- Joined

- Feb 14, 2020

- Messages

- 166

Hello everyone...

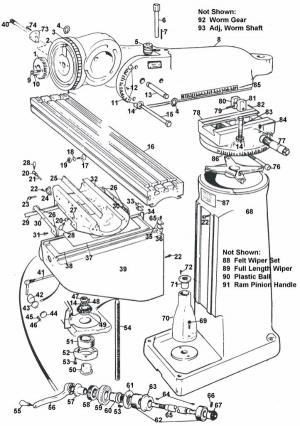

I'm doing a Bridgeport restoration project and ran in to an issue. When I went to pull the gear shaft clutch insert it broke away. Now the portion that slips under the dial holder is seized. I've tried some light prying between the dial holder and bearing retainer ring, I've tried supporting it under the bearing retainer ring and tapping it down on the top of the shaft, I've hit it lightly with the air hammer and a pointed chisel in the shaft's center hole, and I've oiled it down good and hit it with heat. It won't move.

I'm assuming from videos and pictures I've seen, these two parts (gear shaft clutch insert and dial holder) should pull straight off as they're keyed to the shaft.

What am I missing here? I'm beginning to think the only way to reclaim my elevator shaft is to cut off the clutch insert and dial holder with a cutoff wheel.

I'm doing a Bridgeport restoration project and ran in to an issue. When I went to pull the gear shaft clutch insert it broke away. Now the portion that slips under the dial holder is seized. I've tried some light prying between the dial holder and bearing retainer ring, I've tried supporting it under the bearing retainer ring and tapping it down on the top of the shaft, I've hit it lightly with the air hammer and a pointed chisel in the shaft's center hole, and I've oiled it down good and hit it with heat. It won't move.

I'm assuming from videos and pictures I've seen, these two parts (gear shaft clutch insert and dial holder) should pull straight off as they're keyed to the shaft.

What am I missing here? I'm beginning to think the only way to reclaim my elevator shaft is to cut off the clutch insert and dial holder with a cutoff wheel.