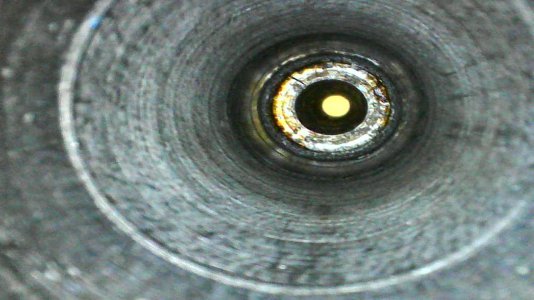

Not familiar with what exact pattern this mill is, and shots are too narrow to ID it.........but R8 needs the spindle up to access drawbar. R8 appears in bench top mill drills, the 3/4 size Rockwells & Clausings, of course standard 12" knee Bridgeport pattern, and the larger version 16" knee. And not much else.

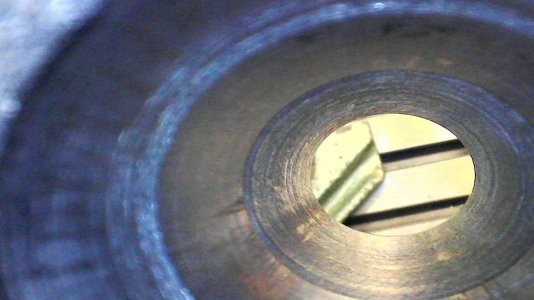

Flats on the spindle nose mean something different. Morse or Brown & Sharpe for milling, a drawbar insures against the cutter helix pulling the sleeve out. Hard for me to envision a knockout 100% reliable milling; drilling naturally is world standard, using the tang as the drive connection.

While a zillion machines had B&S taper, they were horizontals. It was unsuitable for compact designs [ie Bridgeport spindle is restricted by knee] as it is just silly long. Great alignment and drive transmission but not very forward thinking.

Morse, B&S and some others are known as self holding tapers, compared to self releasing like 30, 40 or 50 NMTB [aka NM], or CAT. They need drive lugs on spindle to engage notches on holder. The shape means easy withdrawal, even tilting to avoid obstructions. CAT wouldn't exist without such a feature.

BTW, NM and CAT are almost interchangeable; some CAT are threaded smaller for retention knobs, not matching drawbars, others are.