- Joined

- Jan 10, 2016

- Messages

- 29

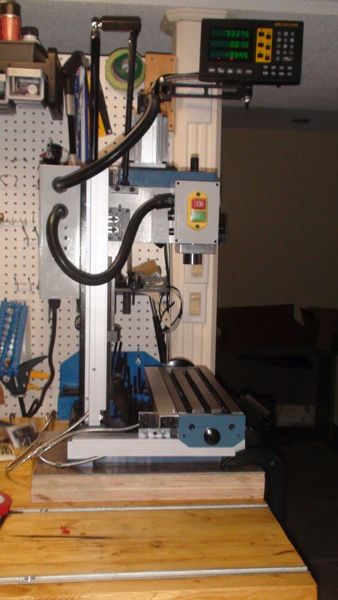

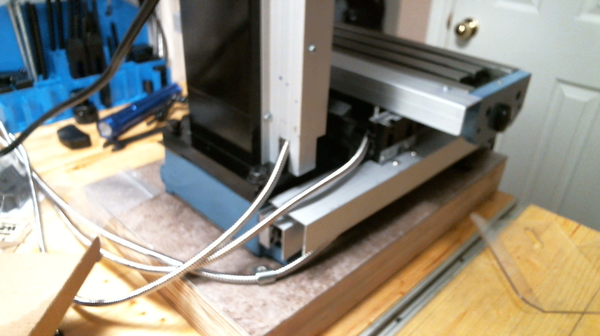

Just want to share my installation config of a magnetic DRO pro (3 axis kit, model EL400) on LMS 3990.

A big thanks to Joe Pitz, his post and his youtube video http://www.hobby-machinist.com/threads/little-machine-shop-hitorque-mini-mill-dro-install.36143/

This led me into the right direction (especially with regards to the Y-axis needing a separate base with set screws to correct the taper in the cast iron). I implemented this part the same way as he suggested.

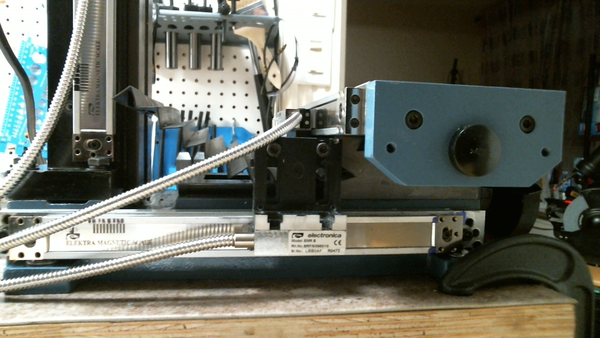

The differences in my config were due to the fact that I purchased a magnetic scales / readers option (while Joe's system is optical). This required somewhat different approach to mounting the rails, the reading heads and the covers. I have also chosen to mount both X and Y reader head mounting brackets at the back of the Y axis table to allow for an easier power feed installation, if I ever wanted to install one on the left side of the of x-axis table.

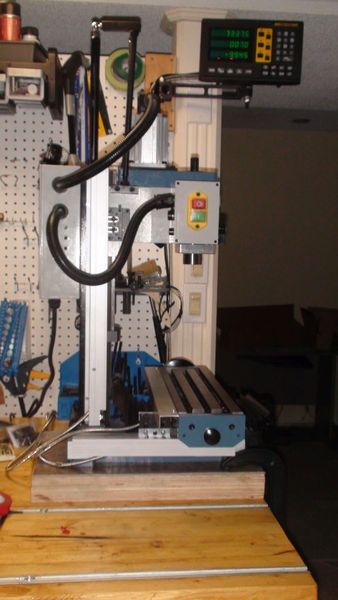

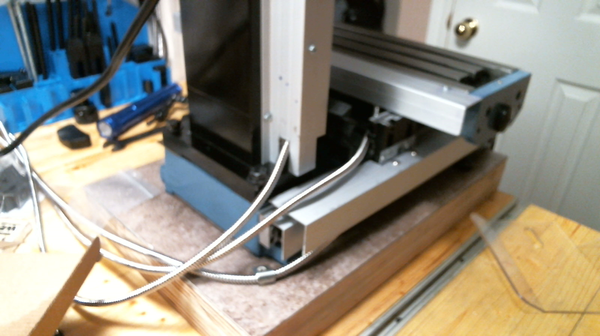

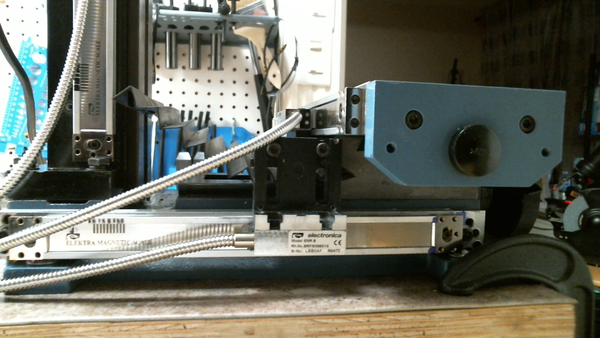

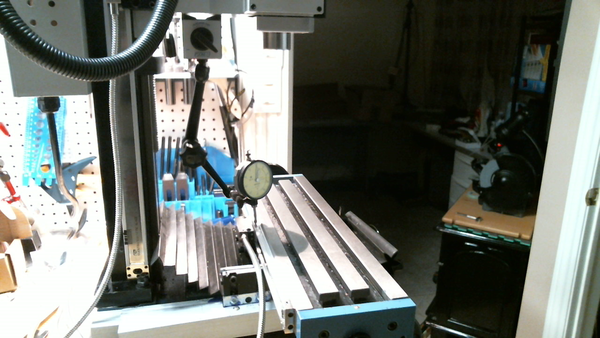

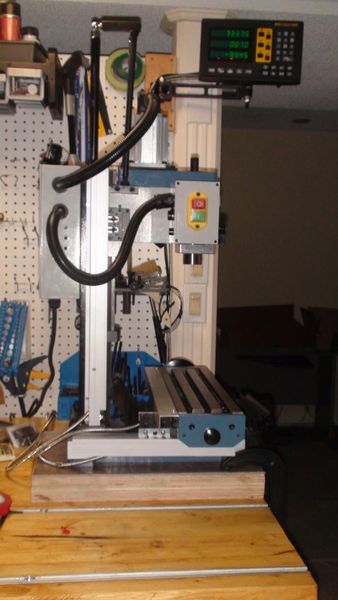

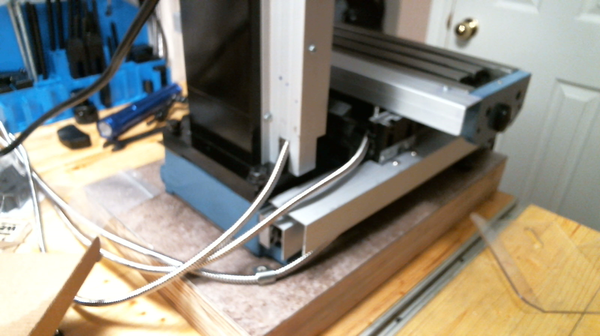

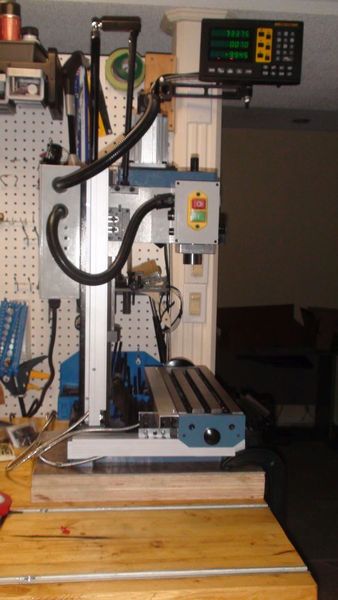

The finished product looks like this:

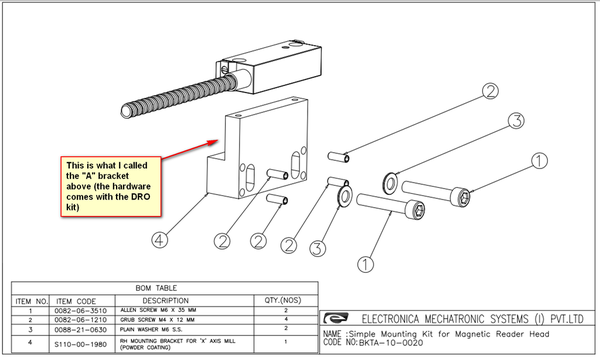

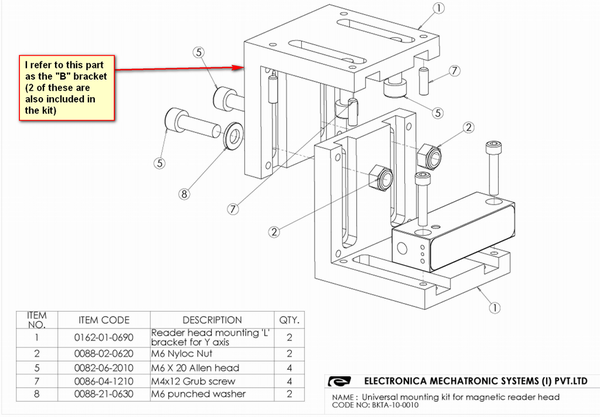

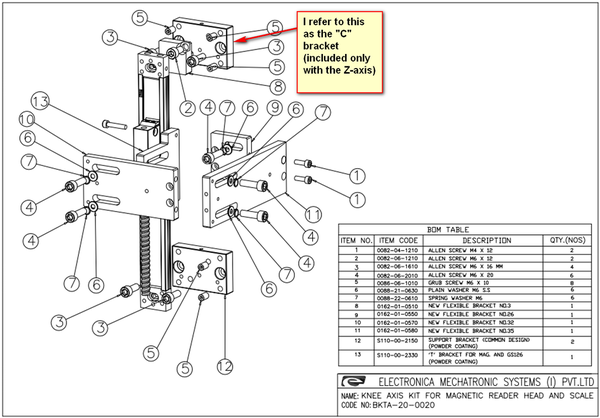

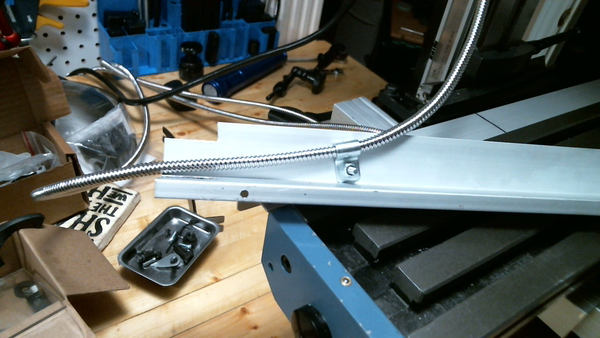

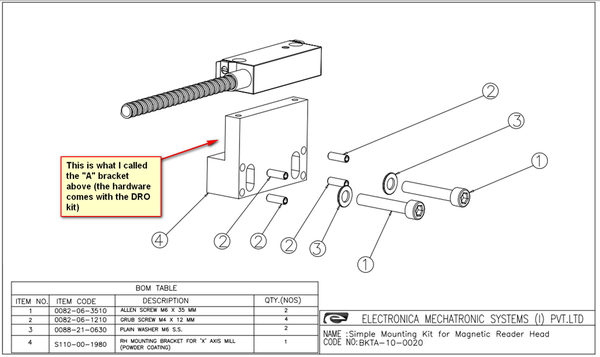

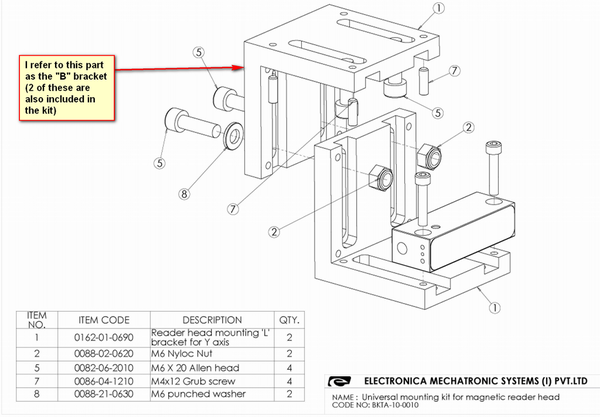

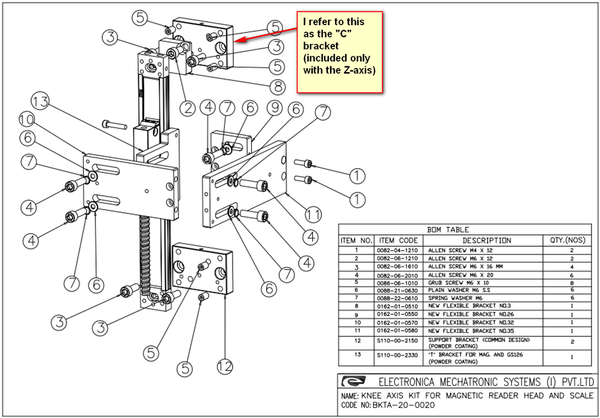

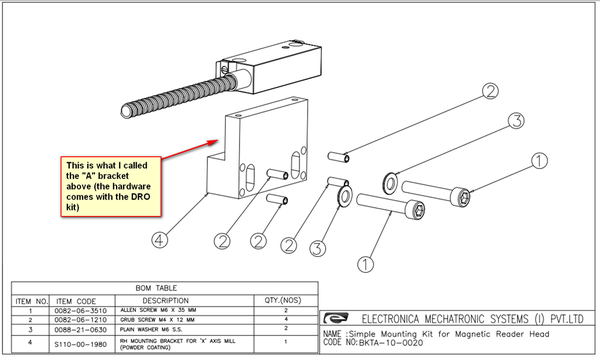

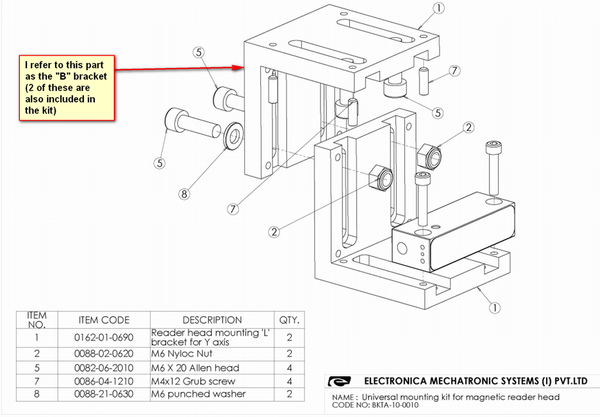

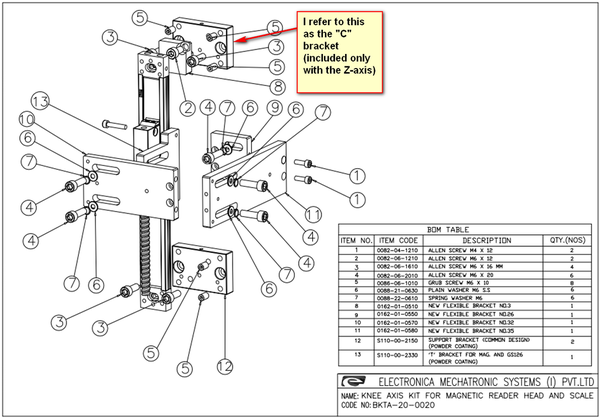

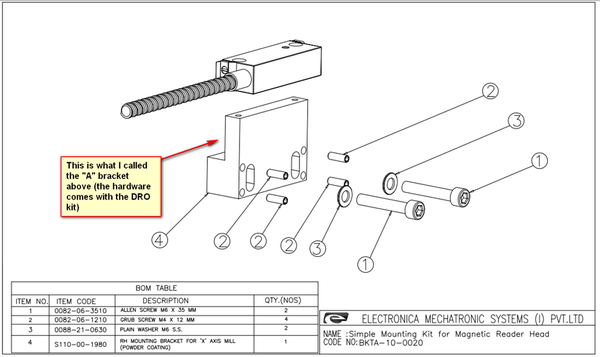

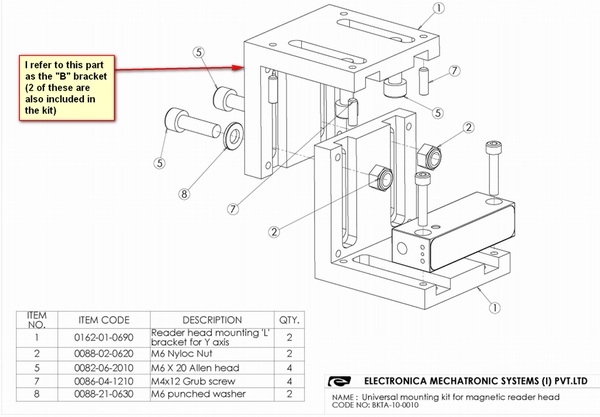

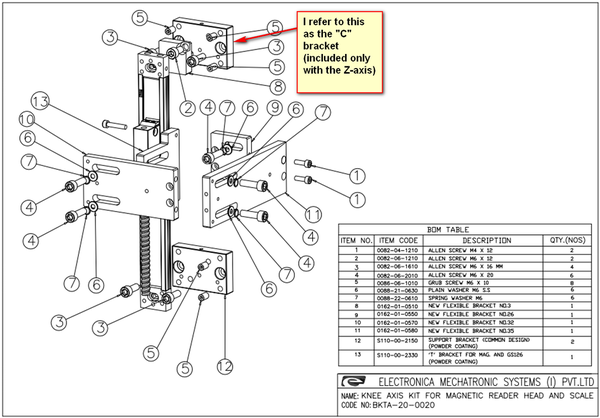

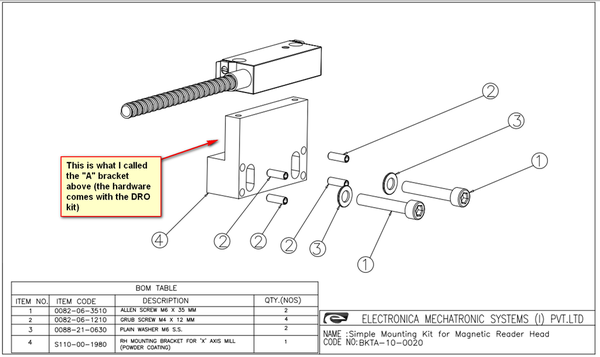

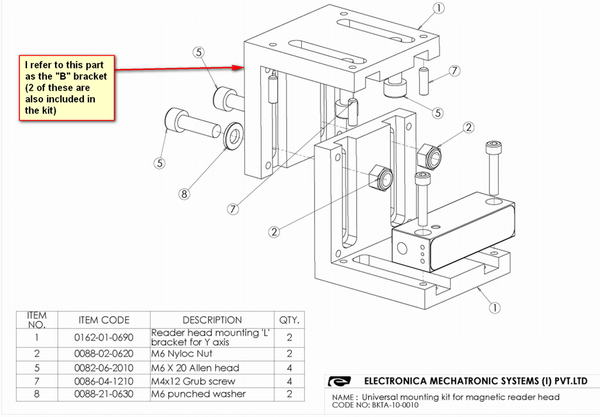

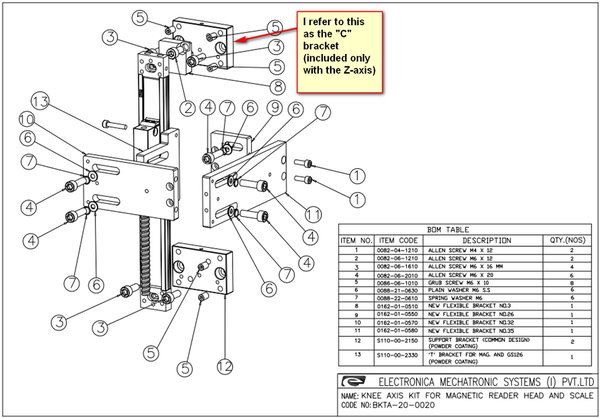

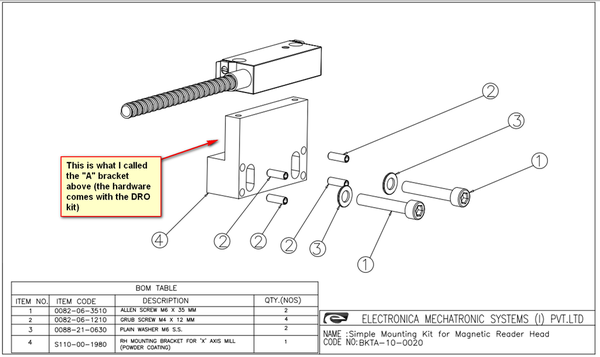

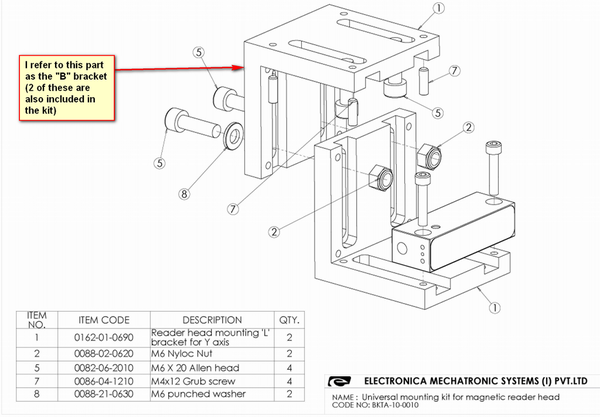

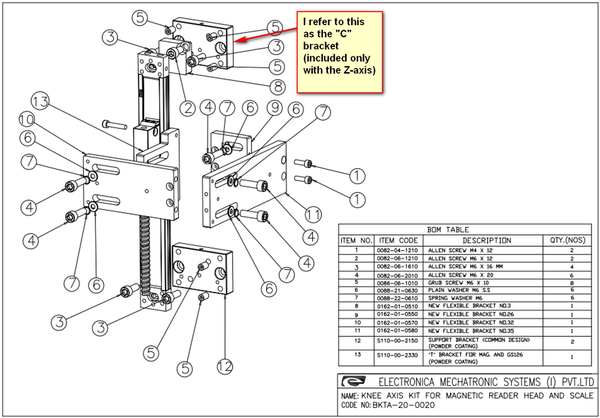

Ok, here is what I've done: First of, I received a bunch of different brackets / bolts as part of the kit and it took me some time to figure out how I can use them for my purposes. I ended up using modifying some of the brackets and not using others. Those parts that I used I labeled (for convenience) as brackets "A", "B" and "C"

The bracket "A had to be modified by shaving off a few mill from its top to fit over the rubber mat.

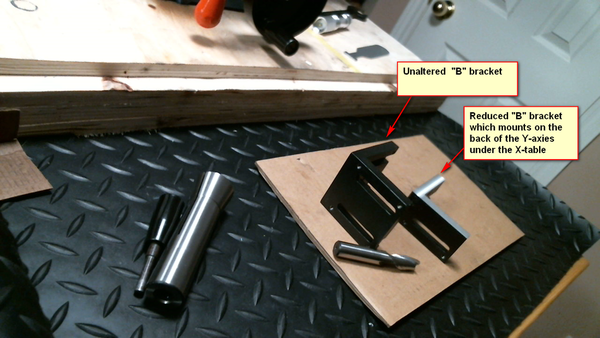

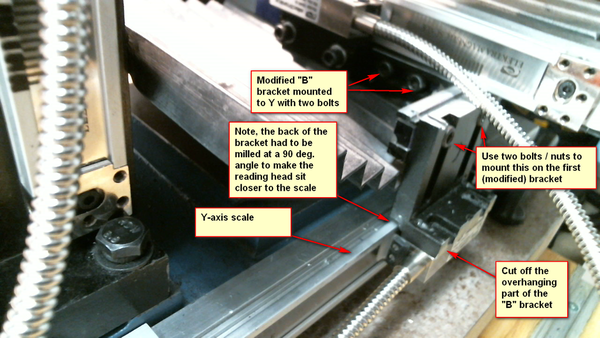

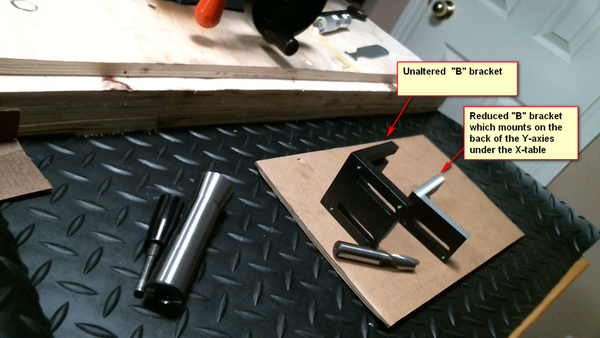

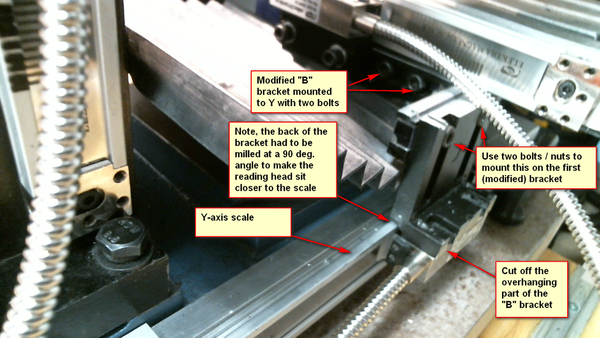

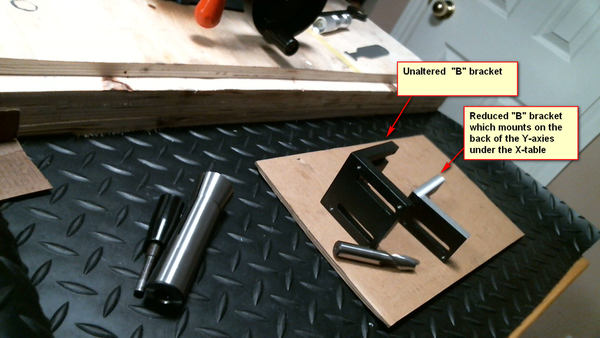

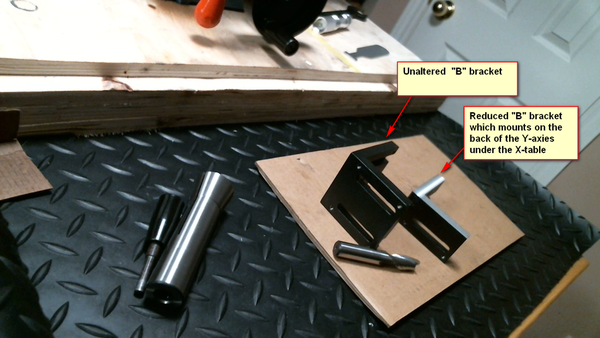

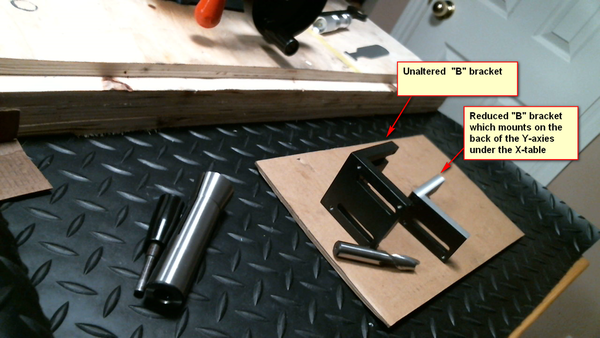

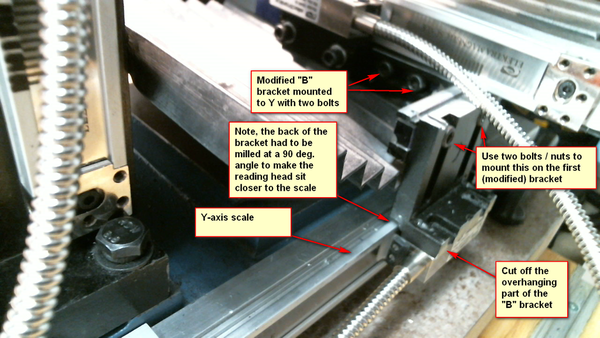

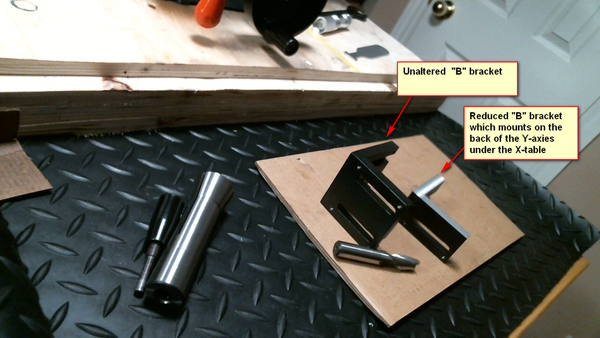

This pic shows both modified and unmodified "B" brackets

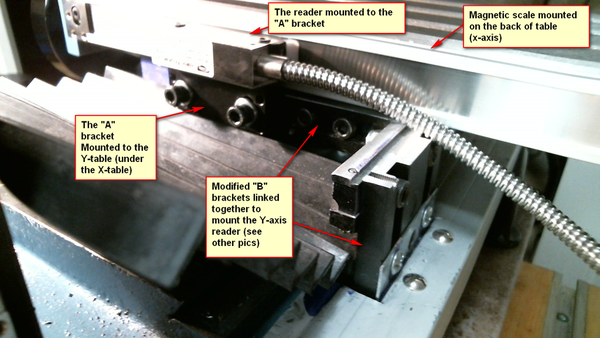

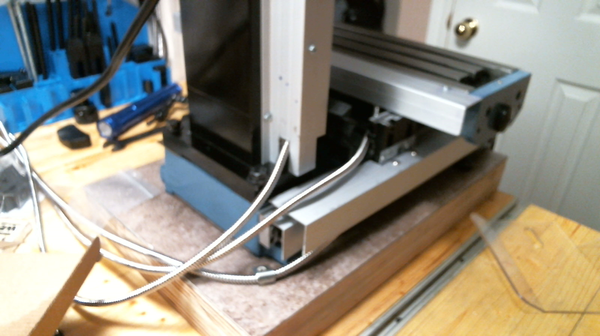

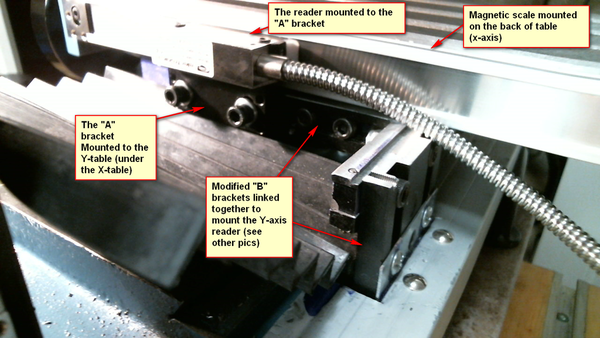

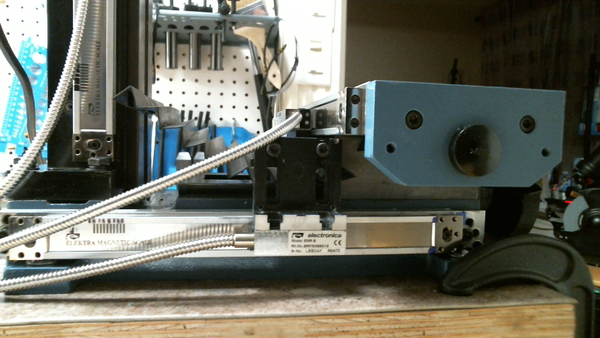

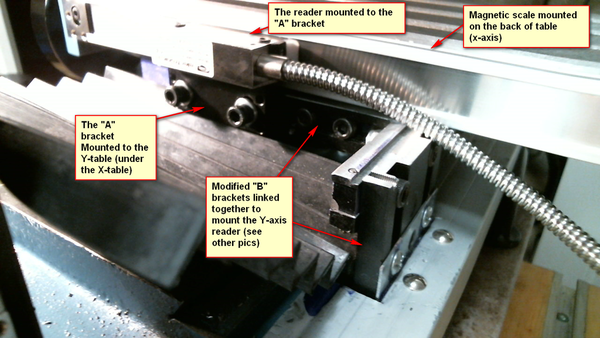

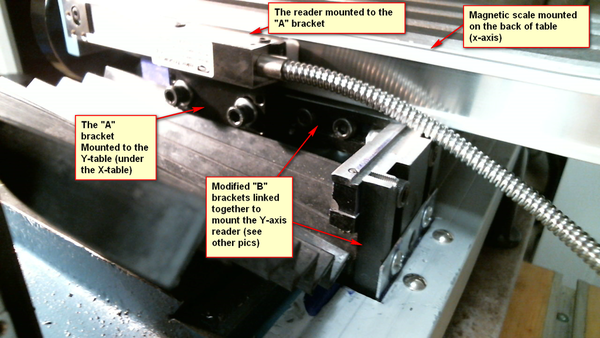

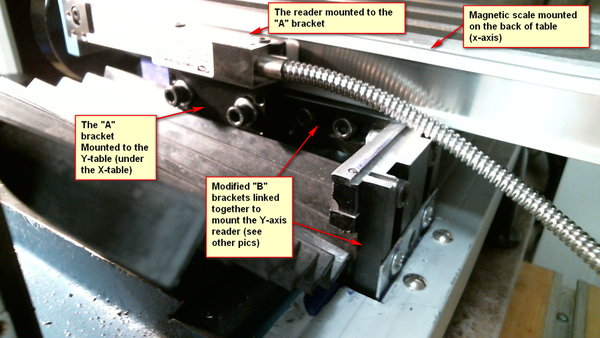

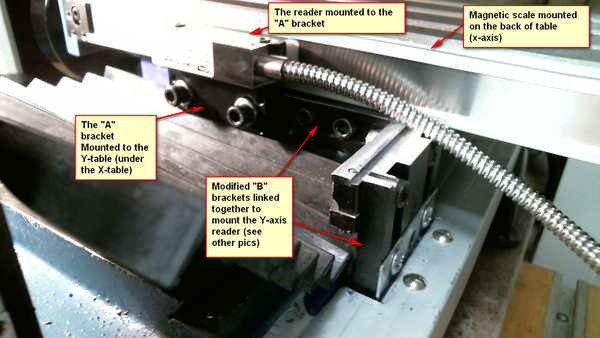

The following pic is somewhat out of place, but it hopefully explains how I used the brackets to mount the readers for X and Y axis:

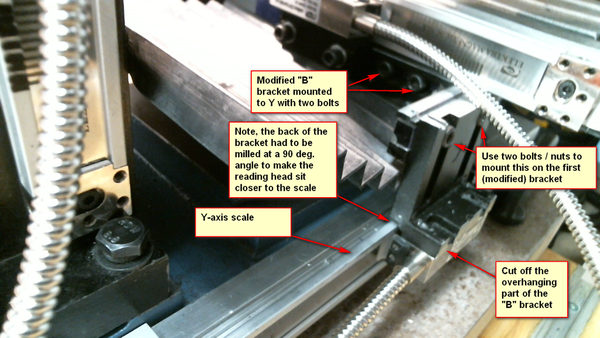

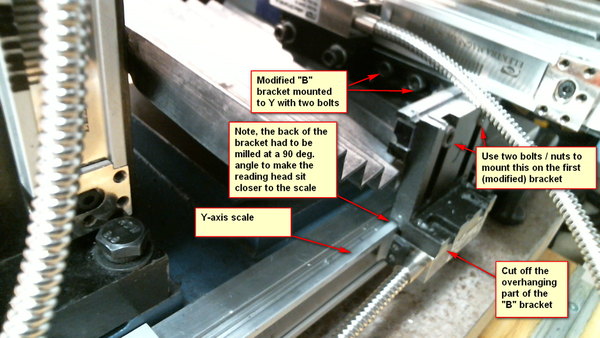

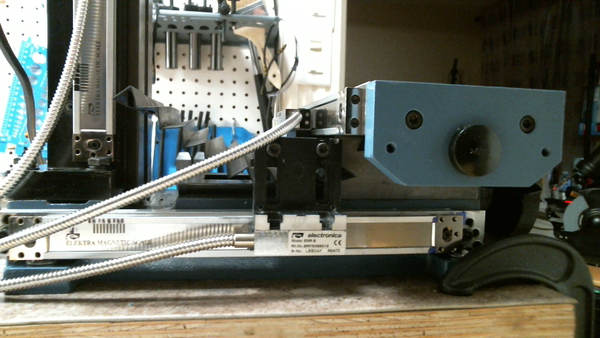

Here is a similar view with the Y covers removed so that you can see the mounting of the reader head:

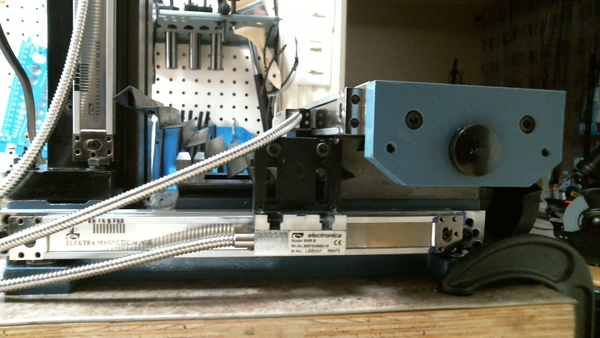

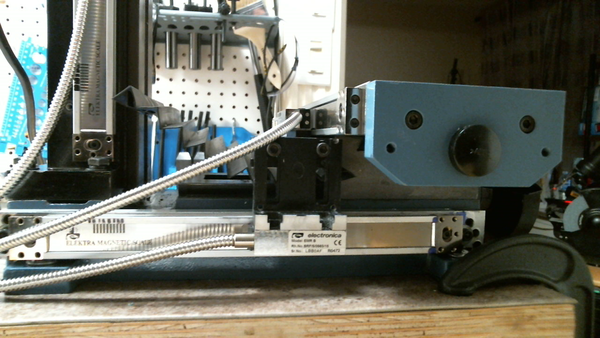

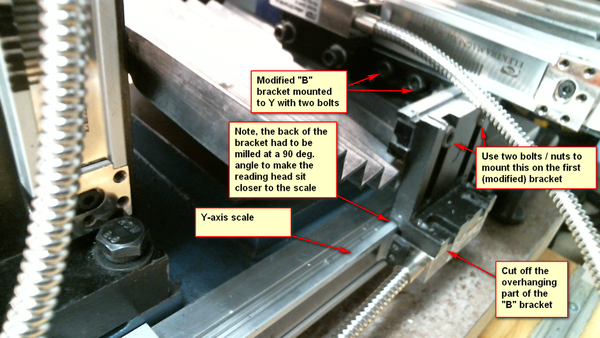

A better of view of the Y-axies:

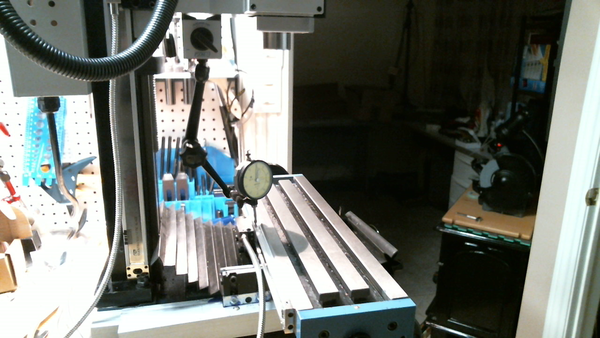

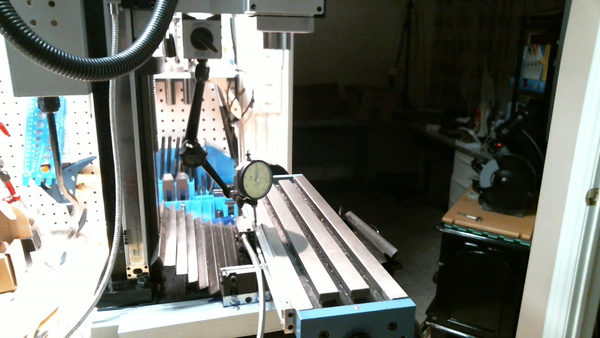

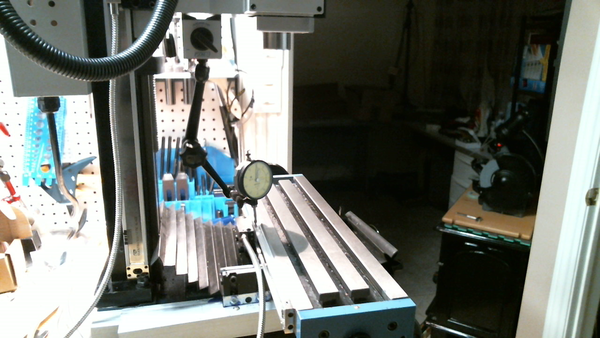

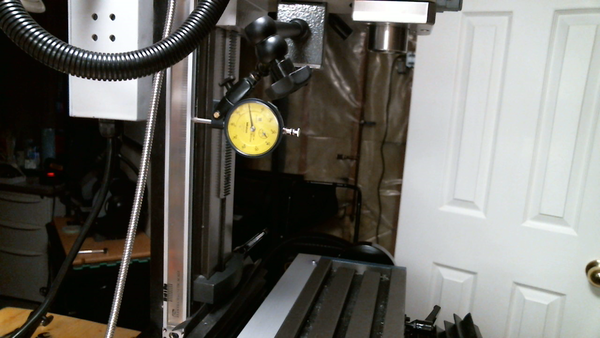

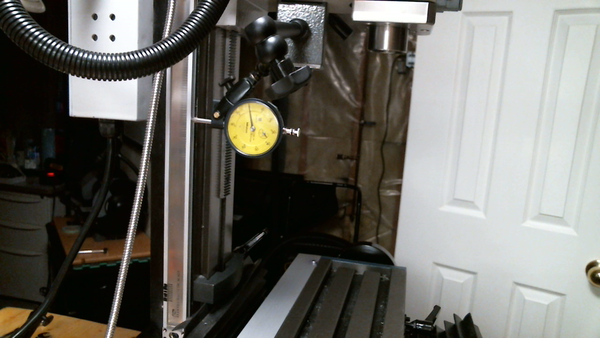

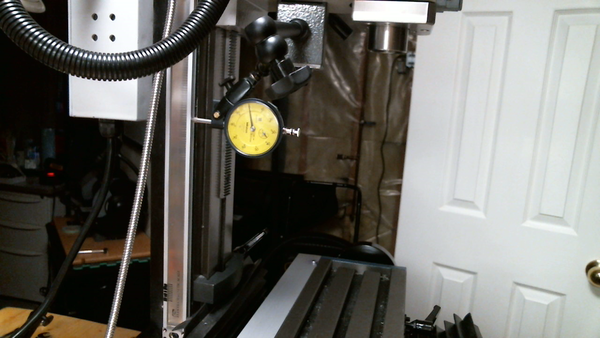

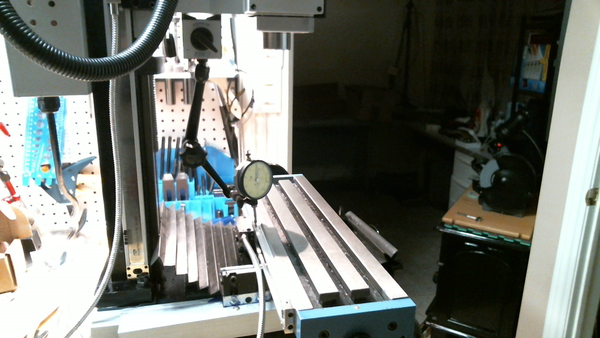

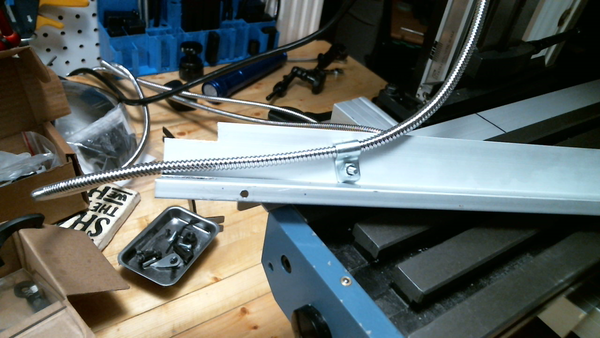

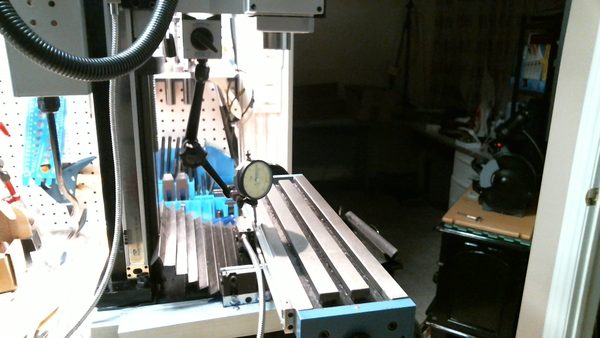

Making sure that X-axies scale is aligned with the table

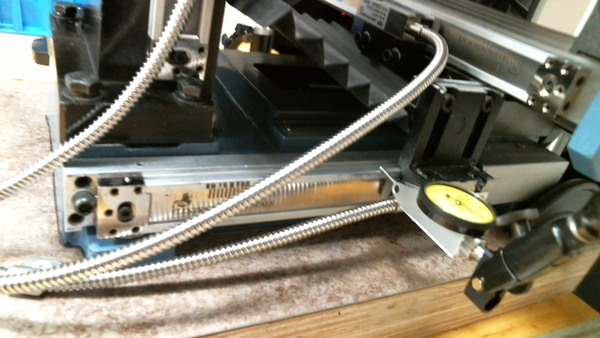

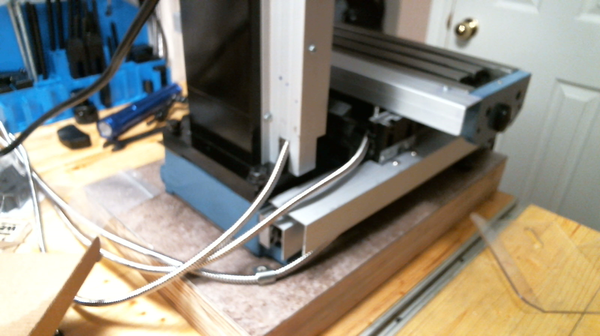

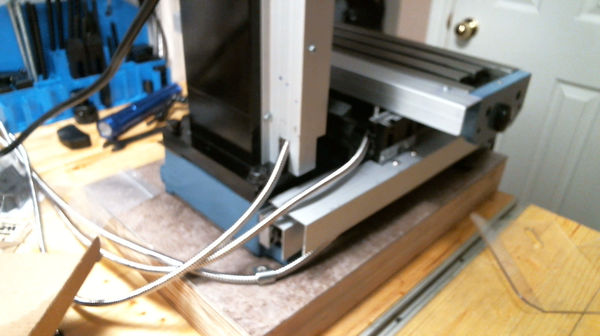

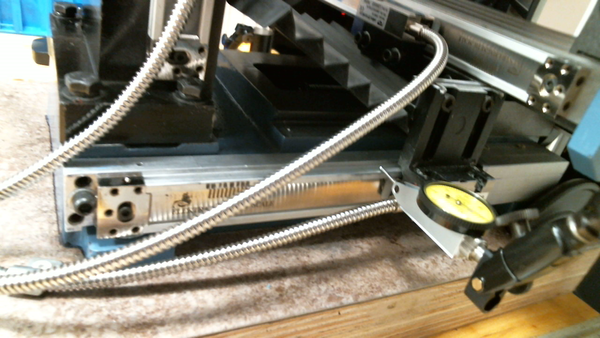

Making sure the Y-axies scale is aligned

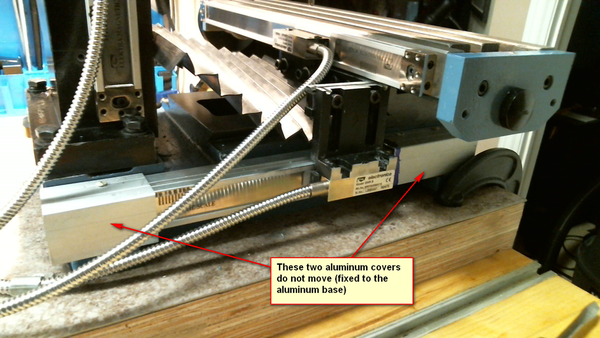

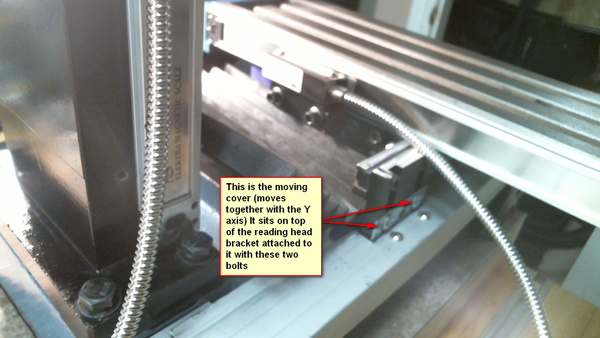

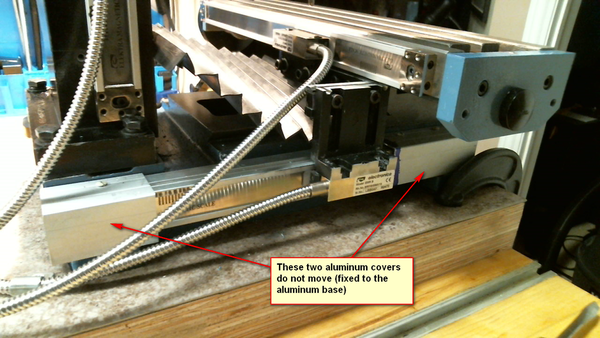

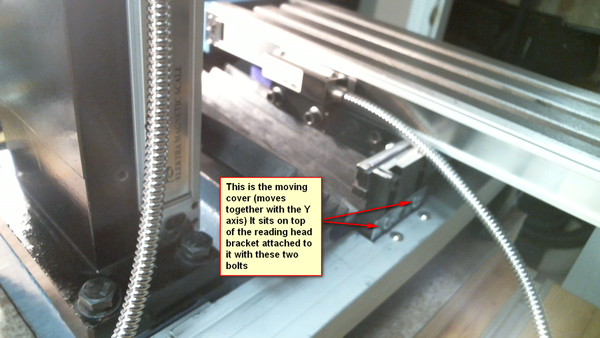

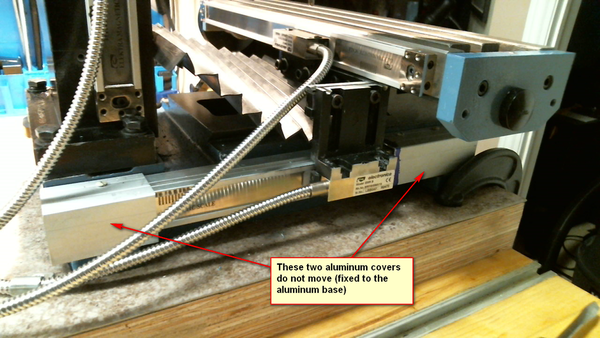

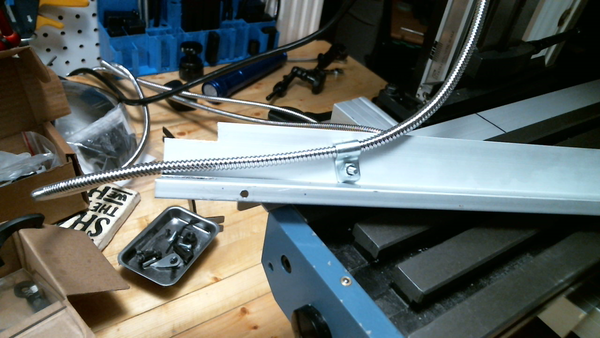

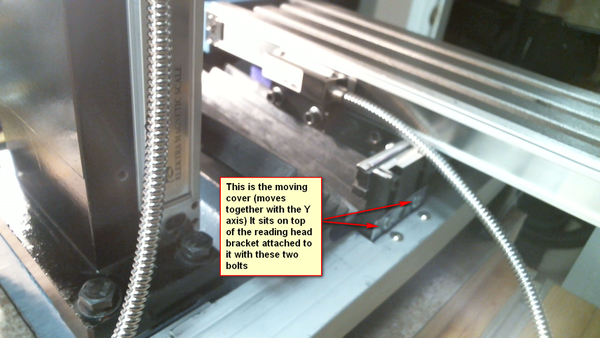

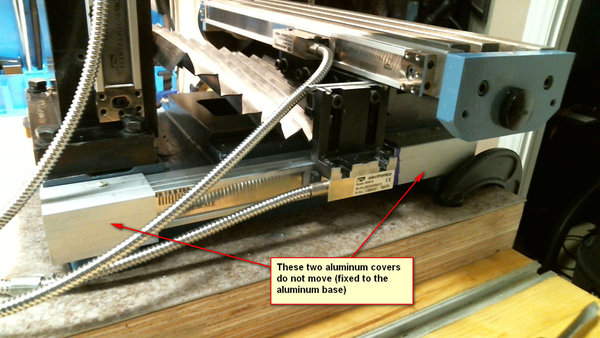

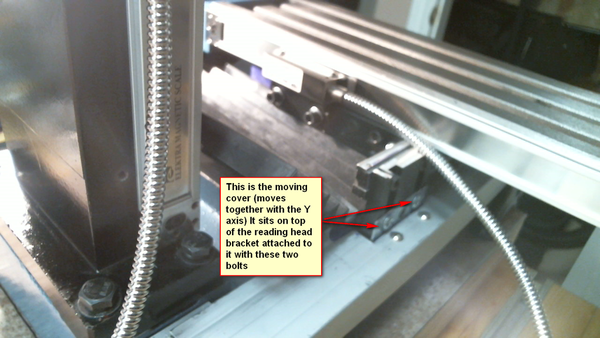

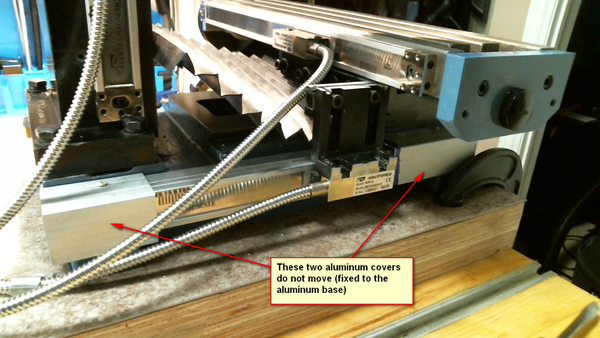

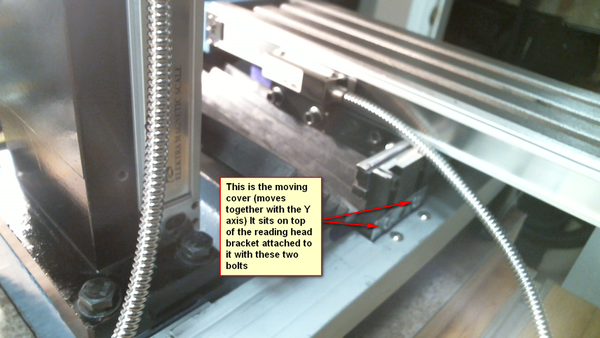

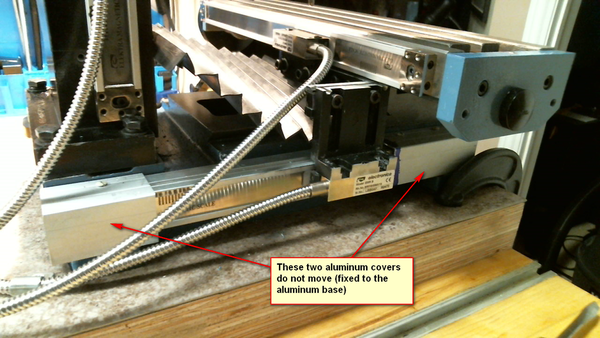

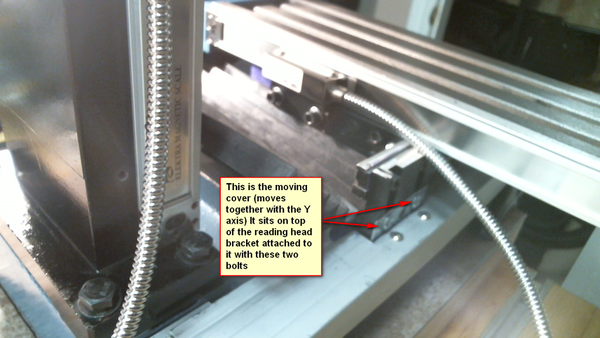

Now it is time to cover the Y-axies. I made the covers in three pieces: two short covers for the ends of the scale and one cover which would move together with the reading head (covering the head and the adjacent portions of the scale)

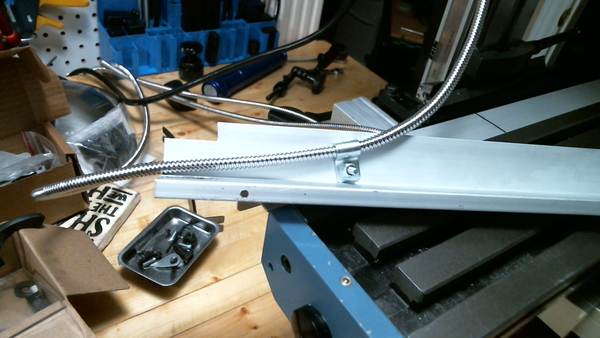

Here is the pics of the Z-axis

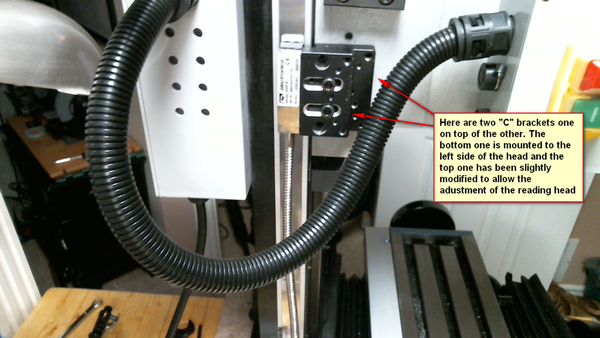

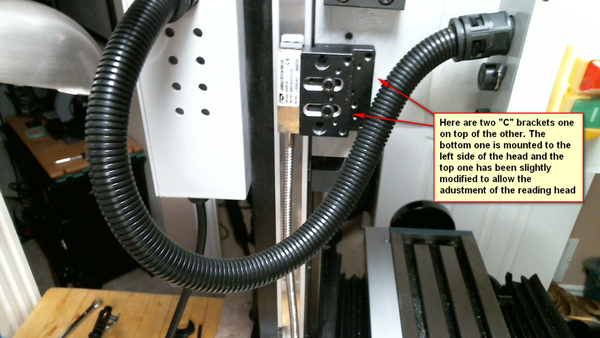

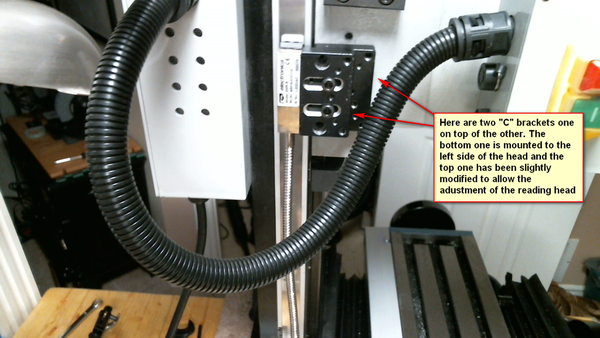

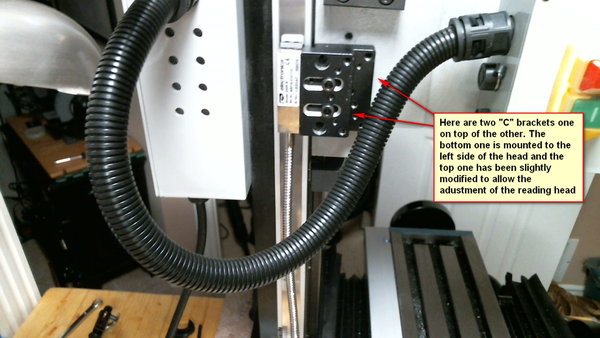

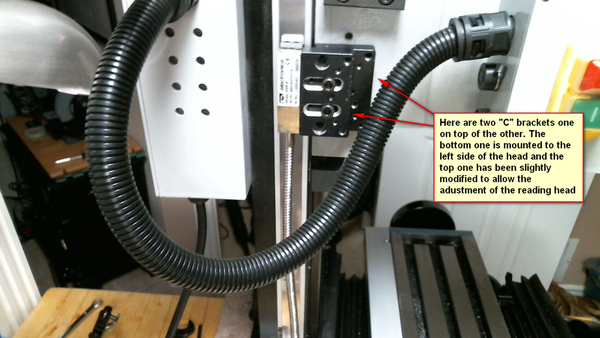

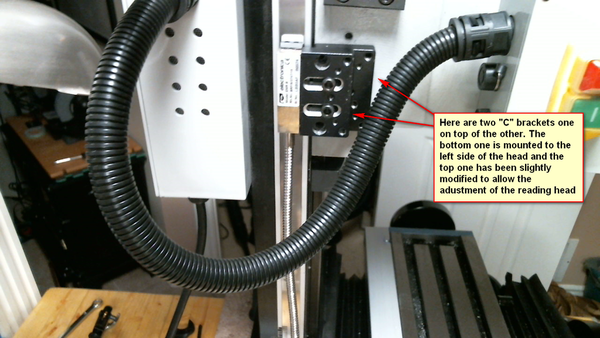

The scale mounts to the left side of the column (the fixed scale needs to be removed first) and then two "C" brackets are used to mount the reading head to the left side of the mill head.

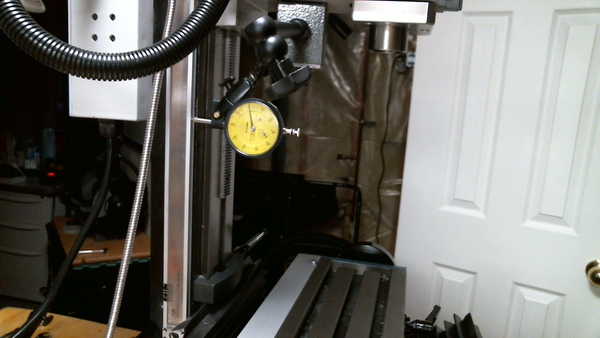

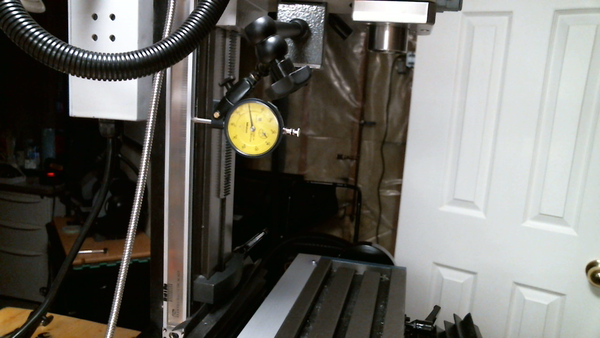

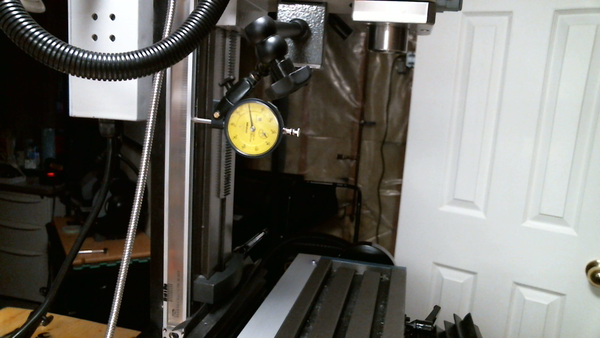

Making sure that Z scale is aligned

Wire slots are milled in the cover and a small wire management bracket (included in the hardware kit) installed on the inside of the z-scale's cover

This is the view from the back showing all covers installed

Regards,

Ed

A big thanks to Joe Pitz, his post and his youtube video http://www.hobby-machinist.com/threads/little-machine-shop-hitorque-mini-mill-dro-install.36143/

This led me into the right direction (especially with regards to the Y-axis needing a separate base with set screws to correct the taper in the cast iron). I implemented this part the same way as he suggested.

The differences in my config were due to the fact that I purchased a magnetic scales / readers option (while Joe's system is optical). This required somewhat different approach to mounting the rails, the reading heads and the covers. I have also chosen to mount both X and Y reader head mounting brackets at the back of the Y axis table to allow for an easier power feed installation, if I ever wanted to install one on the left side of the of x-axis table.

The finished product looks like this:

Ok, here is what I've done: First of, I received a bunch of different brackets / bolts as part of the kit and it took me some time to figure out how I can use them for my purposes. I ended up using modifying some of the brackets and not using others. Those parts that I used I labeled (for convenience) as brackets "A", "B" and "C"

The bracket "A had to be modified by shaving off a few mill from its top to fit over the rubber mat.

This pic shows both modified and unmodified "B" brackets

The following pic is somewhat out of place, but it hopefully explains how I used the brackets to mount the readers for X and Y axis:

Here is a similar view with the Y covers removed so that you can see the mounting of the reader head:

A better of view of the Y-axies:

Making sure that X-axies scale is aligned with the table

Making sure the Y-axies scale is aligned

Now it is time to cover the Y-axies. I made the covers in three pieces: two short covers for the ends of the scale and one cover which would move together with the reading head (covering the head and the adjacent portions of the scale)

Here is the pics of the Z-axis

The scale mounts to the left side of the column (the fixed scale needs to be removed first) and then two "C" brackets are used to mount the reading head to the left side of the mill head.

Making sure that Z scale is aligned

Wire slots are milled in the cover and a small wire management bracket (included in the hardware kit) installed on the inside of the z-scale's cover

This is the view from the back showing all covers installed

Regards,

Ed