- Joined

- Apr 26, 2018

- Messages

- 34

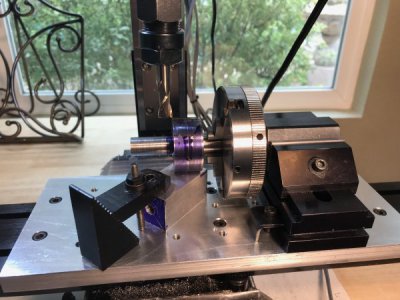

I am trying to make a single piston dual web crankshaft for a miniature steam engine. I first tried to make it with separate parts and press fit shafts into the web with spring pins to secure the shafts. I had trouble getting the center shafts to be aligned perpendicular to the web's.

So now I am thinking of making the 1/4 in shaft and web from the same steel round rod 1 1/2 in dia. and then just pin the two webs together with a 1/4 in shaft and contained with 1/16 in spring pins. It seems to me that this is easy to do on the lathe and I only have to make sure the two webs are parallel with a block of the correct size.

Does this make sense?

So now I am thinking of making the 1/4 in shaft and web from the same steel round rod 1 1/2 in dia. and then just pin the two webs together with a 1/4 in shaft and contained with 1/16 in spring pins. It seems to me that this is easy to do on the lathe and I only have to make sure the two webs are parallel with a block of the correct size.

Does this make sense?