- Joined

- Dec 20, 2021

- Messages

- 866

I have 'snap action style' switches on two mills for use as homing switches. Not this exact brand, but the snap acting types are all very similar. The first set was supplied by the manufacturer, the second set I chose for a build because they work so well. Basically, I'm seeing repeatability to a tenths or so. I could get exact part numbers from the switches later, if you are interested.... First thing is to come up with a proximity switch that can be the emergency stop. This switch needs to be very repeatable to within a few thousandths. I think there are some that will do this, but I don't know if they are small enough for our sized lathes. The ones I have seen are fairly long.

There are different plunger options. If they were mounted with the plunger perpendicular to the travel, and you used a ramp or cam to activate it (so over travel wouldn't damage the switch) I think they'd be just fine for this application.

Reading this thread makes me want to get started the ELS for the lathe here too!

Dan

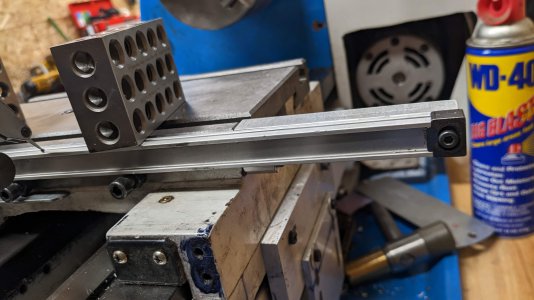

Will be adding some better DRO's to my lathe. They have been ordered, but haven't quite left the mother country. Soon I hope. Then the adventure of fitting them onto the platform begins. I *think* they will fit. I do love having the DRO's integrated with the controller.

Will be adding some better DRO's to my lathe. They have been ordered, but haven't quite left the mother country. Soon I hope. Then the adventure of fitting them onto the platform begins. I *think* they will fit. I do love having the DRO's integrated with the controller.