- Joined

- Apr 8, 2013

- Messages

- 1,977

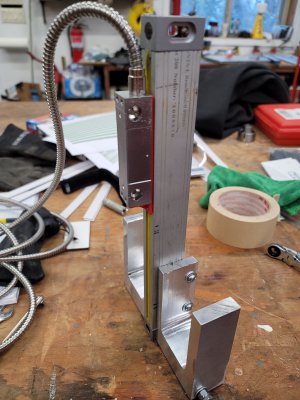

My install was similar. I replaced the feed rod with a 1/2 x 20 tpi rod and rebushed the holes for a better fit.On a DRO install in an RF30 clone, To mount the z axis scale, I replaced the depth rod with a length of 5/8" ground shaft. The through hole in the boss for the stop rod was enlarged to accommodate the shaft. The scale was mounted to a 3/8" x 1-3/8" x 12" 6061 bar which was mounted to the depth stop bracket along with the shaft. The upper end of the shaft supported the top of the bar providing a very stable mount for the scale. The depth rod was relocated and the stop nut replaced with two nuts and a tab which can swing in to engage the boss. It has the additional advantage of being able to limit upward travel as well as downward travel; useful when drilling multiple holes and you don't want the quill to return to its home position.

Last edited: