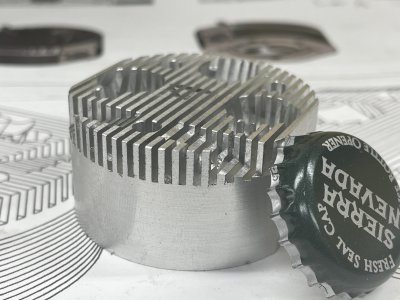

Well, I'm working on the heads and broke a 4-40 tap. This is reminiscent of one of my very first posts on this thread re: the crankcase.

It was a carless mistake that shouldn't have happened. I was in a rush trying to finish up tapping the thread before heading upstairs for dinner. I've already learned that lesson more than once before. Oh well.

Unfortunate, but not the end of the world.

I ordered several 2mm solid carbide flat-bottom end mills, which are slightly smaller than the tap drill size of a 4-40 thread. I've had very good luck drilling out broken taps with carbide end mills. Crossing my fingers it goes smoothly here, as I've probably got 5 hours into each of the heads so far.

View attachment 379963 View attachment 379964