- Joined

- Nov 24, 2014

- Messages

- 3,156

ranging from 5/32 to 7/32

Those are small enough diameters that you should be able to handle.

I suspect that major factors are less-than-sharp drill bits so you're advancing them with too much pressure.

Too much pressure results in the break-through happening with too much metal left to cut. In other words, as soon as the web breaks through, the cutting edges spiral through.

To test my theory, get some new, top quality bits, use a good lubricant (I like dark cutting oil as used in pipe threading), and let the bit cut. Don't 'push' the bit through. As was previously mentioned, it's key for you to develop a 'feel' and reduce your feed pressure as the web breaks through.

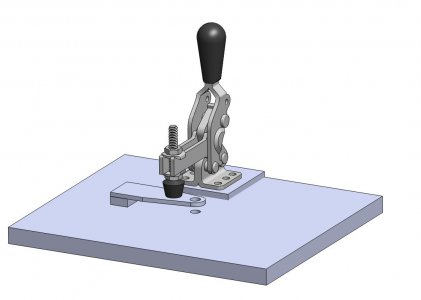

Obviously, it's good advice to rigidly secure your vise/work-piece but I understand the practicality of what you're trying to do. How about this? Bolt your DP vise to a base plate that extends beyond the back of the vise far enough to bear against the DP column (anti-torque). Additionally, tighten a collar around the column with just enough clearance to let the base plate slide between the table top and the collar (anti-lift). Many ways to skin that cat.