- Joined

- Nov 15, 2016

- Messages

- 943

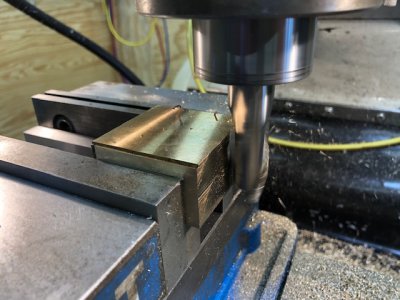

Pull it out and give it a turn and it should lock in position. Use the handle opposite to turn.The pin with the lockout for the dial always seems to snap free when turning it, not sure if I'm doing it wrong or if there is some sort of adjustment?