- Joined

- Jul 28, 2017

- Messages

- 2,368

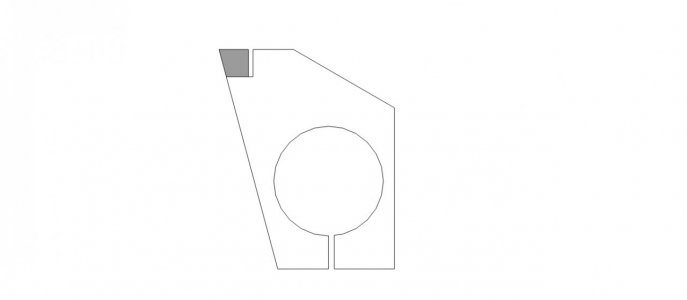

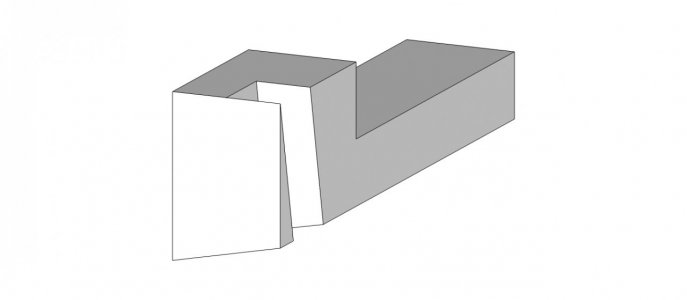

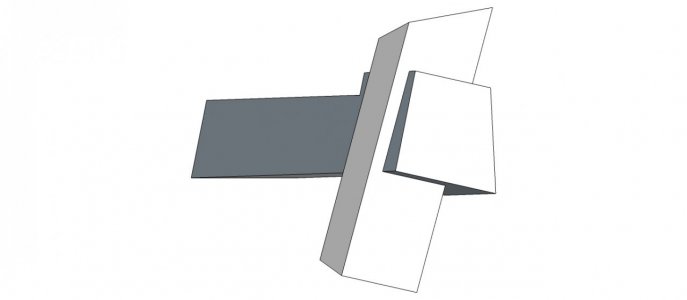

Yes, the usual approach is to employ a compound angle to get the job done. But your rendering doesn't look quite right to me -- the cutter's angle component ponting to the right is OK, but shouldn't the other angle be reversed, so the cutter points toward the viewer?I also use a norman style QCTP. In addition to the typical square or rectangular holders I have made them with an angle on one side.

View attachment 405482

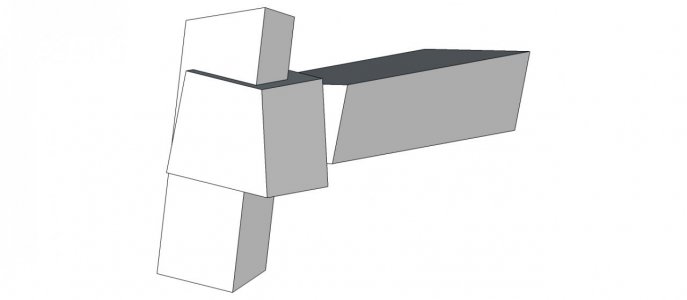

Could do something similar for a tangential tool holder.

View attachment 405483

The whole idea of my proposed alternative was to avoid a compound angle, relying on a rotation of the tool holder to provide clearance and provide a kinda-sorta compound angle. I think the scheme would work OK in some cases but it wouldn't be good for an all-around cutter. But that's not a total loss -- after all, a boring bar isn't all that great for an all-around cutter either.....