- Joined

- Jul 14, 2017

- Messages

- 2,446

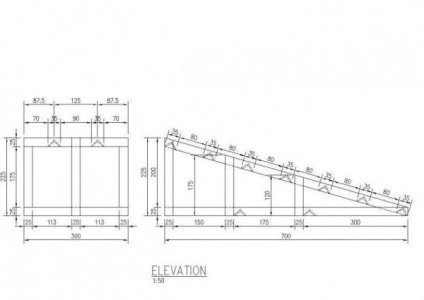

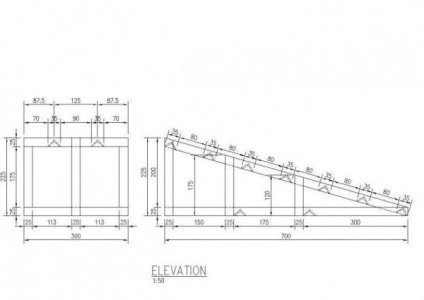

i'm in the middle of repairing an old small 4x4, i'm doing lot of the work on jack stands but i've come to a point where i need a wheel to roll on and off so i can check articulation and clarence, i've looked around to buy plastic ramps but only one store has them and they are only 10 centimeters high, i've searched google and found only this drawing, looks easy enough to fabricate but i'm concerned about stability side to side, i also want to use the same ramps on my cars for oil changes so i can't make them very high, i'm thinking 20 - 25 centimeters high and 25 centimeters wide, any advice or shared experience is much appreciated.