Like every 10-12" Atlas/Craftsman lathe, the gearbox on mine was broken in 4 different pieces when I got it. To get it up an going I tried "brazing" it back together using MuggyWeld. This worked for a while, but several of the places broke again and I knew it was time for something different. I had seen on eBay and other places that people sold replacements from aluminum for $$$. I wanted to see if I could make one for myself, but decided to use steel. Probably overkill, but in the words of Tom Lipton "nothing overbuilt ever broke."

Here's where I'm starting. You can see where I repaired and re-repaired the original part.

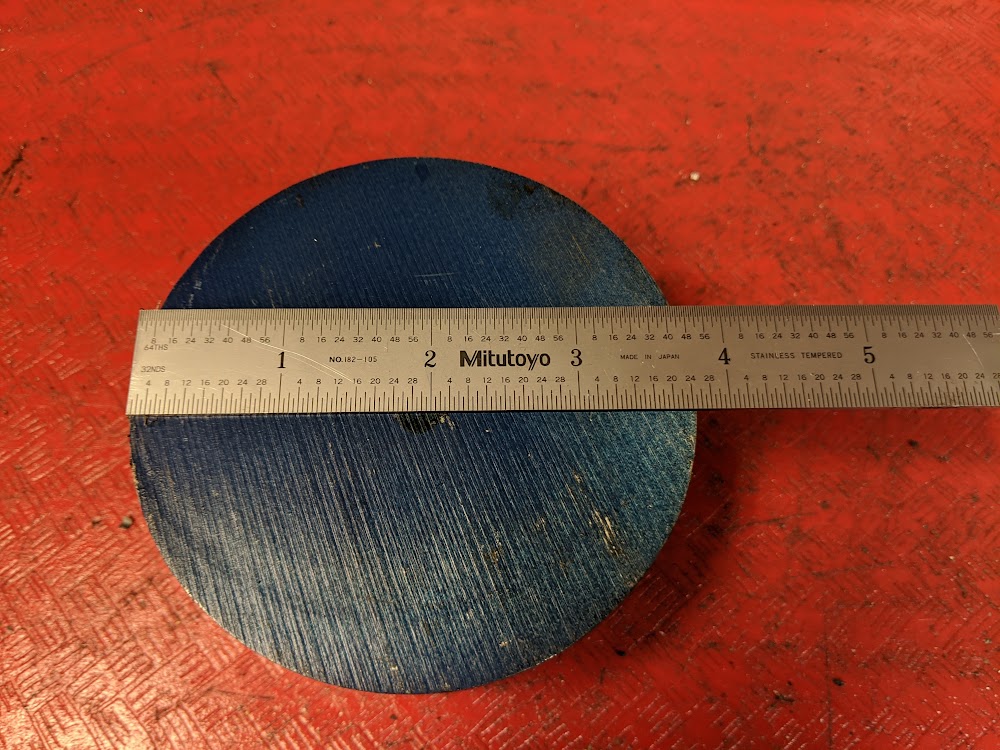

I came across a thread on another forum where someone had posted a drawing of the part, which would make my life much easier. I also liked that this design incorporated the use of bronze bushings for the gear shaft. For material, I got a 1.5" thick section of 1144 steel 3.75" in diameter. It was very inexpensive and a wonderful material to work with. Yes it would have been easier to start with a rectangular block, but this was much cheaper.

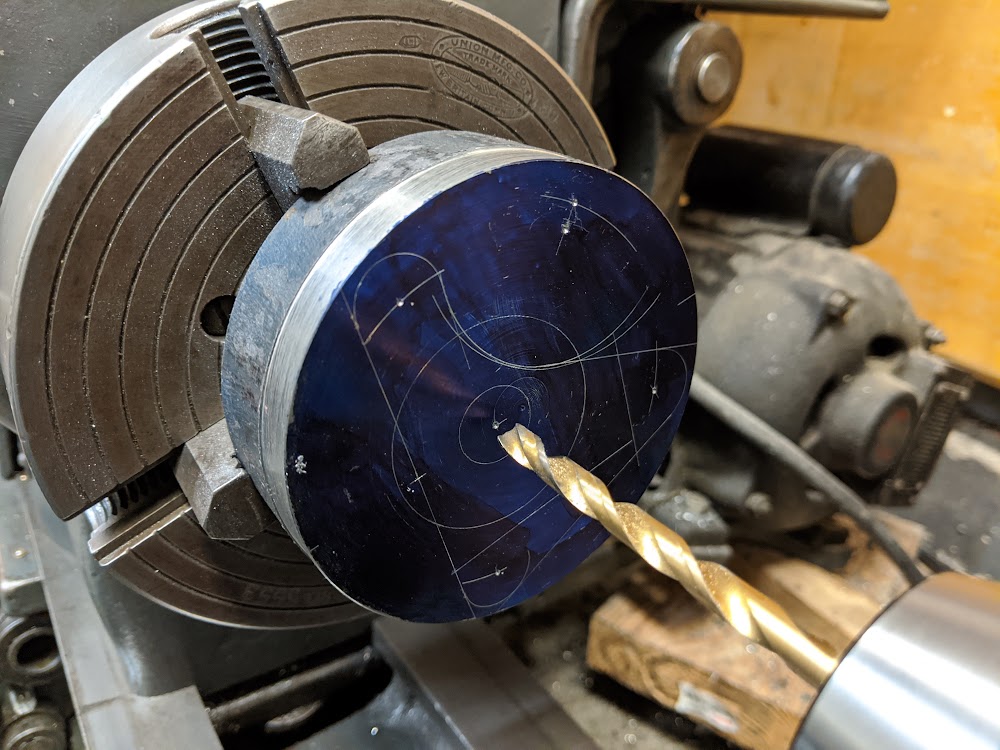

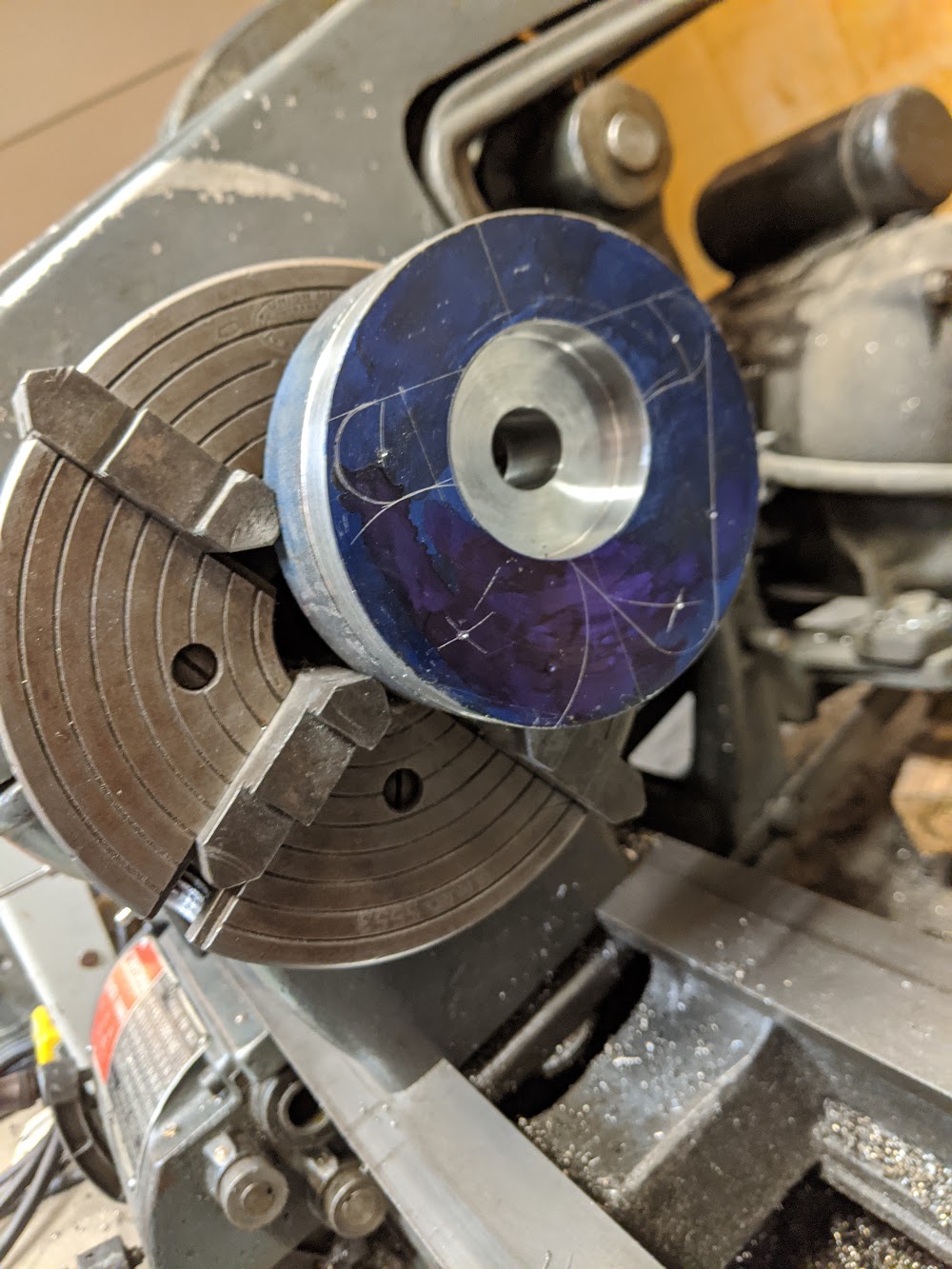

After facing it off and doing some layout, I got to work. It's fun using the machine to fix itself.

Fortunately before I started the large radius on the side, I realized that I had laid out the mirror image. It was a quick fix to swap that around and come up with this sketchy setup. No drama, but I didn't run it above 80RPM so it took a while. No pictures of the machining because I was too focused on not screwing up.

Here's where I'm starting. You can see where I repaired and re-repaired the original part.

I came across a thread on another forum where someone had posted a drawing of the part, which would make my life much easier. I also liked that this design incorporated the use of bronze bushings for the gear shaft. For material, I got a 1.5" thick section of 1144 steel 3.75" in diameter. It was very inexpensive and a wonderful material to work with. Yes it would have been easier to start with a rectangular block, but this was much cheaper.

After facing it off and doing some layout, I got to work. It's fun using the machine to fix itself.

Fortunately before I started the large radius on the side, I realized that I had laid out the mirror image. It was a quick fix to swap that around and come up with this sketchy setup. No drama, but I didn't run it above 80RPM so it took a while. No pictures of the machining because I was too focused on not screwing up.