- Joined

- May 7, 2020

- Messages

- 263

Too many compressed air connections are just barely enough. At least that's how it feels in our shop with a combination of fixed and mobile equipment.

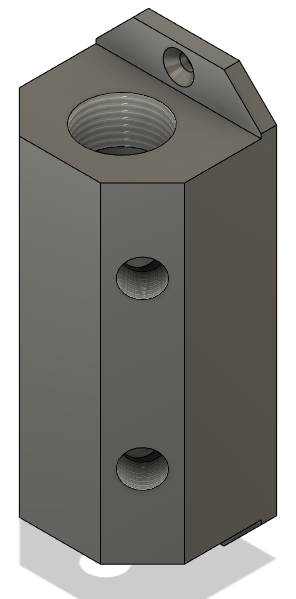

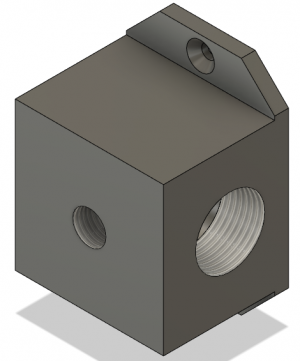

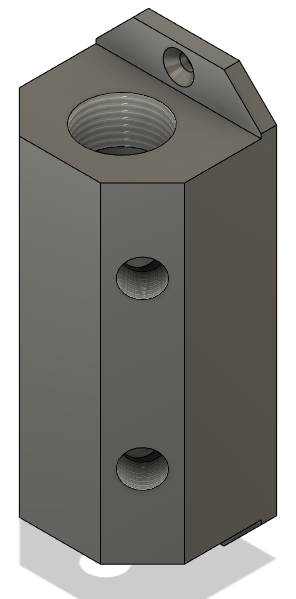

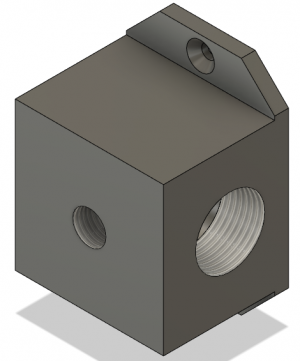

Didn't see anything we liked from the commercial vendors so we decided to make some air distribution manifolds. Wanted 4 outlets per drop, minimal strain on the air lines and a drain to catch any condensate. A nice jam session in Fusion 360 and we had a plan.

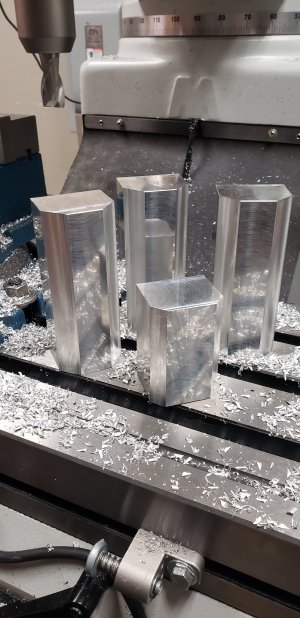

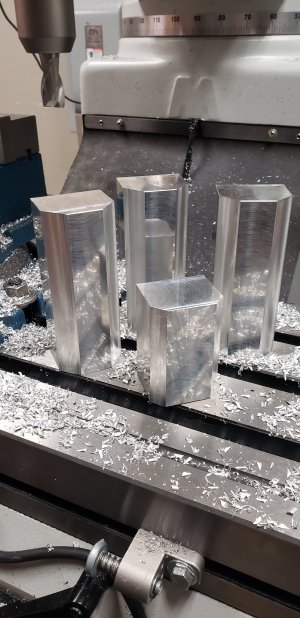

We had some 6061 laying around the shop and, looking closely, I could definitely see some manifolds inside. Time to square up some stock.

Gave us a chance to use our new Haas face mill in anger (Haas had an amazing sale last year).

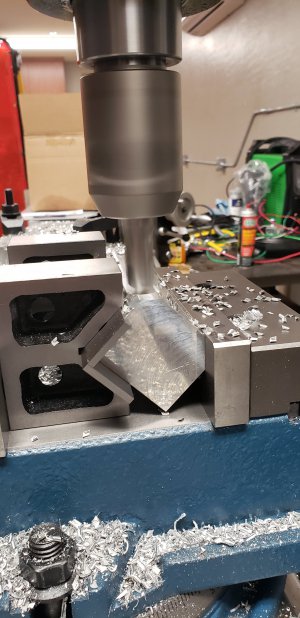

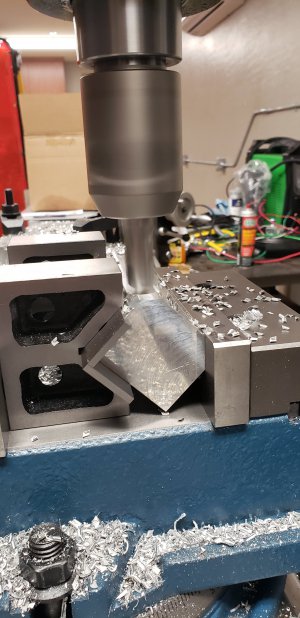

Time to do some big chamfering.

Setups presented some nice brain teasers - V-blocks with a little spacing was the ticket to get the right size chamfers for the 1/4 NPT fittings.

I might put this on our Christmas cards this year - love aluminum glitter. Outlines for three distribution manifolds and a pass-through that will feed our overhead hose reel.

We decided to use PEX as our primary air distribution solution. Because of the compressor after-cooler we'll never have hot air running through the lines. There will not be any degradation in the pressure rating related to heat. We also decided to use Shark-Bite fittings. Clean and easy. However, this solution requires NPT fittings. These manifolds will have a 3/4 NPT input and 1/4 NPT for the air connections.

We needed to make a central air channel. The 57/64 drill for 3/4 NPT threading would do double duty (this is the right size if you are reaming before tapping). 27/64 is the size for the 1/4 NPT.

The 3/4 NPT tapered reamer is BIG (.96" at the widest). Did not have a way to chuck this. But these NPT reamers/taps were all turned on centers and had index holes. A shop made 60 degree dead center chucked up on the spindle did the trick.

Without a chuck/spindle needed to use the manual down feed handle to apply the right pressure on the reamer while using the big-boy wrench to turn. The dead center keeps everything straight too. A little slow (and there were five 3/4 holes - not that fun). Worked great.

NPT threads are tapered and there is a depth you are trying to hit (rule of thumb is 3 1/2 turns hand tight for the male fitting). To do that you need to tap the hole to a specific depth (and it isn't all the way to the end). Same goes for the reamer. For both of my 3/4 and 1/4 taps, the right depth was 7 troughs still showing above the work piece. Pro tip: I used a little dental instrument to count the threads - easier on the eyes.

After tapping all 21 holes we did a finishing touch

Added another chamfer (first time using an angle block). A little tricky - centered a 3/4 end mill on the mounting tab so all the pressure was at a right angle to the vise jaws (the other way would likely have ripped the work piece out of the vise - geometry is better than friction).

Finished part and installation. Happy with the way this turned out. Fun and very educational project. Really got to practice re-using setups and "production line" techniques.

Didn't see anything we liked from the commercial vendors so we decided to make some air distribution manifolds. Wanted 4 outlets per drop, minimal strain on the air lines and a drain to catch any condensate. A nice jam session in Fusion 360 and we had a plan.

We had some 6061 laying around the shop and, looking closely, I could definitely see some manifolds inside. Time to square up some stock.

Gave us a chance to use our new Haas face mill in anger (Haas had an amazing sale last year).

Time to do some big chamfering.

Setups presented some nice brain teasers - V-blocks with a little spacing was the ticket to get the right size chamfers for the 1/4 NPT fittings.

I might put this on our Christmas cards this year - love aluminum glitter. Outlines for three distribution manifolds and a pass-through that will feed our overhead hose reel.

We decided to use PEX as our primary air distribution solution. Because of the compressor after-cooler we'll never have hot air running through the lines. There will not be any degradation in the pressure rating related to heat. We also decided to use Shark-Bite fittings. Clean and easy. However, this solution requires NPT fittings. These manifolds will have a 3/4 NPT input and 1/4 NPT for the air connections.

We needed to make a central air channel. The 57/64 drill for 3/4 NPT threading would do double duty (this is the right size if you are reaming before tapping). 27/64 is the size for the 1/4 NPT.

The 3/4 NPT tapered reamer is BIG (.96" at the widest). Did not have a way to chuck this. But these NPT reamers/taps were all turned on centers and had index holes. A shop made 60 degree dead center chucked up on the spindle did the trick.

Without a chuck/spindle needed to use the manual down feed handle to apply the right pressure on the reamer while using the big-boy wrench to turn. The dead center keeps everything straight too. A little slow (and there were five 3/4 holes - not that fun). Worked great.

NPT threads are tapered and there is a depth you are trying to hit (rule of thumb is 3 1/2 turns hand tight for the male fitting). To do that you need to tap the hole to a specific depth (and it isn't all the way to the end). Same goes for the reamer. For both of my 3/4 and 1/4 taps, the right depth was 7 troughs still showing above the work piece. Pro tip: I used a little dental instrument to count the threads - easier on the eyes.

After tapping all 21 holes we did a finishing touch

Added another chamfer (first time using an angle block). A little tricky - centered a 3/4 end mill on the mounting tab so all the pressure was at a right angle to the vise jaws (the other way would likely have ripped the work piece out of the vise - geometry is better than friction).

Finished part and installation. Happy with the way this turned out. Fun and very educational project. Really got to practice re-using setups and "production line" techniques.

Last edited: