-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

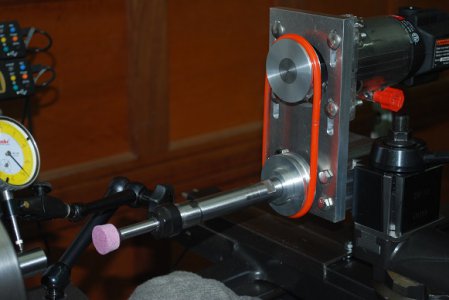

Dumore Tool Post grinder

- Thread starter tmenyc

- Start date

- Joined

- Jan 31, 2016

- Messages

- 11,423

A bit of safety advise ........don't stand or sit in front of the quill when running . I've had wheels disintegrate in the past on internal grinders . They go along was FAST ! Also , keep that smaller wheel dressed .

- Joined

- Jul 2, 2014

- Messages

- 7,594

Not correct, Duane. Grinding wheel grit grains get dull, they wear down, and the spaces between them get full of swarf. The wheels must be dressed to keep them cutting properly, and to keep the desired shape on the wheel face.I thought I heard once that you do not dress internal wheels, did I hear correctly?

Doesn't make sense but....

- Joined

- Nov 9, 2015

- Messages

- 406

Agree, and in some circumstances it makes sense to grind a relief behind a mounted point's leading edge, for example when grinding chuck jaws.Not correct, Duane. Grinding wheel grit grains get dull, they wear down, and the spaces between them get full of swarf. The wheels must be dressed to keep them cutting properly, and to keep the desired shape on the wheel face.

- Joined

- Nov 9, 2015

- Messages

- 406

- Joined

- Jan 31, 2016

- Messages

- 11,423

All above are true . Your internal wheels load up just like your external wheels . ( especially if they are not relieved on the back side ) They will build up pressure while grinding and break down on you when you least want it to ! All of our grinders had flood coolant and this still occurred . Heat is your worst enemy in the grinding process . That wheel wants to bite into your part . Keep your wheels dressed and undercut the rear for best results . Diamond and Borazon wheels don't need dressing , they are used for specialty jobs such as chrome .

I have a little Precise grinder and a smaller Dotco that wind out at 80,000 rpm . It's interesting when the wheels break down !

I prefer to use Norbide sticks for dressing over mounted diamonds also . Those smaller wheels sometimes grab the diamond and that's where the fun really begins !

I have a little Precise grinder and a smaller Dotco that wind out at 80,000 rpm . It's interesting when the wheels break down !

I prefer to use Norbide sticks for dressing over mounted diamonds also . Those smaller wheels sometimes grab the diamond and that's where the fun really begins !