- Joined

- Dec 26, 2015

- Messages

- 2,079

As for centering a chuck on the RT, you might (or might not) find this video helpful or inspiring.

Last edited:

As for centering a chuck on the RT, you might (or might not) find this video helpful or inspiring.

Woops. Try this:I'm not seeing a video.

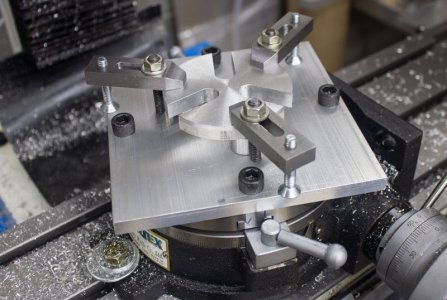

One of the ways when i did something like what you did while on the lathe I spotted with a small center drill .At the mill I have a ground center that I put in a collet brought it down slowly and moved until centered on the table , then clamped the quill and put the clamps on . Close enough for most of the jobs I do .