- Joined

- Apr 12, 2013

- Messages

- 562

My eyes are really feeling the strain of reading the tiny dials, so being the electronic gadget guy I am I thought I would add a DRO to the cross slide. Mounting it looks challenging. I haven't seen any pics using the A11 milling cross slide either. So questions:

1) Does the backside of the DRO bar have to be mounted? I would have to really build a bracket way out to support it and still have full length use of the slide.

2) Any suggestions on brackets to attach to the saddle? The rounded curves may look nice but FLAT is easy to attach...

3) Is attaching the bar to the slide and the sensor to the saddle preferred?

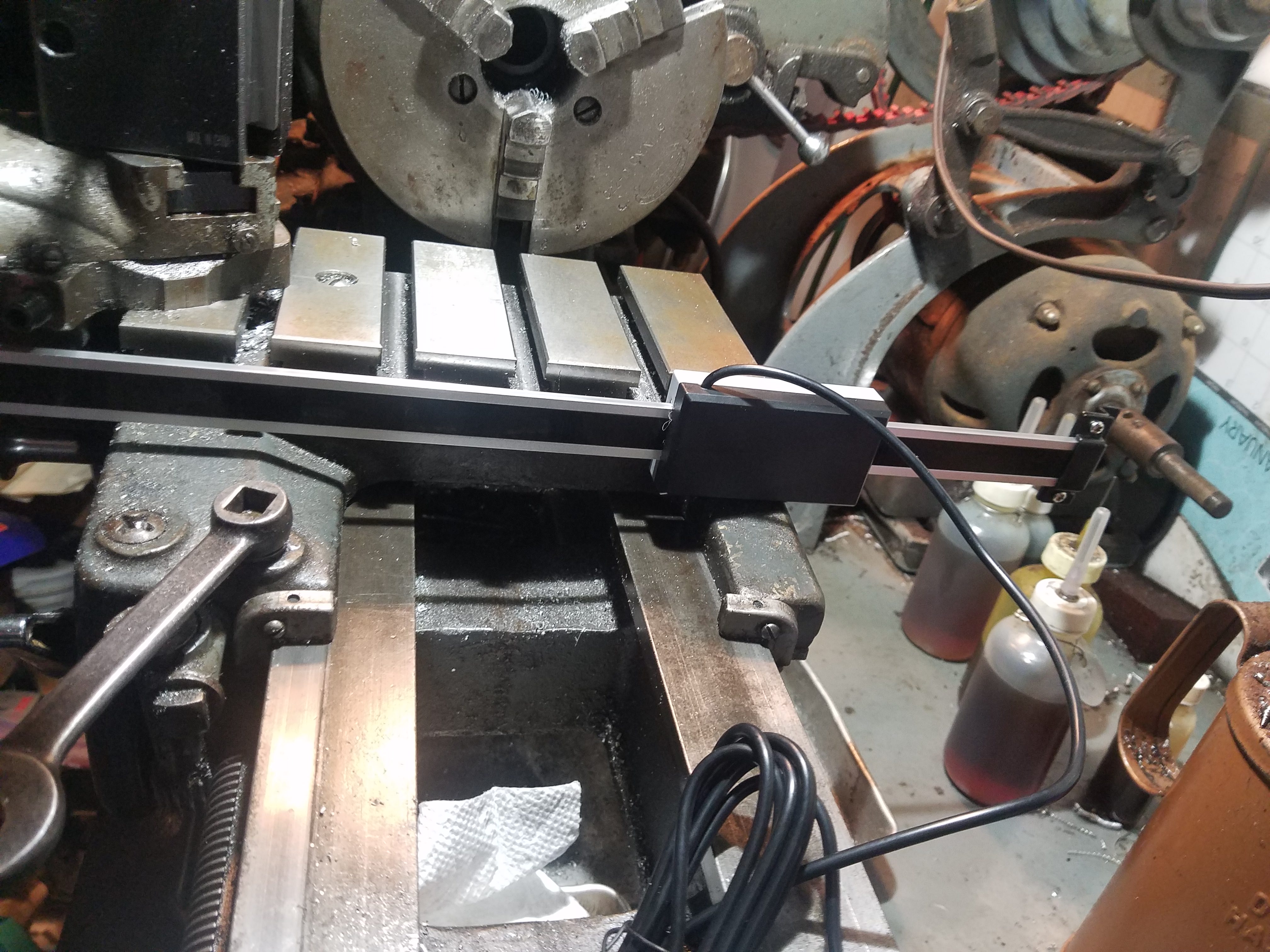

Fully advanced

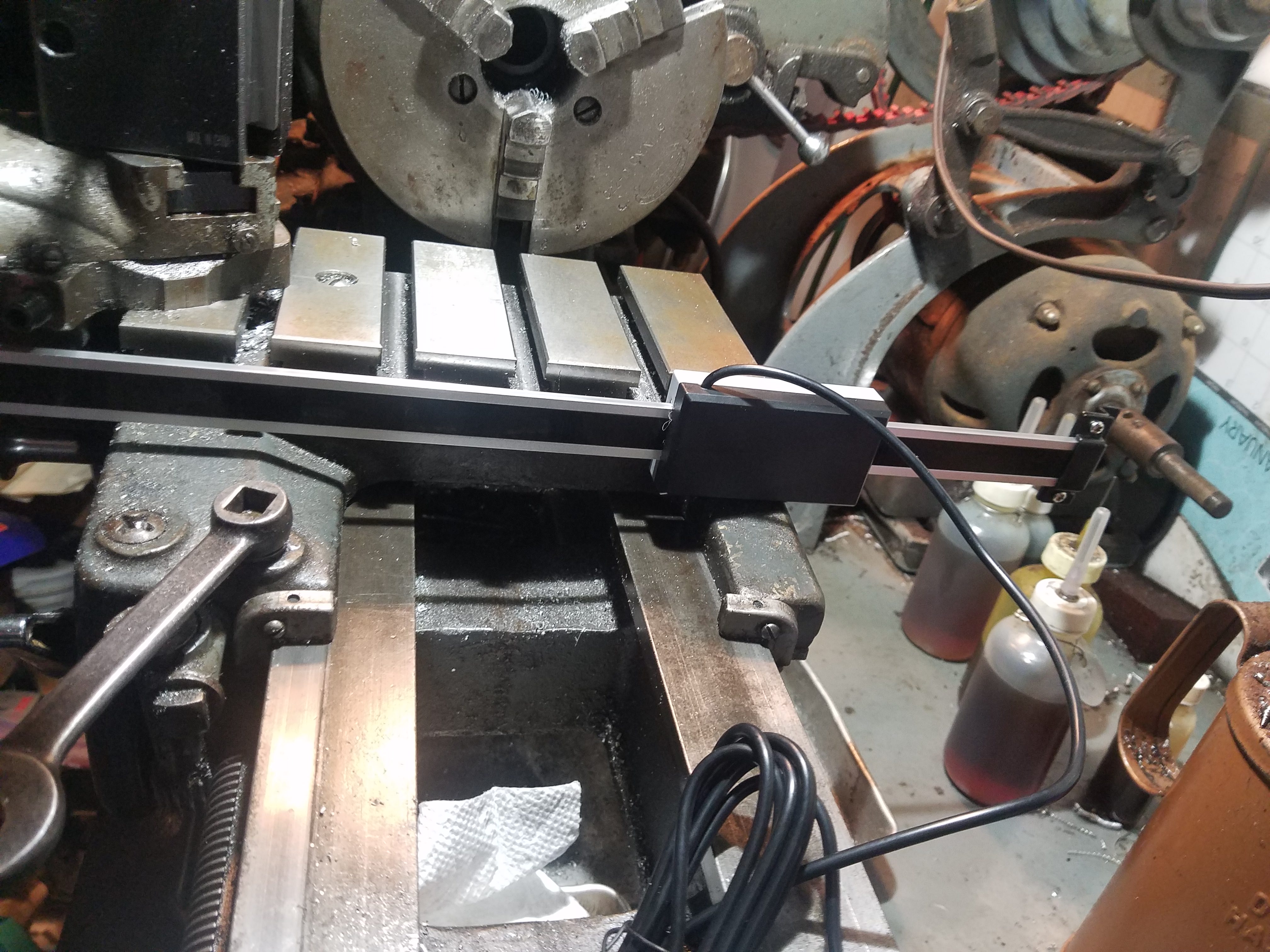

Fully retracted

1) Does the backside of the DRO bar have to be mounted? I would have to really build a bracket way out to support it and still have full length use of the slide.

2) Any suggestions on brackets to attach to the saddle? The rounded curves may look nice but FLAT is easy to attach...

3) Is attaching the bar to the slide and the sensor to the saddle preferred?

Fully advanced

Fully retracted