- Joined

- Mar 25, 2018

- Messages

- 5

Gidday!

I've had my "Big Dog" 7x lathe for several years, and have gotten to know the things that needed to be upgraded or replaced as I broke them. One thing I have barely touched on is threading. Dozens of time I have tried setting up to try but have run into various problems with the very loose tolerances in the machine being discovered or those of operator error. More recently, I have made "made a point" to learn how to thread using the lathe and complete an important project that a die set cannot.

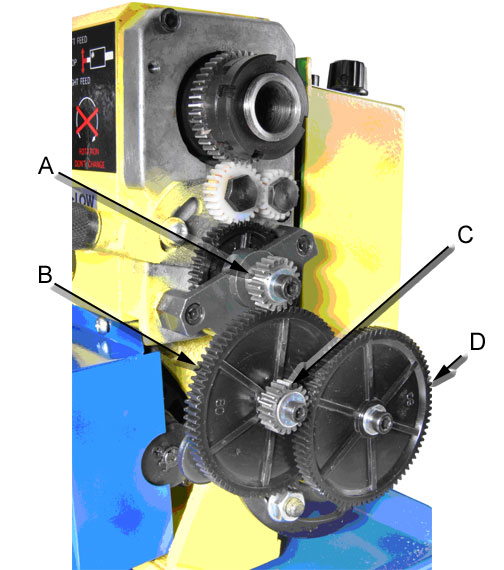

First problem was understanding how to swap the plastic gear configurations and all the related quirks. Second has been apparent slop in the gears when setting up for threading, which has been fixed here and there where possible. Then, after jumping out of gear with any force, I have significantly improved the FWD/REV selector engagement. Other gears are either wobbling or moving in ways they shouldn't be and am looking at replacing the related parts.

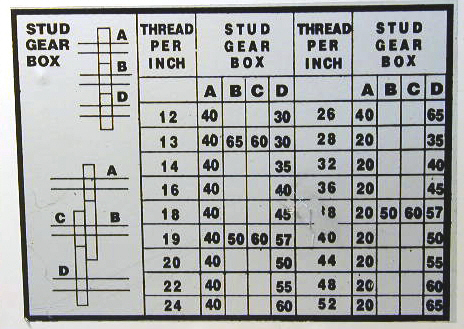

Currently setting the lathe up for threading 20tpi for a project according to the chart on the machine. During testing, the torque required of the motor seems excessive, and used my hand-wheel attachment. Much worse, the scribed lines on the shaft look much more like 24tpi. The gear tooth count was verified according to the chart on the cover. Since there has to be gears between A and D somewhere, I used the 50/60 gears from the 19tpi line. My assumption is that I must be misunderstanding the chart, or the leadscrew is not the correct one.

I would appreciate experienced input on this common mini lathe process!

I've had my "Big Dog" 7x lathe for several years, and have gotten to know the things that needed to be upgraded or replaced as I broke them. One thing I have barely touched on is threading. Dozens of time I have tried setting up to try but have run into various problems with the very loose tolerances in the machine being discovered or those of operator error. More recently, I have made "made a point" to learn how to thread using the lathe and complete an important project that a die set cannot.

First problem was understanding how to swap the plastic gear configurations and all the related quirks. Second has been apparent slop in the gears when setting up for threading, which has been fixed here and there where possible. Then, after jumping out of gear with any force, I have significantly improved the FWD/REV selector engagement. Other gears are either wobbling or moving in ways they shouldn't be and am looking at replacing the related parts.

Currently setting the lathe up for threading 20tpi for a project according to the chart on the machine. During testing, the torque required of the motor seems excessive, and used my hand-wheel attachment. Much worse, the scribed lines on the shaft look much more like 24tpi. The gear tooth count was verified according to the chart on the cover. Since there has to be gears between A and D somewhere, I used the 50/60 gears from the 19tpi line. My assumption is that I must be misunderstanding the chart, or the leadscrew is not the correct one.

I would appreciate experienced input on this common mini lathe process!

No extras , had to machine a longer shaft to get the line going . First night back from vacation is always a blast .

No extras , had to machine a longer shaft to get the line going . First night back from vacation is always a blast .