I’m hoping someone can help me out here. I just finished making a 2x72 belt grinder that is powered by a 220v 30 amp VFD. I also have a grizzly mill that is powered by 220v 30 amp. I’d like to have the 220 extension cord that hangs down from the ceiling above both of them power them both but not at the same time. I’d like to have a box I can mount that has two plug ins on it but then has a DPDT switch to control both plug ins. That way I could have both machines plugged in at the same time but use the switch to power the grinder or to the mill or center for off. I also would like this because the vfd for the grinder doesn’t have an off switch. It has to be unplugged to turn off. Wondering if this is even possible. Did some research but can’t come up with much. Thanks for any help.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Double 220 plug in for mill and grinder

- Thread starter Brett

- Start date

- Joined

- Sep 2, 2013

- Messages

- 5,090

Something like this, but in a 30 amp version. https://www.bluesea.com/products/9077/AC_Rotary_Switch_-_OFF_+_3_Positions_240V_AC_65A

- Joined

- Apr 30, 2015

- Messages

- 11,252

Brett: This is not a great idea for a couple reasons:

A) Turning off the belt grinder by opening the connections from the VFD to the motor would likely blow up the VFD- you would need to turn it off at the VFD itself.

B) Similar situation with the mill- possible damage to the VFD if you were to switch the loads with the motor still coasting down and VFD on

Most folks have a dedicated VFD for each motor/machine with no switches between motor and VFD output

-mark

A) Turning off the belt grinder by opening the connections from the VFD to the motor would likely blow up the VFD- you would need to turn it off at the VFD itself.

B) Similar situation with the mill- possible damage to the VFD if you were to switch the loads with the motor still coasting down and VFD on

Most folks have a dedicated VFD for each motor/machine with no switches between motor and VFD output

-mark

- Joined

- Feb 13, 2017

- Messages

- 2,138

Something like this, but in a 30 amp version. https://www.bluesea.com/products/9077/AC_Rotary_Switch_-_OFF_+_3_Positions_240V_AC_65A

That looks to be the optimal solution. The only input I can make is to go with the higher current rating. It (used to be) general practice to use larger contacts than the rating of a machine to ensure longevity. If the load is switched while off, the damage to contacts is minimized. But my experience is that there is always an unexpected exception and things get switched under load

There is a slight degradation of contacts every time they are cycled. Very slight, but over time can add up to trouble. The closer to maximum capacity a contact is operated, the more likely the damage to occur. It isn't really exponential, but that is a good way to describe it.

My opinion, based on 50+ yrs experience, is to use the heaviest contact you can find space for and forget about maintenance. Which usually doesn't happen anyway, it's usually "corrective maintenance". (Fancy name for repairs)

This is assuming you want to switch the line side of the VFD. The load side of the VFD is not a good idea in that each motor has to be tuned into the VFD. There are other foibles to operating a VFD into an open circuit, however quickly, that I am not qualified to comment on.

.

.

Last edited:

- Joined

- Apr 23, 2018

- Messages

- 6,510

The only way I know how that would work legally is to install a double throw safety disconnect switch rated for the full load of your machines on the wall, and run two drops to your equipment from there. It's bulky and rather expensive.

I've run double 220v outlets on one cord, that part is doable; it's the switching that would get wonky. Putting a switch on the grinder (either with a new VFD or by restoring function to the master power on the grinder) would probably be the better choice.

@Bi11Hudson: Ha ha, corrective maintenance. In the Army, we called it unscheduled maintenance.

I've run double 220v outlets on one cord, that part is doable; it's the switching that would get wonky. Putting a switch on the grinder (either with a new VFD or by restoring function to the master power on the grinder) would probably be the better choice.

@Bi11Hudson: Ha ha, corrective maintenance. In the Army, we called it unscheduled maintenance.

- Joined

- Feb 1, 2015

- Messages

- 9,575

A transfer switch used to switch between mains and auxiliary power could be used.

Reliance Controls 60 Amp Utility / Generator Transfer Switch TCA0606D - The Home Depot

This 60-Amp, double-pole manual transfer switch is for use with any 125/240V generator up to 15,000 running Watts. Ideal for switching a 60A service or subpanel from utility to generator power. This economical

www.homedepot.com

- Joined

- Jan 14, 2019

- Messages

- 104

Hi fellow Minnesotan! For my mill, lathe and sg, I have one 220 volt 30 amp circuit that has three separate female plugs in line. Each plug has a cord going to a separate VFD for each machine. I only run one machine at a time. None of my VFDs have an “off” mode, they are all left on and basically sit dormant with only the screen using power. I know some people are not a fan of this method. From talking to the tech dept for the VFDs, it is not a concern to simply leave them on and not running. It is like my microwave, I never unplug it or turn it off.

Ryan

Ryan

- Joined

- Feb 17, 2013

- Messages

- 4,406

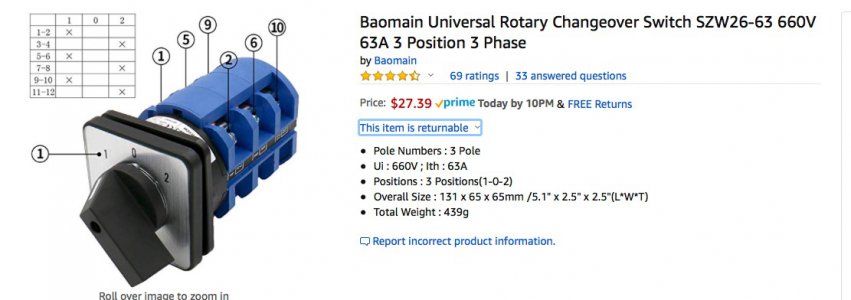

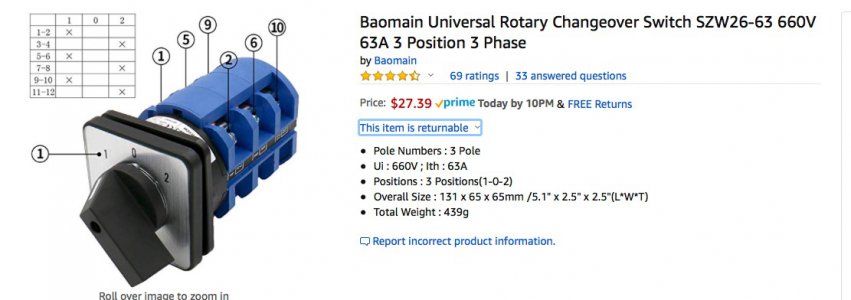

Here's a switch that's claimed to be rated for 63 amps, bargain priced at $27.39

You'd wire L1 (in) to terminals 1 and 3, L2 (in) to 5 and 7. Grinder wired to 2 and 6. Mill wired to 4 and 8. Terminals 9,10,11,12 not used.

The rated power would give you a good operating margin (per Bi11Hudson). I'm just not absolutely sure I believe that current rating, especially given the low price. Caveat emptor.

Baomain Universal Rotary Changeover Switch SZW26-63 660V 63A 3 Position 3 Phase: Amazon.com: Industrial & Scientific

Baomain Universal Rotary Changeover Switch SZW26-63 660V 63A 3 Position 3 Phase: Amazon.com: Industrial & Scientific

www.amazon.com

You'd wire L1 (in) to terminals 1 and 3, L2 (in) to 5 and 7. Grinder wired to 2 and 6. Mill wired to 4 and 8. Terminals 9,10,11,12 not used.

The rated power would give you a good operating margin (per Bi11Hudson). I'm just not absolutely sure I believe that current rating, especially given the low price. Caveat emptor.

- Joined

- Dec 12, 2016

- Messages

- 493

Just make yourself an extension that has 2 outlets on it and only turn one machine on at a time.

My whole shop is on one 220 feed.

Worst case you might have too many things running and blow the breaker.

You probably don't want to try to get a single VFD to power multiple machines, you should use a separate VFD for each machine.

My whole shop is on one 220 feed.

Worst case you might have too many things running and blow the breaker.

You probably don't want to try to get a single VFD to power multiple machines, you should use a separate VFD for each machine.

Thanks everyone for the answers. Lots of good info. I just want to clarify a couple things. I’m only running on VFD on my grinder and it is only used to power the grinder. Basically right now I have an extension cord that hangs down from the ceiling. My grinder and mill sit below it back to back. When I want to use the mill I plug it in and use it. When I want to use the grinder I unplug the mill and plug in the grinder and when I’m done I could just unplug it. My idea was to have the extension cord from the ceiling go to a box that would have two outlets on it. With both machines plugged into those outlets. With having a switch on the box I could have it in the off position when I’m not using either machine. When I wanted to use one simple turn the switch to power the outlet that machine is on. Hope that makes sense. I think that rotary change over switch may be the answer.