- Joined

- Jan 7, 2016

- Messages

- 3,257

Wow. That is incredible. Do you have a build thread somewhere; maybe on another site? Would love to know more but don't want to derail Jeff's thread.Hi bring

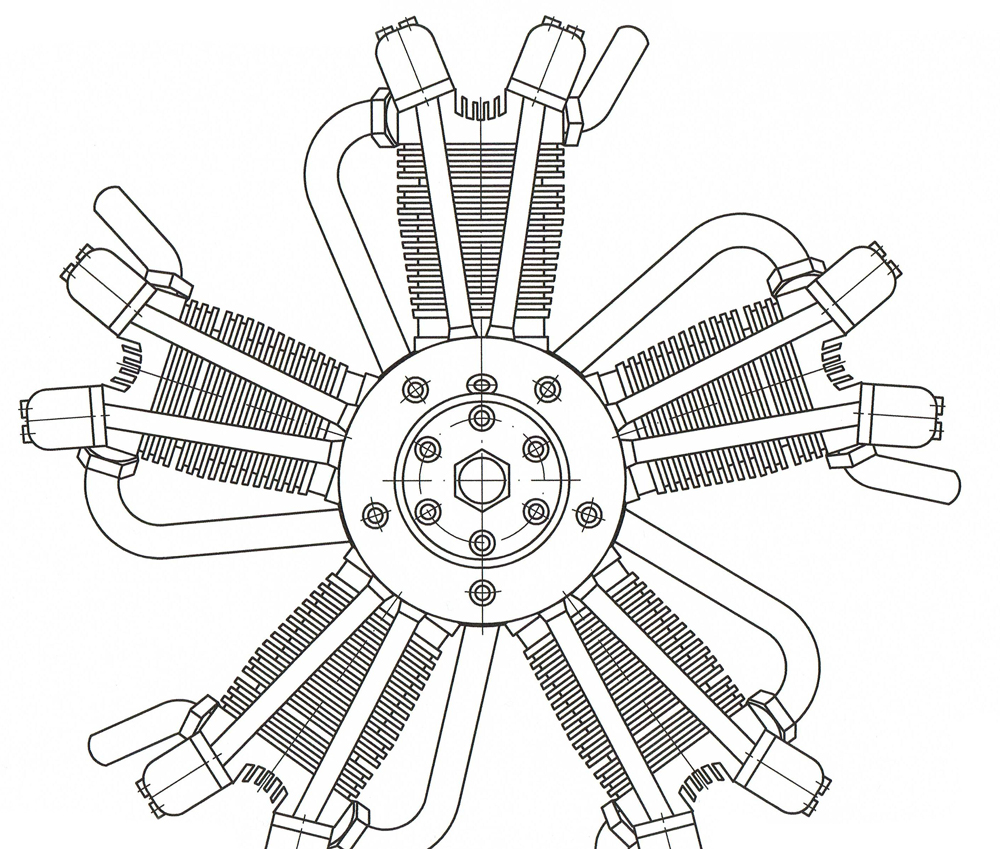

As requested a few photos of the traction engine I am building. Its a Minnie 1 inch scale by L C Mason. Been a lot of work and due to all the lockouts we have had i have getting on with it.

Regards

Myford10