Not sure if this is the best way to get back to my DC motor situations but ...

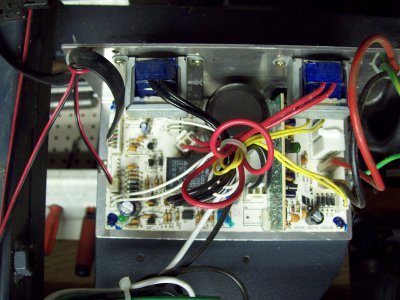

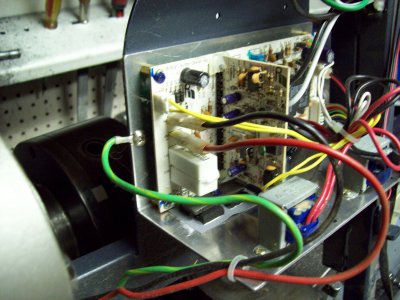

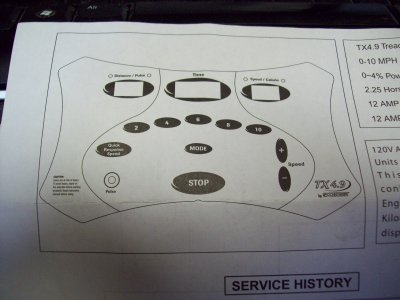

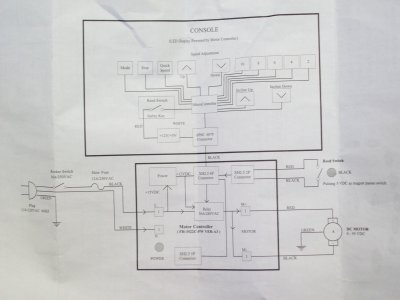

So I've gotten another treadmill motor this time with the electronic panel that controls the motor. Also have the control wire that formerly went to the operator panel but no operator panel. 6 colored wires and a green wire(total 7) are in a connector that looks similar to a phone connector. How does one determine the function of those wires so that a manual pot (possibly) or momentary buttons could be connected for speed control. Other functions on the picture of the operator panel seems to show several presets for speed, distance traveled ,time elapsed, and speed with a stop and + and - speed control. Any help even getting a direction to look would be appreciated.

So I've gotten another treadmill motor this time with the electronic panel that controls the motor. Also have the control wire that formerly went to the operator panel but no operator panel. 6 colored wires and a green wire(total 7) are in a connector that looks similar to a phone connector. How does one determine the function of those wires so that a manual pot (possibly) or momentary buttons could be connected for speed control. Other functions on the picture of the operator panel seems to show several presets for speed, distance traveled ,time elapsed, and speed with a stop and + and - speed control. Any help even getting a direction to look would be appreciated.