- Joined

- Oct 15, 2011

- Messages

- 153

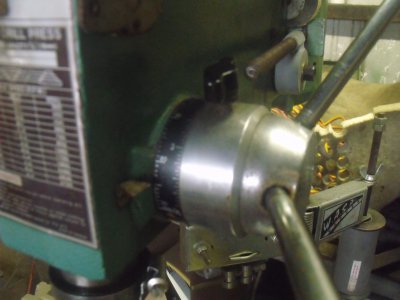

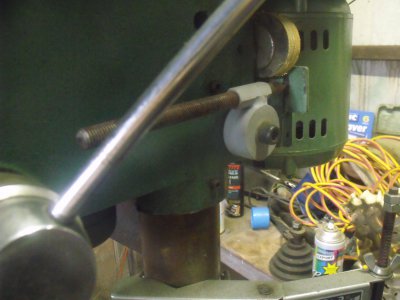

i have a drill press that has the boss for the 3 arms in rather a bad way.The metal for it is barely sheet metal and consequently the threaded holes are all sloppy. I am about to strip it down and machine something suitable in solid metal.

While I believe it will be straight forward I am concerned about the dis assembly of the return spring. Should I break it, are these things readily available. Is there any other advice kind souls would offer on this project.I have done some net searches but can't seem to find info on a similar project.

Cheers

Oz

While I believe it will be straight forward I am concerned about the dis assembly of the return spring. Should I break it, are these things readily available. Is there any other advice kind souls would offer on this project.I have done some net searches but can't seem to find info on a similar project.

Cheers

Oz