Hello all,

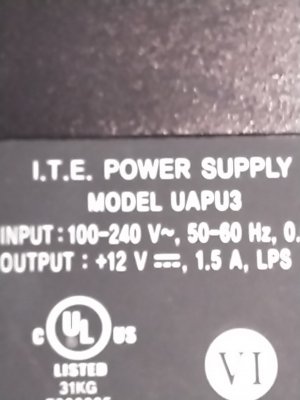

I'm in need of some advice. I'm wondering if this motor https://www.ebay.com/itm/GW370-DC12...-Motor-1-250RPM/312823496892?var=611544362472 can be run with this PWM https://www.ebay.com/itm/0-100-Digi...2V-24V-36V-48V-Reversible-40A-US/124342951962 and powered by a 19volt laptop power supply.

I've checked the load I plan to drive with a torque wrench and get 5-8 kg cm It won't be used daily but when it is it will run for several hours. any other options would be greatly appricated

I need variable speed and reversing

Thanks

I'm in need of some advice. I'm wondering if this motor https://www.ebay.com/itm/GW370-DC12...-Motor-1-250RPM/312823496892?var=611544362472 can be run with this PWM https://www.ebay.com/itm/0-100-Digi...2V-24V-36V-48V-Reversible-40A-US/124342951962 and powered by a 19volt laptop power supply.

I've checked the load I plan to drive with a torque wrench and get 5-8 kg cm It won't be used daily but when it is it will run for several hours. any other options would be greatly appricated

I need variable speed and reversing

Thanks