- Joined

- Apr 4, 2016

- Messages

- 843

I would use this type of safety switch for your application: https://www.eaton.com/us/en-us/cata...ols-systems/double-throw-safety-switches.html

Ted

Ted

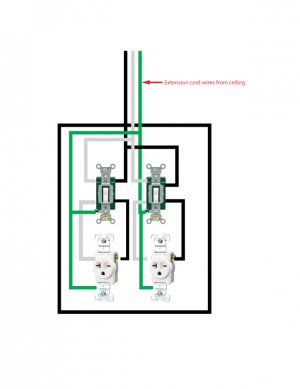

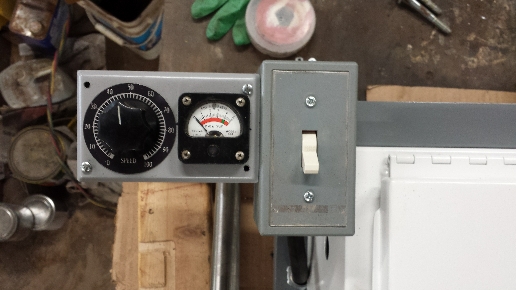

Thanks everyone for the answers. Lots of good info. I just want to clarify a couple things. I’m only running on VFD on my grinder and it is only used to power the grinder. Basically right now I have an extension cord that hangs down from the ceiling. My grinder and mill sit below it back to back. When I want to use the mill I plug it in and use it. When I want to use the grinder I unplug the mill and plug in the grinder and when I’m done I could just unplug it. My idea was to have the extension cord from the ceiling go to a box that would have two outlets on it. With both machines plugged into those outlets. With having a switch on the box I could have it in the off position when I’m not using either machine. When I wanted to use one simple turn the switch to power the outlet that machine is on. Hope that makes sense. I think that rotary change over switch may be the answer.

The VFD doesn’t have a power off switch. When it is plug in it is on and the fan is running too which is why I don’t want to leave it plugged in. The mill is kind of the same way. When it is plugged in the light on the mill is on showing power going to the mill. Probably not a big to leave that on since it’s just a power light but my ideal plan would be this. Use a splitter at the extension cord for the ceiling. Plug in both machines but have some kind of inline switch on each machine plug wire so the power could be completely cut off from the machine. Something similar to this.I just re-read your first post- now I understand- but- your VFD must have a power switch or standby mode of some kind, does it not? As John mentioned above, in standby it should not need to be disconnected from the power line, since it draws only a tiny current. But yes, you can add a main switch for it if you want to turn it off completely. So you really just want to build a split outlet with a switch on one side for the VFD- I assume your mill has it's own power switch