-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

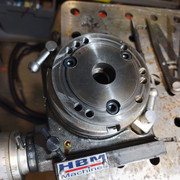

Drilling the 4" lathe chuck

- Thread starter Alberto-sp

- Start date

Hi Alberto.

An adapter plate is the way to go. I made one so I could fit a 160mm 3 jaw lathe chuck to a 150mm Vertex rotary table. It also allows for me to fit my 4 Jaw if needed.

I turned a plate from a piece of 20mm aluminium. From memory it was a grade that has properties similar to mild steel but easier to work and lighter.

The chuck mounting face is turned with a small lip to locate the chuck. This plate takes the place of the chuck back plate.

Special T nuts are made to fit the RT slots and extend up into the adapter plate.

Grub screws are screwed through the side of the plate and into holes in the T nuts. The grub screws have their ends tapered so that as they are tightened, they pull up on the T nuts, thus securing the plate against the RT.

I also turned a shaft with a 2MT to fit the centre of the RT. Clamp this lightly in the 3 jaw while tightening everything up and it is almost perfectly aligned.

Hope this all makes sense.

An adapter plate is the way to go. I made one so I could fit a 160mm 3 jaw lathe chuck to a 150mm Vertex rotary table. It also allows for me to fit my 4 Jaw if needed.

I turned a plate from a piece of 20mm aluminium. From memory it was a grade that has properties similar to mild steel but easier to work and lighter.

The chuck mounting face is turned with a small lip to locate the chuck. This plate takes the place of the chuck back plate.

Special T nuts are made to fit the RT slots and extend up into the adapter plate.

Grub screws are screwed through the side of the plate and into holes in the T nuts. The grub screws have their ends tapered so that as they are tightened, they pull up on the T nuts, thus securing the plate against the RT.

I also turned a shaft with a 2MT to fit the centre of the RT. Clamp this lightly in the 3 jaw while tightening everything up and it is almost perfectly aligned.

Hope this all makes sense.

Attachments

- Joined

- Apr 8, 2021

- Messages

- 138

- Joined

- Oct 13, 2014

- Messages

- 6,559

That is the back of it, the scroll part is facing the the backs of the jaws. If you open it all the way the jaws should slide out. Then you can see the front of the scroll in the back of the slots that hold the jaws and determine how much clearance there is to the outside of the chick body. Be sure to put the jaws back in the same slots as they came from, number them and the slots if they aren't already.Thanks for your answers.

I think there is no problem drilling it since the scroll plate is small. I check it out before.

You mean this right?

- Joined

- Apr 8, 2021

- Messages

- 138

- Joined

- Apr 8, 2021

- Messages

- 138