- Joined

- Jan 16, 2016

- Messages

- 302

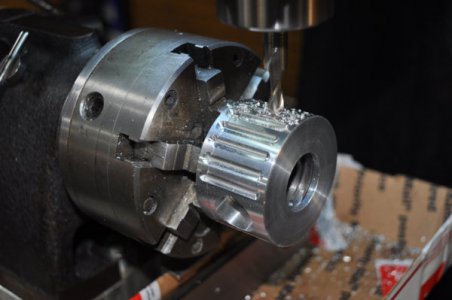

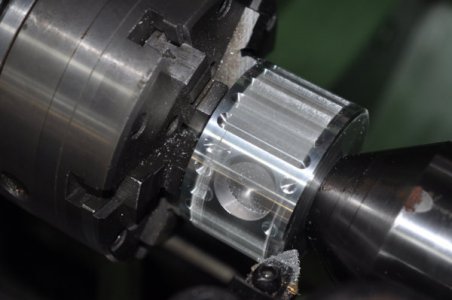

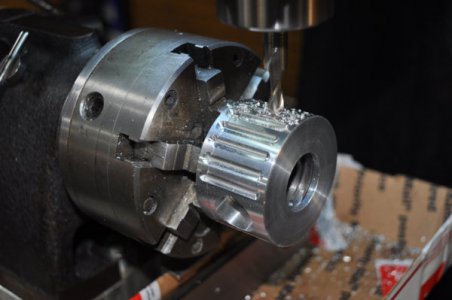

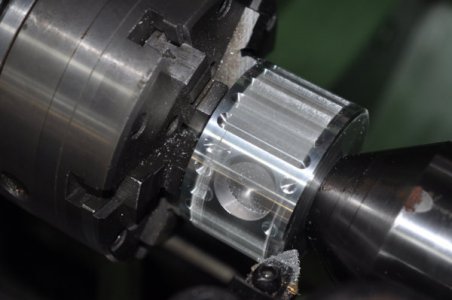

A FRIEND WHO OUTFITS PEOPLE FOR PROSTHETIC LIMBS HAS SOME SPECIALIZED EQUIPMENT .

ONE OF THE TOOLS HE USES IS A SUPPORT THAT ALLOWS HIS PATIENTS TO STAND ON ONE LEG

WHILE HE WORKS ON THE OTHER .

THIS HAS A NARROW BICYCLE SEAT MOUNTED ON A STAND . IT NEEDS TO BE HEIGHT ADJUSTABLE

FOR DIFFERENT SIZE PEOPLE .SO IT HAS A 1" ACME THREADED SHAFT .

THE PROFESSIONALLY AVAILABLE DEVICE THEY SOLD HIM HAD A NUT WITH WINGS ,

THIS WAS NICELY MADE BUT REQUIRED HIM TO SPIN IT UP AN DOWN THE SHAFT

WHILE THE WINGS WOULD HIT THE PATIENT's LEGS .

MY TAKE ON THIS WAS TO MAKE A LARGE SIDE EDUCATED NUT LIKE WE USE FOR A QUILL STOP

ON OUR MILLING MACHINES .

HE GAVE ME THE NUT AND SHAFT TO PLAY WITH AND THIS IS WHAT I CAME UP WITH .

PRESS THE BUTTON AND THE THREADS DISENGAGE . THE KNURLS MAKE IT EASY TO

FINE ADJUST UNDER A LOAD . I ALSO HAVE A THRUST BEARING UNDER IT .

SO HERE GOES , HE WILL BE TAKING IT TO THE LEG SHOP TOMORROW FOR A TEST DRIVE .

ONE OF THE TOOLS HE USES IS A SUPPORT THAT ALLOWS HIS PATIENTS TO STAND ON ONE LEG

WHILE HE WORKS ON THE OTHER .

THIS HAS A NARROW BICYCLE SEAT MOUNTED ON A STAND . IT NEEDS TO BE HEIGHT ADJUSTABLE

FOR DIFFERENT SIZE PEOPLE .SO IT HAS A 1" ACME THREADED SHAFT .

THE PROFESSIONALLY AVAILABLE DEVICE THEY SOLD HIM HAD A NUT WITH WINGS ,

THIS WAS NICELY MADE BUT REQUIRED HIM TO SPIN IT UP AN DOWN THE SHAFT

WHILE THE WINGS WOULD HIT THE PATIENT's LEGS .

MY TAKE ON THIS WAS TO MAKE A LARGE SIDE EDUCATED NUT LIKE WE USE FOR A QUILL STOP

ON OUR MILLING MACHINES .

HE GAVE ME THE NUT AND SHAFT TO PLAY WITH AND THIS IS WHAT I CAME UP WITH .

PRESS THE BUTTON AND THE THREADS DISENGAGE . THE KNURLS MAKE IT EASY TO

FINE ADJUST UNDER A LOAD . I ALSO HAVE A THRUST BEARING UNDER IT .

SO HERE GOES , HE WILL BE TAKING IT TO THE LEG SHOP TOMORROW FOR A TEST DRIVE .