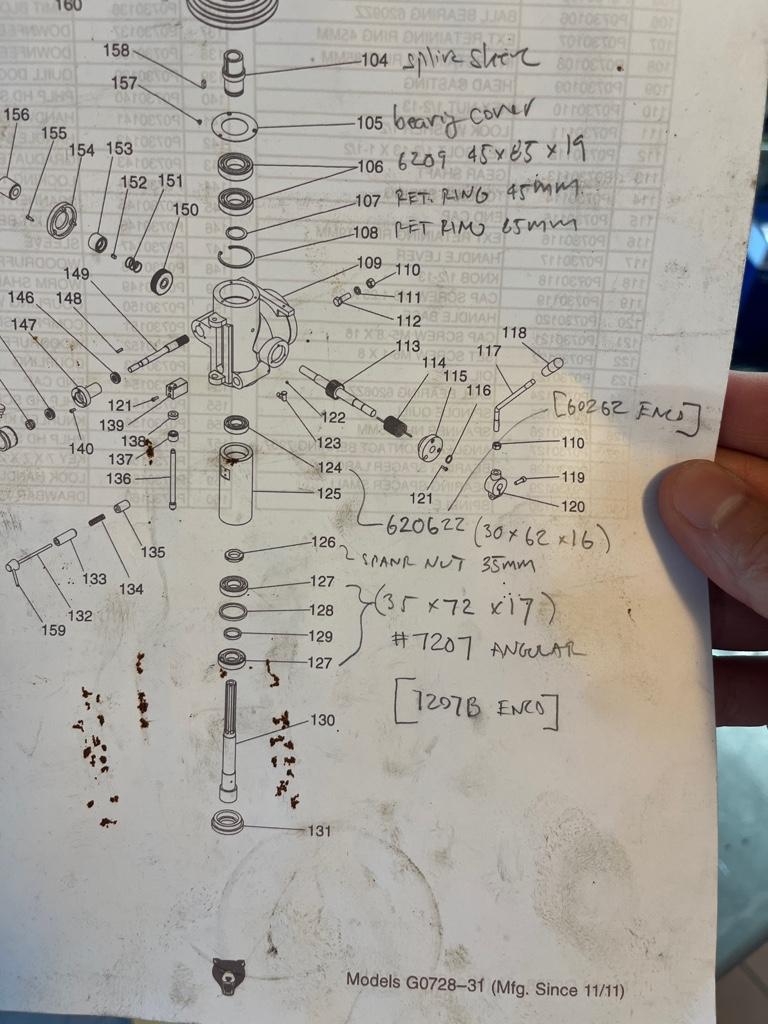

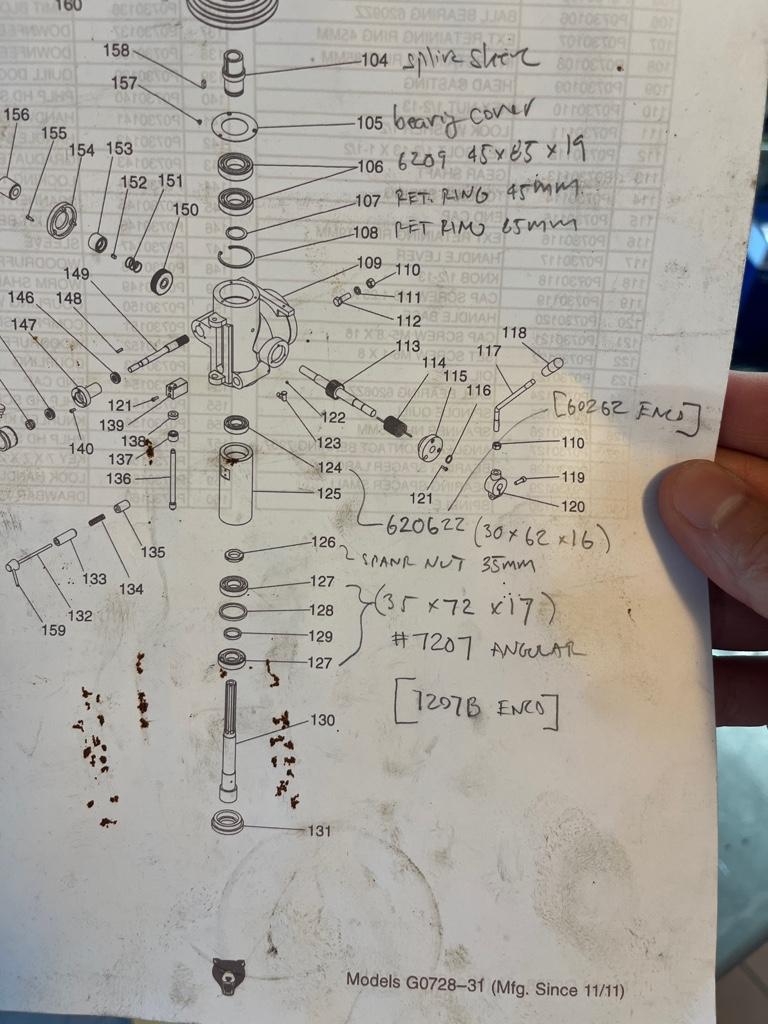

The nut on the grizzly had a set screw to retain it. The nut in the Bridgeport video has a bent tablock washer to retain it. The grizzly has neither. I have seen some spanner nuts sold with a self locking design. The grizzly genuine replacement part is seriously back ordered and I do not know if it is self locking or not. Would you all expect there to be some means of locking this nut? Thoughts that come to mind Are a second thin lock nut or a drop of low strength thread locker