Hi Steve,

Little update on the follower-rest: I made some dimensional adjustments to the 3D-model, which I’m guessing is due to building your own version of the Emco C8.

I made the follower-rest from a slab of mild steel that was lying around. I started out with a basic outline and used an angle grinder to cut it out. Then milled the surfaces to dimensions. I wasn't too critical here, since the only real important dimension of this part is where the 'fingers' of the follower rest meet, the centerline between chuck and centre.

First, I thought I’d do a fancy type of follower rest like the commercial produce with the arched body and mesh fingers, but I don’t have the CNC capability to neatly mill those radii. Then I settled for a straight type version with the mesh fingers, but decided to lose those details (mesh, etc), since I'll probably need this tool only a handful of times.

This project is relatively simply to the work you've been doing on your own lathe and the steady and follower rest you've made (which include the mesh parts). However, I wanted to share this with you and the rest because what I like about this design is that it is about as no-nonsense as it gets for a follower rest. Perhaps in this way the design options for making a follower-rest presented in this thread can help others in making one of their own based on prospected machining needs.

Thanks again for sharing your 3D-models and good luck with your project!

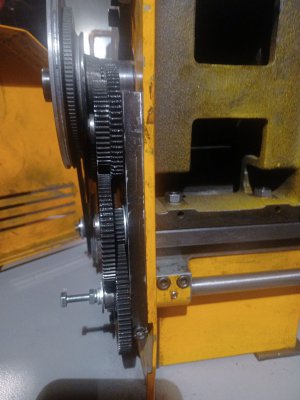

View attachment 385050View attachment 385051View attachment 385052View attachment 385053View attachment 385054View attachment 385055View attachment 385056View attachment 385057View attachment 385058 Here’s some pics.