I just purchased an FP1 on an on-line auction. I did it sight unseen. I promised myself a few yrs ago that I would never do that again, but these things are rare as hen's teeth and it is not that far away and well, I'm, weak what can I say.

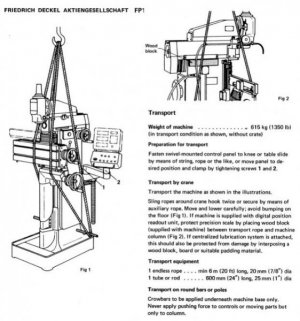

Can anyone tell me the best way to sling one of these? I was thinking wrapping a strap around the horizontal ram at the top, but that would put the whole weight of the machine on the dovetail. That seems like a bad idea. What is the proper way to lift one? Perhaps there is something in the manual, which I don't have. Anyone know of an on-line source for the manual (free)? Also, what does it weigh?

thanks

Can anyone tell me the best way to sling one of these? I was thinking wrapping a strap around the horizontal ram at the top, but that would put the whole weight of the machine on the dovetail. That seems like a bad idea. What is the proper way to lift one? Perhaps there is something in the manual, which I don't have. Anyone know of an on-line source for the manual (free)? Also, what does it weigh?

thanks