- Joined

- Nov 14, 2016

- Messages

- 2,996

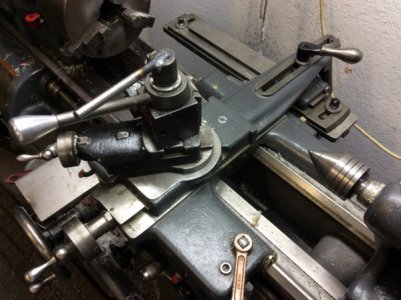

I want to make a T handled 14mm wrench to adjust the top nut on a quick release tool post.

I bought a 14mm deep socket at Home Depot which really is almost enough a tool to do the job as is, but where is the fun in that.

The cheapest, easiest way to do it would be to just drill a hole near the top insert a piece of rod and secure it.

I've considered other options including buying a 3/8" T handle hex key and cutting it off so the handle matches my other lathe / mill wrenches, but that is a $15 solution to a $1.99 problem (as if this whole project isn't a solution looking for a problem).

I'm just not sure how hard the metal of a socket is, practical to drill or not?

Home Depot, Husky brand socket, so on the lower end price wise, but generally decent quality.

If drilling the socket isn't a great idea, I can always use some key stock or similar to insert into the drive socket and drill through that. Going through the socket just looks cleaner and makes a slightly more compact tool.

I bought a 14mm deep socket at Home Depot which really is almost enough a tool to do the job as is, but where is the fun in that.

The cheapest, easiest way to do it would be to just drill a hole near the top insert a piece of rod and secure it.

I've considered other options including buying a 3/8" T handle hex key and cutting it off so the handle matches my other lathe / mill wrenches, but that is a $15 solution to a $1.99 problem (as if this whole project isn't a solution looking for a problem).

I'm just not sure how hard the metal of a socket is, practical to drill or not?

Home Depot, Husky brand socket, so on the lower end price wise, but generally decent quality.

If drilling the socket isn't a great idea, I can always use some key stock or similar to insert into the drive socket and drill through that. Going through the socket just looks cleaner and makes a slightly more compact tool.