- Joined

- May 7, 2014

- Messages

- 776

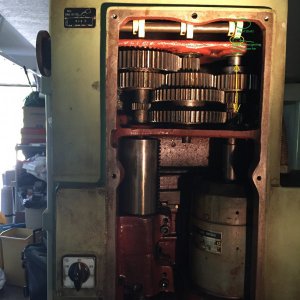

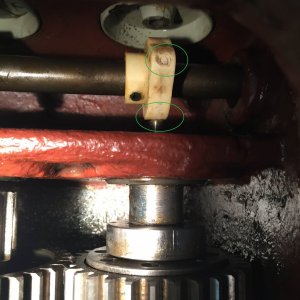

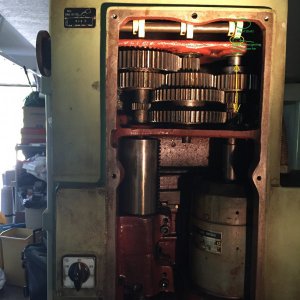

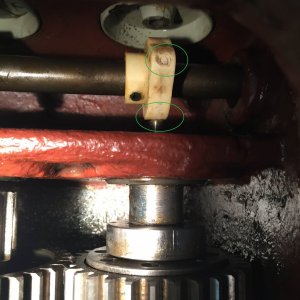

Picked up a winner w/ a possible easy-fix! Two speeds on this DoAll DGP-24 do not work. They are both related to the worn CAM end shown in the pictures below. Seller thought it had a broken gear.... 3 franklins + I move it out made it mine. Love this stuff!

Should be an easy fix if I can get something to fill in the Divot, stick, and take lube. The rod that the cam pushes down does spin while in contact w/ the plastic cam. I have a feeling it was just left in that speed since the 80's?

Do we have JBWeld believers? I do have the West epoxy System which I could mix up too. Or? what else could I do to fill in the two divots on each plastic CAM point. Two of them are 1/8"-3/16" or so worn.

I did confirm this will fix the missing two speeds by just putting a shim between the pin and cam... Bingo!

Whatever I fill in w/ will need to be oiled and take a bit of punishment.

I could make a new plastic CAM on the CNC Mill, but then I'll need to rip and replace. Want to try epoxy maybe as this is a home/hobby drill setup. Not a full time thing.

Should be an easy fix if I can get something to fill in the Divot, stick, and take lube. The rod that the cam pushes down does spin while in contact w/ the plastic cam. I have a feeling it was just left in that speed since the 80's?

Do we have JBWeld believers? I do have the West epoxy System which I could mix up too. Or? what else could I do to fill in the two divots on each plastic CAM point. Two of them are 1/8"-3/16" or so worn.

I did confirm this will fix the missing two speeds by just putting a shim between the pin and cam... Bingo!

Whatever I fill in w/ will need to be oiled and take a bit of punishment.

I could make a new plastic CAM on the CNC Mill, but then I'll need to rip and replace. Want to try epoxy maybe as this is a home/hobby drill setup. Not a full time thing.