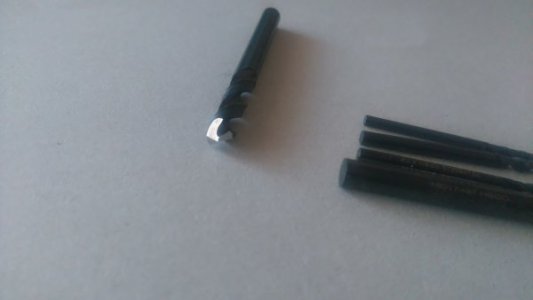

I'm modifying a Harbor Freight caliper to be used as a DRO on my lathe. A couple of 2 mm holes need to be drilled in it so it can be mounted to the cross-slide. The caliper is definitely hardened stainless. A TiN coated HSS drill doesn't do anything to it. What is the best way do drill small holes in this material? Will M35 Cobalt HSS work? Do I need carbide or diamond drills? Brittle carbide that small will probably be pretty tricky.

Thanks in advance for any help.

Glen

Thanks in advance for any help.

Glen