-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ditron D80 DRO linear compensation...help?

- Thread starter Winegrower

- Start date

Is this just an issue with magnetic scales? Are any of you with this issue using glass scales?

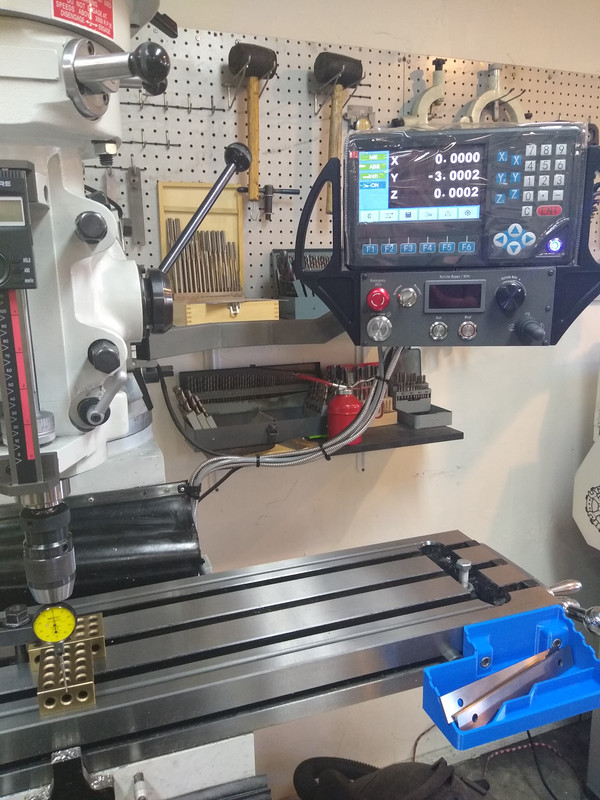

I have Ditron D80 displays from DRO Pros, on both my mill and lathe, but am using them with glass scales.

I'm using 1um glass scales and found it necessary to make an adjustment to the "Y" axis. The "X" axis was fine from the start. As mentioned earlier I have to recheck the accuracy against the blocks.

- Joined

- Jul 29, 2014

- Messages

- 2,725

My issues were only with magnetic scales, did not try glass. And for completeness, they were the smaller magnetic scales, don't recall the trade name.

- Joined

- Apr 23, 2018

- Messages

- 6,506

There is a backing strip, the encoder strip, and the stainless guard strip that are all supposed to be adhered together in the scale, but as @JimDawson pointed out, they can be forced to moving. I don't think they move under operation (air gap between reader and encoder), but I haven't verified that they don't move. I'm having second thoughts, so I will have to come up with some sort of test to see what I get. The problem is that once I get over 1", where I have gauge blocks good to .0001", I drop to .001" resolution up to 12" (using calipers or a depth gauge). That's a configuration that would be blind to step losses at 4um, the resolution of the scale. Hmmm. I suppose I have to define an acceptable cal range. Perhaps .001" in 4" would work for most real-world tasks.I have noted that by pressing with a finger on the magnetic strip a few inches away from the read head will show a change in the DRO reading. Putting some wipers on either side of the read head might be helpful, but I have not seen a problem on my mill with the strip exposed to everything.

- Joined

- Jan 6, 2017

- Messages

- 1,214

I'm using 1um glass scales and found it necessary to make an adjustment to the "Y" axis. The "X" axis was fine from the start. As mentioned earlier I have to recheck the accuracy against the blocks.

I went out and checked by touching off a 1-2-3 block with my edge finder. Across the 1" side, on the Y axis it was perfect. Showed 1.2000", with a .2 diameter edge finder tip.

Across the 3" side on the X axis It showed 3.1998". So, .0002" of error.

I did it several times with exactly the same results. That's with 5 micron scales.

I'll recheck occasionally, and consider myself fortunate.

Last edited:

- Joined

- Jan 6, 2017

- Messages

- 1,214

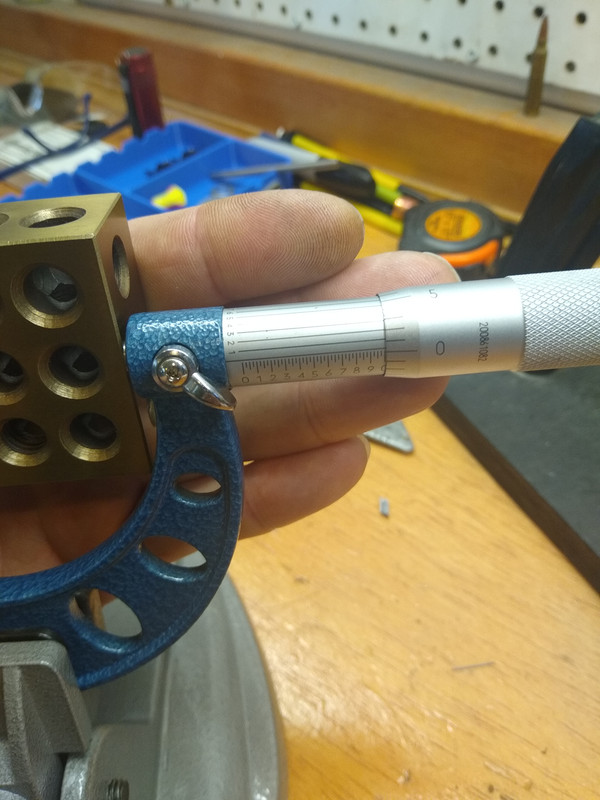

Use a tenths indicator, much more accurate.

Here's a video that shows the way to test scales.

I went out and set up a a DTI this morning and rechecked.

Using that method, my X axis shows .0004" and Y shows .0002". I suppose I should actually go measure the actual length of the Shars 1-2-3 blocks before I assume anything about scale error.

Edited to add: both my 1-2-3 blocks mic'd @ 3.0002" long on the 3 inch side.

find the gas station closest to me

find the gas station closest to me

Last edited:

- Joined

- Jul 29, 2014

- Messages

- 2,725

Ultimately I stuck a strip of electrical tape over the side of the scales…not the surface the reader moves along. I think this keeps tiny ferrous particles away from the magnetic strip where they can slightly distort the field. It helped a lot, to the point I don’t worry about it anymore.