But I can see the end of the bits wobbling - it affects other work as well - more distressing are out of round holes in metals. I bought a set of reamers a couple weeks back & completely ruined a ram rod tube trying to ream it out ...

Sean, I totally agree with John re the deep holes. Accuracy with an Asian drill press in deep drilling is probably not gonna happen.

If your spindle is accurate, and 0.0005" is pretty good for a drill press, then an increase to 0.005" of run out on a rod in the chuck suggests that a) the arbor is bad, b) the chuck's internal taper is bad, c) that a and b are okay but the chuck was not mounted on the arbor accurately, d) the jaws are damaged or not holding the rod concentric to the chuck body, or e) the chuck is a POS and needs to be changed to a precision chuck.

You sort of need some frame of reference as to how much a properly mounted chuck in good condition will run out on an Asian drill press. There is no such standard, at least to my knowledge, but I have a Craftsman 15" drill press in which I replaced the spindle, spindle and drive sleeve bearings, mounted an Albrecht keyless chuck in pristine condition on a brand new Albrecht arbor with great care paid to how I installed the chuck in the spindle and I have under 0.0005" TIR at the arbor and under 0.001" on a 3/8" dowel pin measured 1/2" beyond the chuck. It is pretty accurate when drilling holes but even I understand that this only handles the driving end of the hole making process.

So, do you need a new chuck? Dunno', maybe. If your chuck is the OEM chuck that came with that drill press then I would say dump it and use an Albrecht, Rohm or Jacobs Super Chuck. The OEM Chinese chucks are worthless other than for drilling holes in wood, in my opinion. I would also dump that OEM arbor and get a decent one from Albrecht, Jacobs, Rohm or some other reputable maker.

The biggest issues when we get out of round holes are chatter and vibration. This has little to do with the drill press directly; it has more to do with the drills and how we use them. About 3-4 years ago, I looked into this subject and am "speaking" off the top of my head about what I recall but chatter is a really big deal. As you might expect, speeds have a lot to do with chatter. If you drill a partial depth hole and you see a sunray pattern, like spokes on a wheel, at the bottom of the hole instead of a smooth surface then you have chatter. Just like on a lathe, the solution is to reduce speed and increase feed. It may surprise you to find that this works rather well, crude as it may seem. This is why I tend to run my drills slower and feed harder nowadays and it works.

The other issue is vibration. As I recall, you can modify your tool web to be thicker and use less relief behind the cutting edge. I may be wrong on this but increasing the contact area at the cutting tip dampens vibration, leading to less out of roundness.

To be honest, I don't modify my drill geometry. Too lazy, I think. What works for me is:

- Use spotting drills to get my drill started well and I make sure the drill flute ends are buried in the hole before I clear chips the first time. This makes a hole my drill can re-enter accurately.

- Avoid pilot drills when I can. Pilot drills are thin and will wander, and any drill that follows will follow the same path. Using a main drill works better, for me at least.

- Use lower speeds and harder feeds. This works better than you might think.

- Clear chips after going in 2-3 drill diameters.

- Always use lube.

- For reamers, spot, then drill with a drill one size smaller than your pre-reamer drill to rough out the hole, then use your pre-reamer drill, then ream. I tried all kinds of things to figure out how to ream an accurate hole and this works best for me. I also run the reamer at about 100 rpm on the mill or the slowest I can on the drill press (about 250 rpm) and make a steady controlled pass on the infeed only, then I shut off the machine and manually withdraw the reamer. This gives me a better finish, a more accurate hole and my reamers stay sharp longer. I use a lot of lubricant, too.

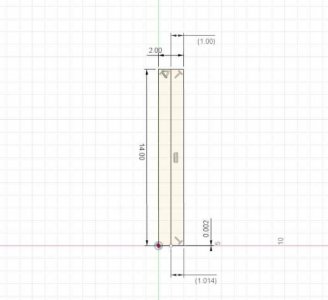

It matters which drills you use before running a reamer in the hole. See the attached file.

It sounds like you're a gun guy and I'm not sure which brand of reamer works best for your needs. For my simple needs, I prefer Alvord Polk, L&I and PTD reamers.