Hey,

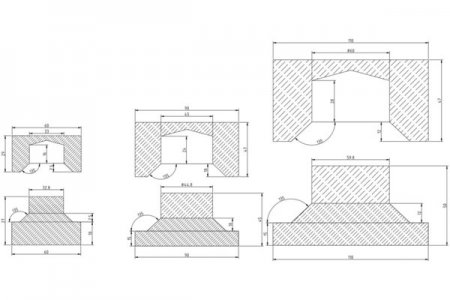

I have had go at making 2 dimple dies, but I got the angle portion wrong I keep machining it too big before I cut the angle, hope that made some sence

It is such a simple task but I just can't seem to get it right.

I machined it in steps then tried to cut the angle on the male die but either come up too short or too big

If I was on a PC i would draw something to explain what I'm doing wrong

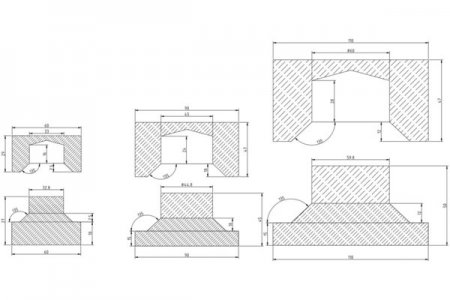

I have had go at making 2 dimple dies, but I got the angle portion wrong I keep machining it too big before I cut the angle, hope that made some sence

It is such a simple task but I just can't seem to get it right.

I machined it in steps then tried to cut the angle on the male die but either come up too short or too big

If I was on a PC i would draw something to explain what I'm doing wrong