- Joined

- Aug 27, 2021

- Messages

- 5

Hello everyone, Matt in California, just getting started and looking for some additional guidance.

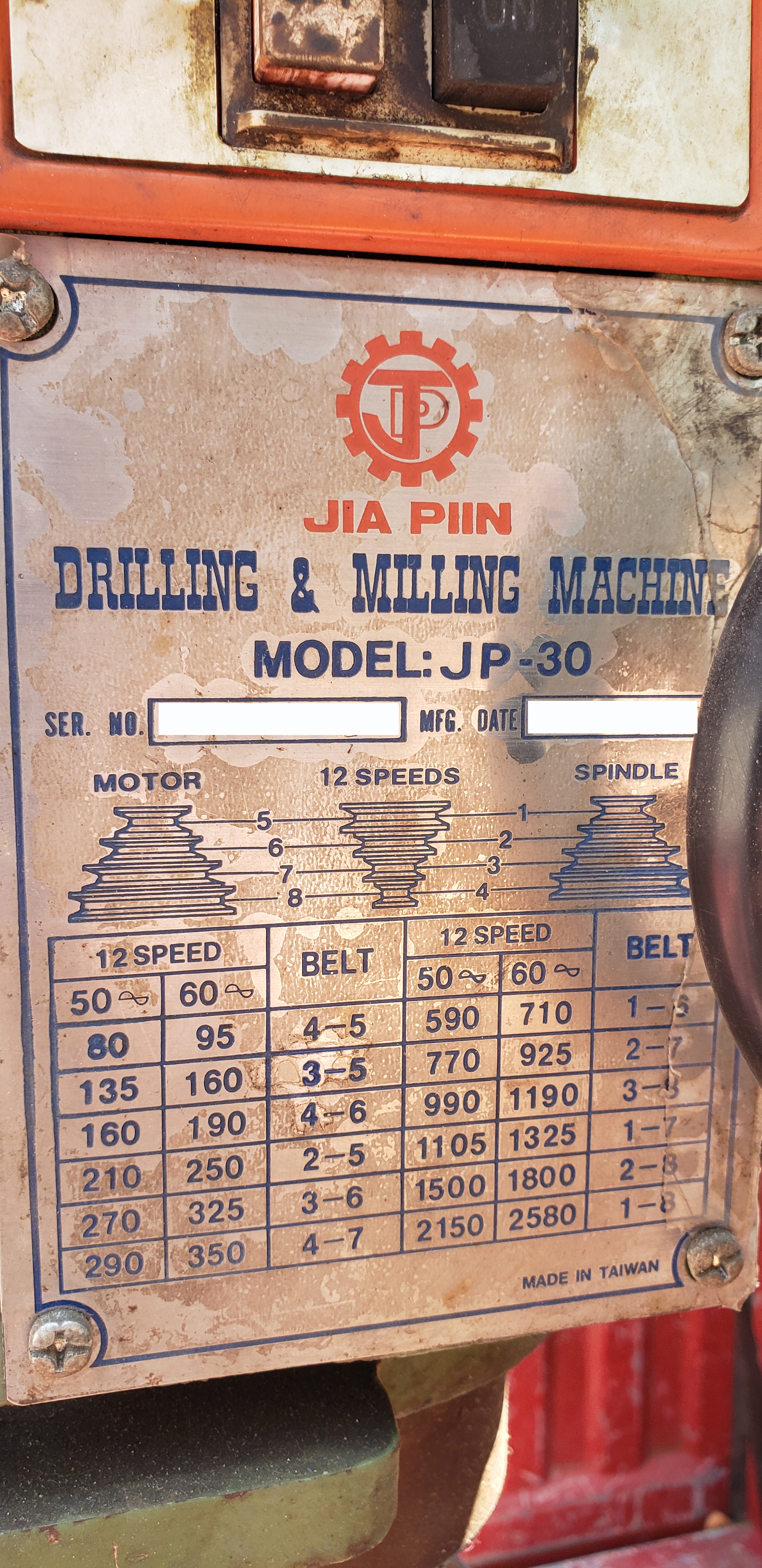

Picked up my first drilling and milling machine. But getting started has been quite the challenge.

Someone once told me "If it isn't on Google, then it probably doesn't exist." Well, this particular Jia Piin JP-30 isn't on Google, and it didn't come with a chuck.

Best as I can tell it seems to accept a MT2 spindle, with a Gage Line Diameter of 0.7370". While I did not scope it to see if it would accept tang, the total depth appears to be 3.550". I understand a true MT2 should have Gage Line of 0.700" and 2-15/16" depth.

Does anyone have addition information on this machine, or can point me in the right direction? I reached out to Jia Pin (hoping they are the same as Jia Piin), but so far no answer.

Thank you,

Matt

Picked up my first drilling and milling machine. But getting started has been quite the challenge.

Someone once told me "If it isn't on Google, then it probably doesn't exist." Well, this particular Jia Piin JP-30 isn't on Google, and it didn't come with a chuck.

Best as I can tell it seems to accept a MT2 spindle, with a Gage Line Diameter of 0.7370". While I did not scope it to see if it would accept tang, the total depth appears to be 3.550". I understand a true MT2 should have Gage Line of 0.700" and 2-15/16" depth.

Does anyone have addition information on this machine, or can point me in the right direction? I reached out to Jia Pin (hoping they are the same as Jia Piin), but so far no answer.

Thank you,

Matt