- Joined

- Apr 12, 2011

- Messages

- 3,461

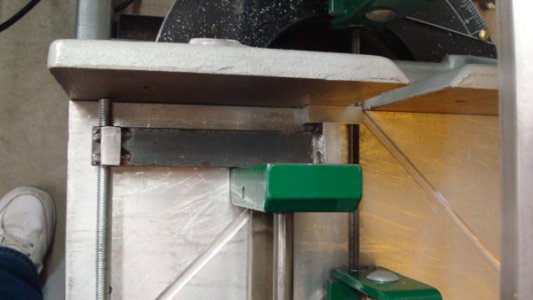

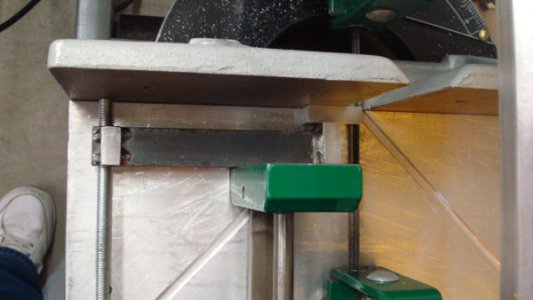

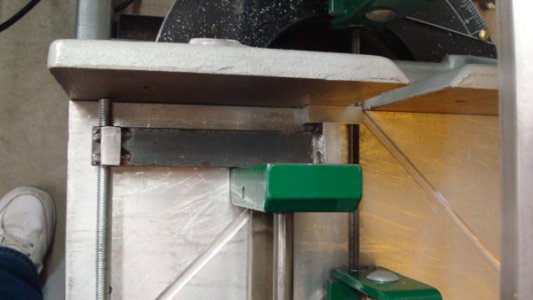

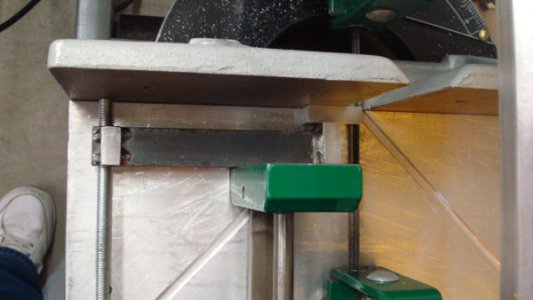

My Ellis band saw has a quick acting vise for holding the stock in place while cutting. The vise can not be located real close to the blade and can cause a clamping issue when trying to cut really short pieces even shorter. So, here is my solution. I made an adjustable clamp. Seems to work pretty well.

And yeah I know, it still needs some paint.

And yeah I know, it still needs some paint.