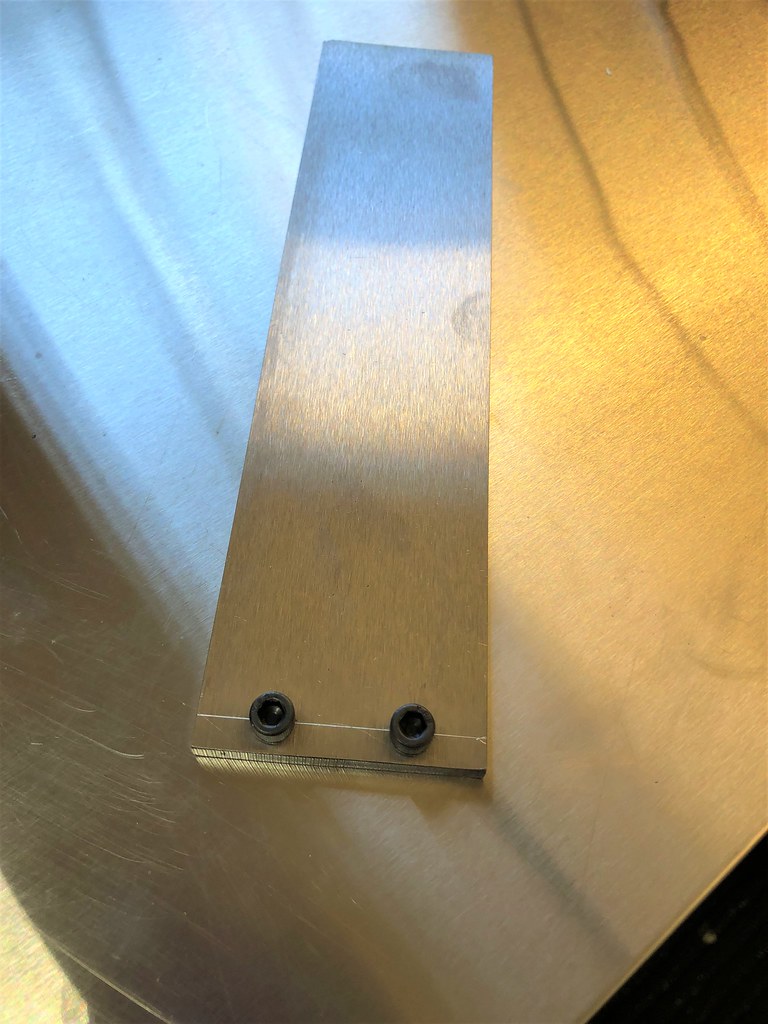

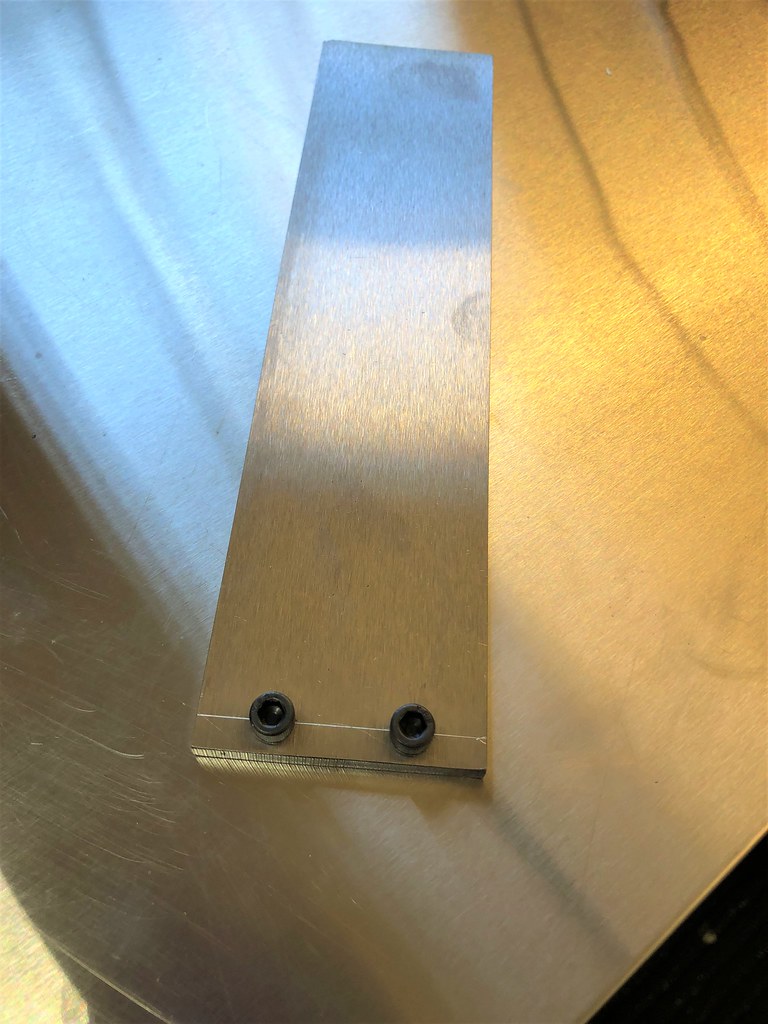

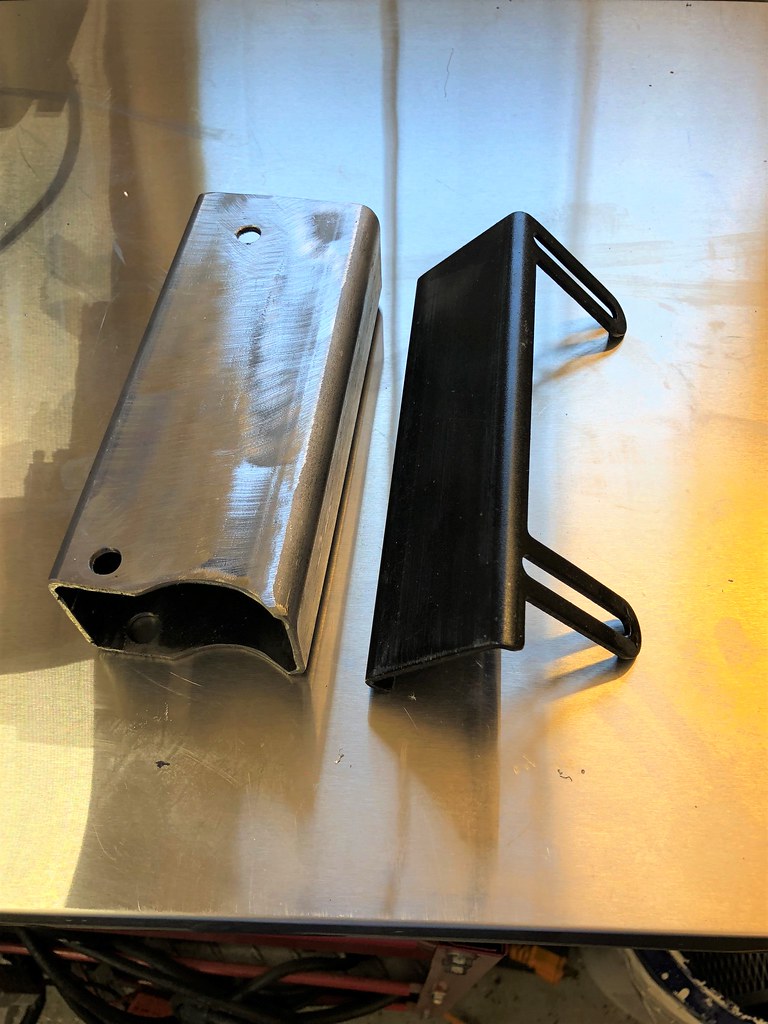

Here's the backer and the platen.

The glass will be attached to the backer with JB Weld. For added safety I drilled and tapped for 2 10-24 cap screws for the platen to rest on.

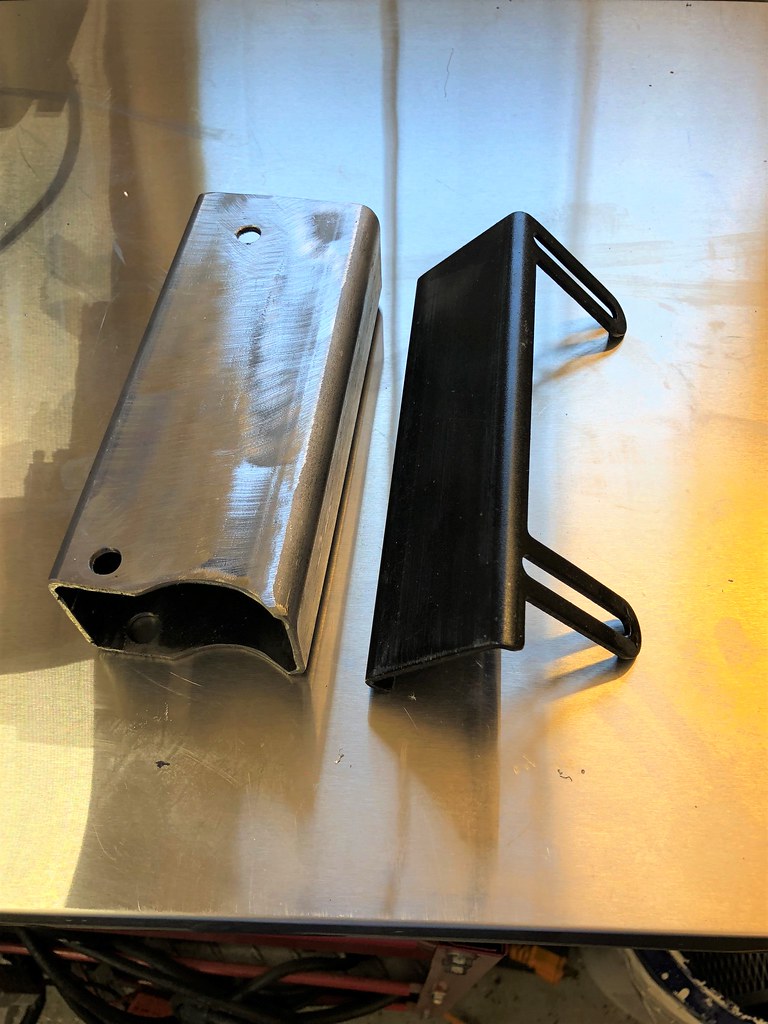

The original platen flexes and that is not what we need for this application. The new one is made from 2x3x.125 rectangular tubing. Definitely not going to flex.

I drilled holes to match the original to mount it to the sander and to mount the platen backer. The backer was drilled and tapped for 2 1/4-20 cap screws. I drilled oversize holes in the back and side to access those cap screws. I also radiused the bottom edge to clear the upcoming new table mounts.

New vs original.

And with the platen backer mounted.

Once that assembly is complete I attached the platen to the backer. Regular JB Weld and some light clamping pressure do the job. I sanded the back of the platen with 80 grit paper to give it some tooth.

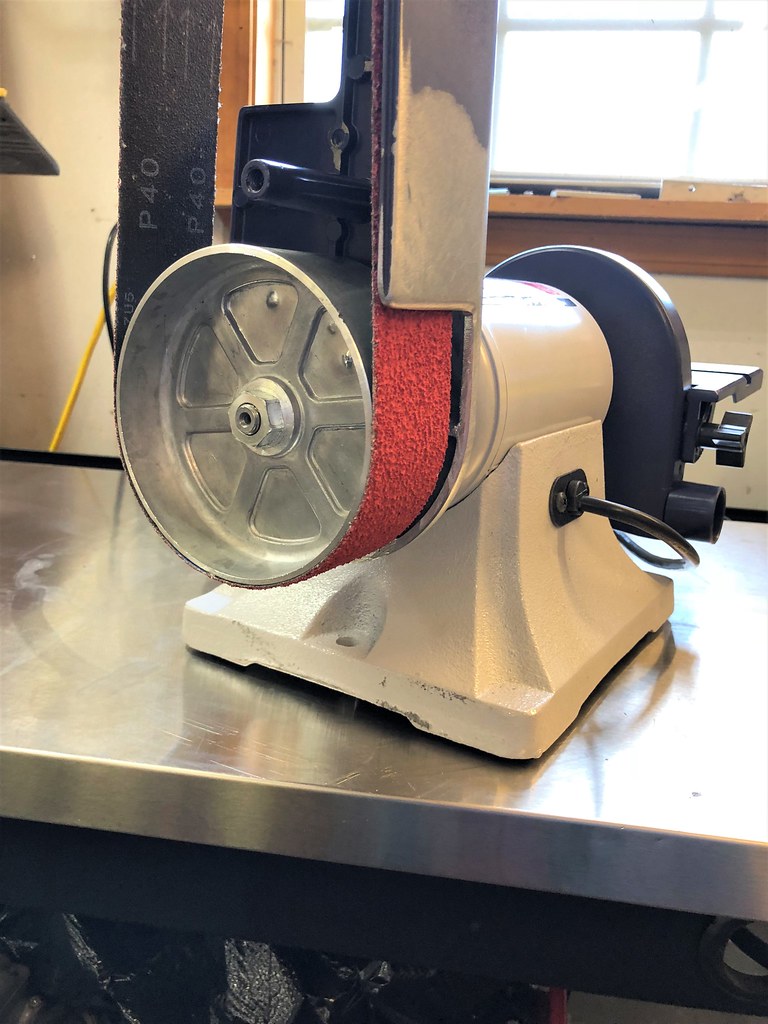

While the glue up cures, I need to solve an interesting problem with the sander. My best guess is that the folks at Dayton were determined to not allow super coarse paper to be used on the machine as it's only 1/3 hp. Per @mikey 's suggestion, I have 40 grit ceramic paper and it literally will not fit between the drive wheel and the housing. I had to cut the lower portion of the housing off to allow clearance for the belt.

The new table will be mounted on a piece of 10mm all thread vs just the single bolt as it has brackets on both sides instead of just one side like the original so I went ahead and mounted the all thread even though I'm still using the original table for now while I'm waiting on my buddy with the water jet to cut the new table parts.

The relief radius on the bottom edge allows clearance for a jam nut on the all thread.

Couple coats of Trim Black spray paint and the platen assembly is ready to mount...

I notched the belt housing cover to clear the right side table mount.

View of the new mount for the right side of the table.

With the stock table mounted and set at 15 degrees...

Now it's the moment of truth. The functionality test with 40 grit ceramic paper. I used @mikey 's instructions and the models to grind a square turning tool example on some 3/8x3/8 key stock. I was impressed with the performance of the sander. The original table is a bit of a pain as the groves are not conducive to grinding something this small but the new table should solve that.

My attempt vs the model. Lots of practice before I have this figured out but I definitely have a tool that is capable now...

For under $200 and a few hours work I am super happy with the result. Hope this helps someone that might want to mod their own!

I'm a total machining newbie. Definitely just a hobby for me but I like to have the right tools for whatever I'm doing. I simply could not justify spending $500+ on a nice sander nor did I want to invest the time to build one from scratch so I started researching one that I could afford. Enter the Dayton 6Y945 2x42/disc sander. It's available from multiple suppliers but I opted to get mine at Grainger. They had a good price ($149.50) and my local store is 2 minutes from my work.

Dayton 6Y945 @ Grainger

The modifications that will be made are to make a solid platen base and add a 01 tool steel platen backer and a Pyroceram platen per @mikey 's mods to his sander. I'm also making a new table from 1/4 steel plate including a more stable mounting and more repeatable adjust-ability.

Link to that article..

http://www.machinistblog.com/modifying-a-craftsman-2-x-42-inch-belt-sander-for-tool-grinding/

I sourced the backer and the plate on Ebay. Here are those links.

$21.18 shipped. 01 tool steel backer...

https://www.ebay.com/itm/O1-Tool-St...e=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

$21.00 shipped. Pyroceram platen...

https://www.ebay.com/itm/Glass-plat...m=163066307996&_trksid=p2047675.c100011.m1850

Here's the backer and the platen.

The glass will be attached to the backer with JB Weld. For added safety I drilled and tapped for 2 10-24 cap screws for the platen to rest on.

The original platen flexes and that is not what we need for this application. The new one is made from 2x3x.125 rectangular tubing. Definitely not going to flex.

I drilled holes to match the original to mount it to the sander and to mount the platen backer. The backer was drilled and tapped for 2 1/4-20 cap screws. I drilled oversize holes in the back and side to access those cap screws. I also radiused the bottom edge to clear the upcoming new table mounts.

New vs original.

And with the platen backer mounted.

Once that assembly is complete I attached the platen to the backer. Regular JB Weld and some light clamping pressure do the job. I sanded the back of the platen with 80 grit paper to give it some tooth.

While the glue up cures, I need to solve an interesting problem with the sander. My best guess is that the folks at Dayton were determined to not allow super coarse paper to be used on the machine as it's only 1/3 hp. Per @mikey 's suggestion, I have 40 grit ceramic paper and it literally will not fit between the drive wheel and the housing. I had to cut the lower portion of the housing off to allow clearance for the belt.

The new table will be mounted on a piece of 10mm all thread vs just the single bolt as it has brackets on both sides instead of just one side like the original so I went ahead and mounted the all thread even though I'm still using the original table for now while I'm waiting on my buddy with the water jet to cut the new table parts.

The relief radius on the bottom edge allows clearance for a jam nut on the all thread.

Couple coats of Trim Black spray paint and the platen assembly is ready to mount...

I notched the belt housing cover to clear the right side table mount.

View of the new mount for the right side of the table.

With the stock table mounted and set at 15 degrees...

Now it's the moment of truth. The functionality test with 40 grit ceramic paper. I used @mikey 's instructions and the models to grind a square turning tool example on some 3/8x3/8 key stock. I was impressed with the performance of the sander. The original table is a bit of a pain as the groves are not conducive to grinding something this small but the new table should solve that.

My attempt vs the model. Lots of practice before I have this figured out but I definitely have a tool that is capable now...

For under $200 and a few hours work I am super happy with the result. Hope this helps someone that might want to mod their own!