- Joined

- Mar 26, 2018

- Messages

- 8,407

It works.I'll wear my motorcycle helmet.

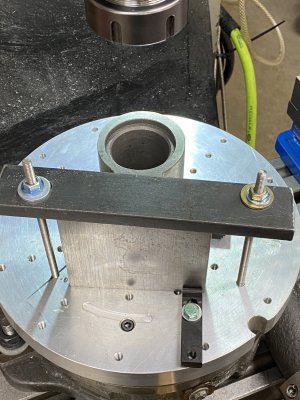

I don't have a lot of confidence in these Chinesium expanding mandrels.

But, we'll move forward.

Thanks man

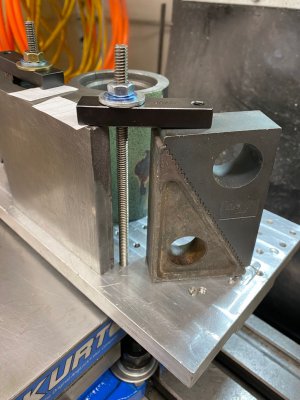

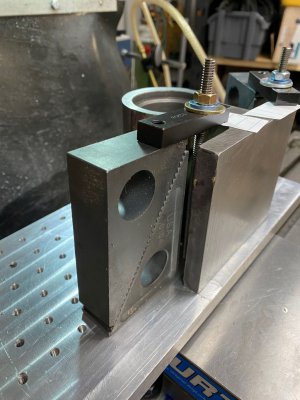

The spin index runs concentric!!

I think I'll run it around 140. If I take it easy I should be ok. Sharp HSS is the idea.

Now to do the math and work out the bushings, the oring specs etc.

This is the fun part