What's wrong with the cardboard box? Its functional & low environmental impact LOL

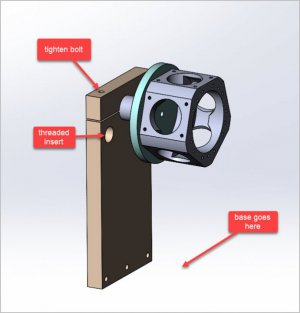

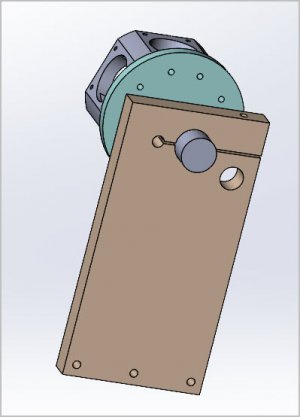

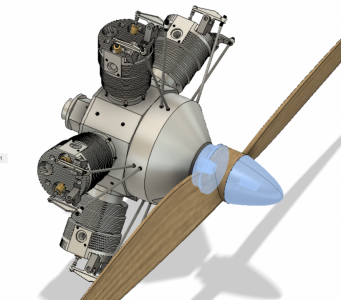

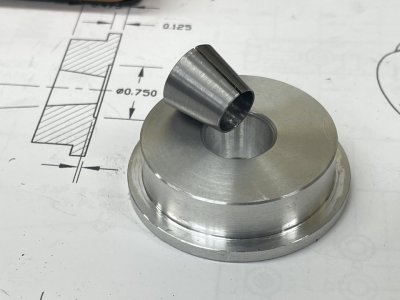

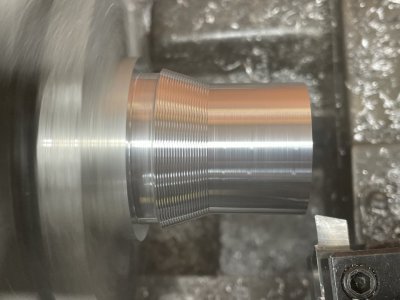

My pic is still in camera but I made this rotisserie contraption mostly to help with assembly. Hopefully makes sense. The idea is I can rotate the engine to any position, lock it in position & work on one cylinder at a time in upright mode for all the fiddly parts. At this point the rear manifold is off so the plate just mounts to my crankcase bolt pattern. Except for the 0.75" aluminum axle, its just MDF so wont hurt my feelings if it doesn't work out. I kind of have 2 competing ideas for a motor mount otherwise I would have designed it to double as a display stand with manifold on, but cross that bridge when I get there.

My pic is still in camera but I made this rotisserie contraption mostly to help with assembly. Hopefully makes sense. The idea is I can rotate the engine to any position, lock it in position & work on one cylinder at a time in upright mode for all the fiddly parts. At this point the rear manifold is off so the plate just mounts to my crankcase bolt pattern. Except for the 0.75" aluminum axle, its just MDF so wont hurt my feelings if it doesn't work out. I kind of have 2 competing ideas for a motor mount otherwise I would have designed it to double as a display stand with manifold on, but cross that bridge when I get there.