-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

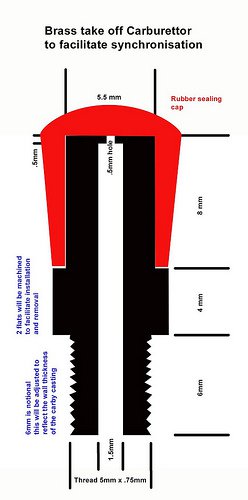

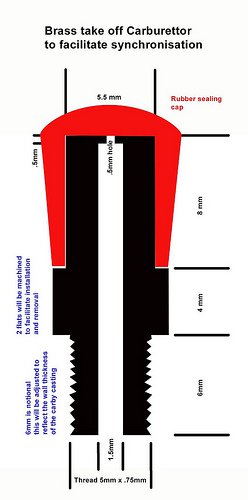

Design For Machining Vacuum Take Off Point For Old Style Carbs

- Thread starter malmac

- Start date

- Joined

- Jan 20, 2016

- Messages

- 1,011

Not sure what you are balancing but this trick might work.

I've had a couple XKE Jags with triple SU carbs. Years and years ago an old master Jag mechanic showed me an easy way to balance the carbs. Take a piece of plastic tubing. A a 2 foot section of garden hose will work. Any old hose or tube will work. With the motor at an idle hold the tube at the mouth of one of the carbs and hold the other end to your ear. Listen to the sound. Move the tubing to another carb and hold the hose in the same relative spot as the first. Adjust the carb until it sounds like the first carb. Repeat for the third carb. It works!!

I know this method sounds inaccurate but it is not. Later in life, working as a motorcycle mechanic I would use the hose method to sync all 4 carbs on Gold Wings. Then I would check the balance with a manometer. The hose method was always spot on. It is amazing how much difference in sound a 1/16 of a turn on the screw will make.

I've had a couple XKE Jags with triple SU carbs. Years and years ago an old master Jag mechanic showed me an easy way to balance the carbs. Take a piece of plastic tubing. A a 2 foot section of garden hose will work. Any old hose or tube will work. With the motor at an idle hold the tube at the mouth of one of the carbs and hold the other end to your ear. Listen to the sound. Move the tubing to another carb and hold the hose in the same relative spot as the first. Adjust the carb until it sounds like the first carb. Repeat for the third carb. It works!!

I know this method sounds inaccurate but it is not. Later in life, working as a motorcycle mechanic I would use the hose method to sync all 4 carbs on Gold Wings. Then I would check the balance with a manometer. The hose method was always spot on. It is amazing how much difference in sound a 1/16 of a turn on the screw will make.

- Joined

- Nov 26, 2012

- Messages

- 1,307

I to have learned to use a hose as groundhog says. Back in the 90's Arctic cat had the special carb sinc tool from suzuki. All dealers got one as part of the required special tool package.

I remember the service guys at arctic cat telling of a suzuki factory tech from japan using a hose to balance the carbs instead of the expensive "special tool" they were selling us.

He just used a length of 5/16 fuel line. One end in carb mouth and one end in ear. Works great just like groundhog says.

I remember the service guys at arctic cat telling of a suzuki factory tech from japan using a hose to balance the carbs instead of the expensive "special tool" they were selling us.

He just used a length of 5/16 fuel line. One end in carb mouth and one end in ear. Works great just like groundhog says.

- Joined

- Jun 7, 2016

- Messages

- 361

Russ

I could easily put a small screw in the end - the gauges I have come with some extension pipes (for the inner cylinders on 4 cylinder engines I am guessing). These pipes have one end blocked off and a very small hole drilled in the centre. Do you know why the hole has to be so small? If I put a screw in the end the hole is going to be quite a lot larger - depending on why the hole is so small, I could move the narrow section down further into the body of the fitting.

Mal

I could easily put a small screw in the end - the gauges I have come with some extension pipes (for the inner cylinders on 4 cylinder engines I am guessing). These pipes have one end blocked off and a very small hole drilled in the centre. Do you know why the hole has to be so small? If I put a screw in the end the hole is going to be quite a lot larger - depending on why the hole is so small, I could move the narrow section down further into the body of the fitting.

Mal

- Joined

- Nov 26, 2012

- Messages

- 1,307

You sent me looking for my suzuki carb balancer. Didn't find it guess I sold it on ebay years ago.

Remembering a few things though. The suzuki one had brass end pieces that were threaded and the mikuni carb on the snowmobile had a philips screw in the throat of the carb on the engine side of the slide. There was no nipple protuding from the carb just a threaded hole with a screw.

If working on a motorcycle with protuding nipples the brass end pieces were removed and the hose pushed on the nipple.

If I remember right (questionable) I think some of the hondas had a protuding nipple with a very small screw plugging the end of them instead of a rubber cap.

The hole size I don't believe makes any difference. It just needs to be consistant for all lines/carbs. Different engines and different line/fitting sizes are going to effect the setting, but the balancer needs reset every time used anyway. Tipicaly one would get the engine running consitantly and then adjust the ballancer by hooking one hose up at a time and adjusting the ball leavel this way all 4 are adjusted the same since they all show the same leavel when hooked up to the same carb one after the other. Then they can all be hooked to a cylinder and the difference in carb balance viewed and adjusted.

I hope we are talking about the floating ball type balancer. that's what I had.

Remembering a few things though. The suzuki one had brass end pieces that were threaded and the mikuni carb on the snowmobile had a philips screw in the throat of the carb on the engine side of the slide. There was no nipple protuding from the carb just a threaded hole with a screw.

If working on a motorcycle with protuding nipples the brass end pieces were removed and the hose pushed on the nipple.

If I remember right (questionable) I think some of the hondas had a protuding nipple with a very small screw plugging the end of them instead of a rubber cap.

The hole size I don't believe makes any difference. It just needs to be consistant for all lines/carbs. Different engines and different line/fitting sizes are going to effect the setting, but the balancer needs reset every time used anyway. Tipicaly one would get the engine running consitantly and then adjust the ballancer by hooking one hose up at a time and adjusting the ball leavel this way all 4 are adjusted the same since they all show the same leavel when hooked up to the same carb one after the other. Then they can all be hooked to a cylinder and the difference in carb balance viewed and adjusted.

I hope we are talking about the floating ball type balancer. that's what I had.

- Joined

- Jun 7, 2016

- Messages

- 361

Hi Russ

I actually have a set of gauges (two) and with the 1200 I connect a line to each throttle body and adjust the opening of the butterflies so they open as near as possible to the same time - it certainly makes the bike run smoother - so something is working. Want to be able to do the same thing on the old bikes, but need to fit these vacuum spigots first.

I think you are right about the hole size - as long as both holes are the same it will be fine. Thanks for taking the time to write a reply.

Mal

I actually have a set of gauges (two) and with the 1200 I connect a line to each throttle body and adjust the opening of the butterflies so they open as near as possible to the same time - it certainly makes the bike run smoother - so something is working. Want to be able to do the same thing on the old bikes, but need to fit these vacuum spigots first.

I think you are right about the hole size - as long as both holes are the same it will be fine. Thanks for taking the time to write a reply.

Mal