- Joined

- May 8, 2018

- Messages

- 336

You got a very good deal, perhaps 1/2 of what I would see in my area.

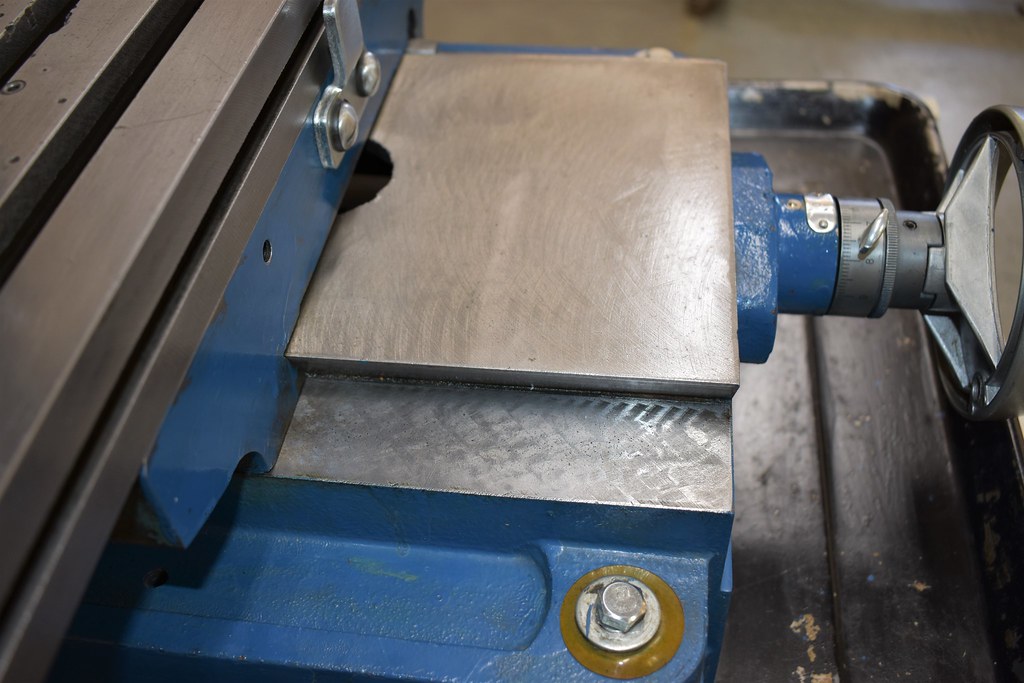

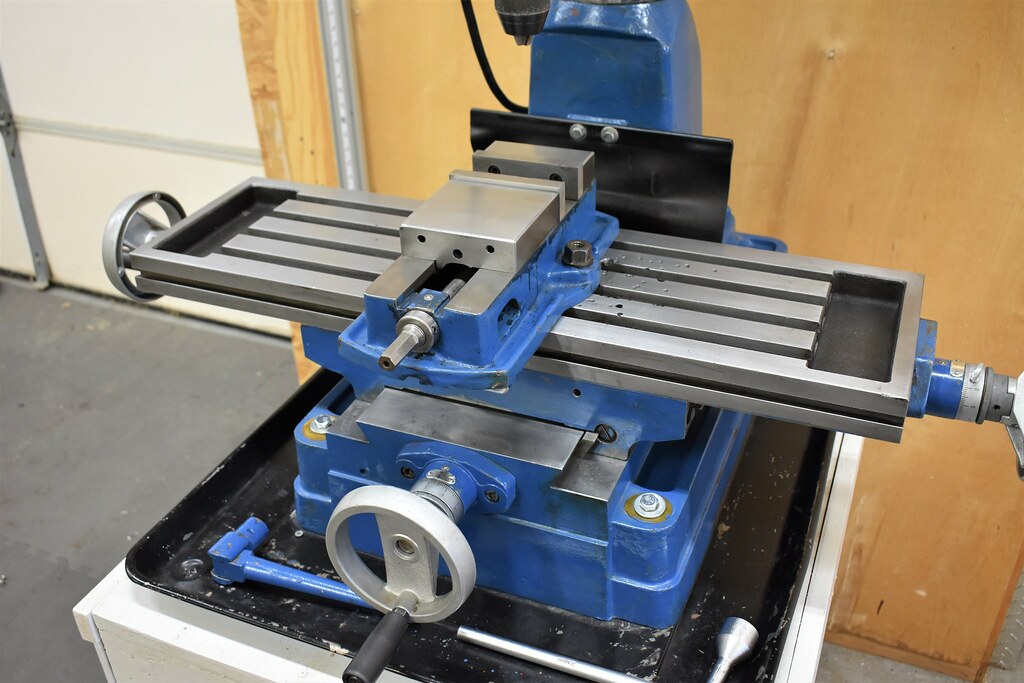

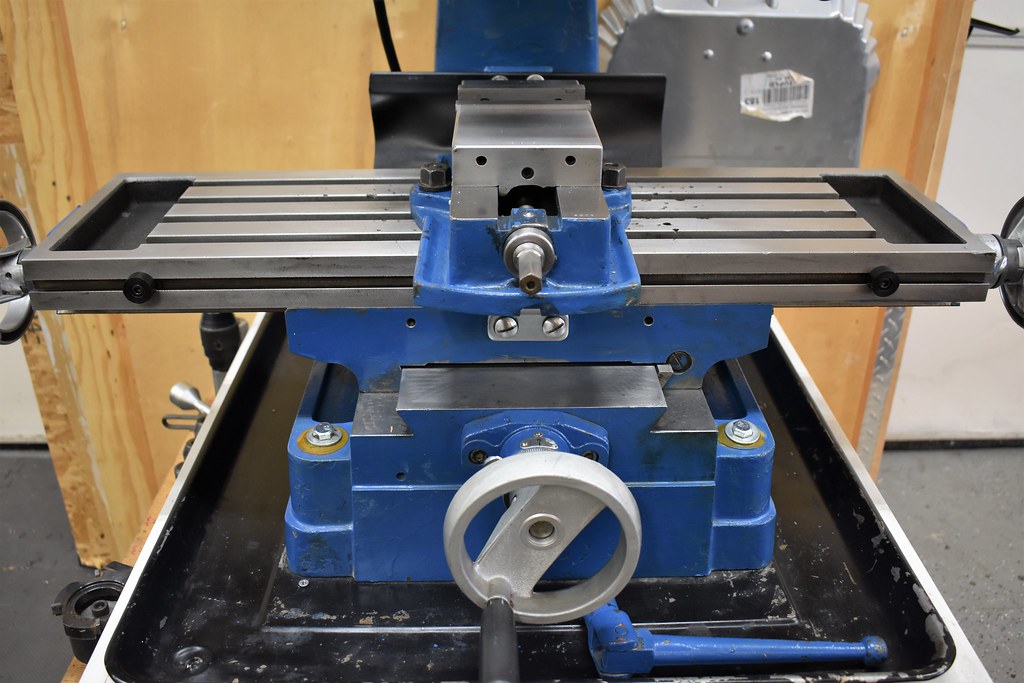

The picture of the mill in his shop with the piece of wood explains how he got so many hiccups in the table due to not having sacrificial boards behind the pieces being drilled.

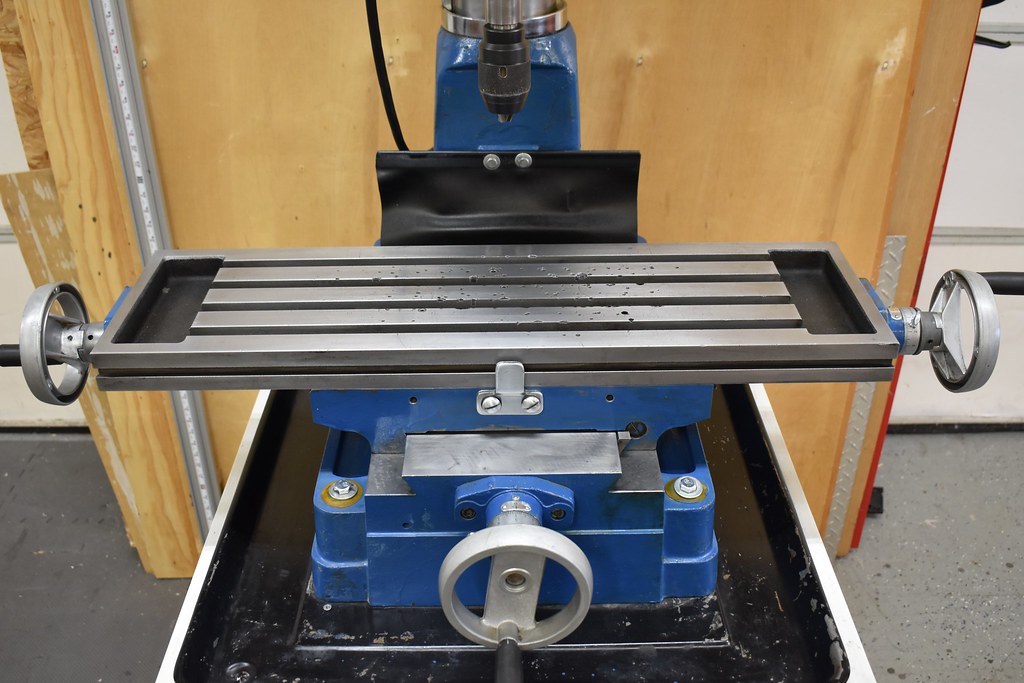

As others have mentioned, stoning to remove edges and burrs is all you need. The vise will cover the hiccups in the middle. On my milling machine I use UHMW covers on either side. If you did something similar you would rarely see the hiccups.

I love these covers. They reflect light which is desirable for the present lighting situation. They also protect the table from tooling or work hitting the table when "Murphy" pays a visit. Also much easier to clean up chips and debris with the flat surfaces.

I am not using flooded coolant. If I did I could just slide the covers to provide more space for the coolant to drain off the vise into the slots in the table.

View attachment 269231

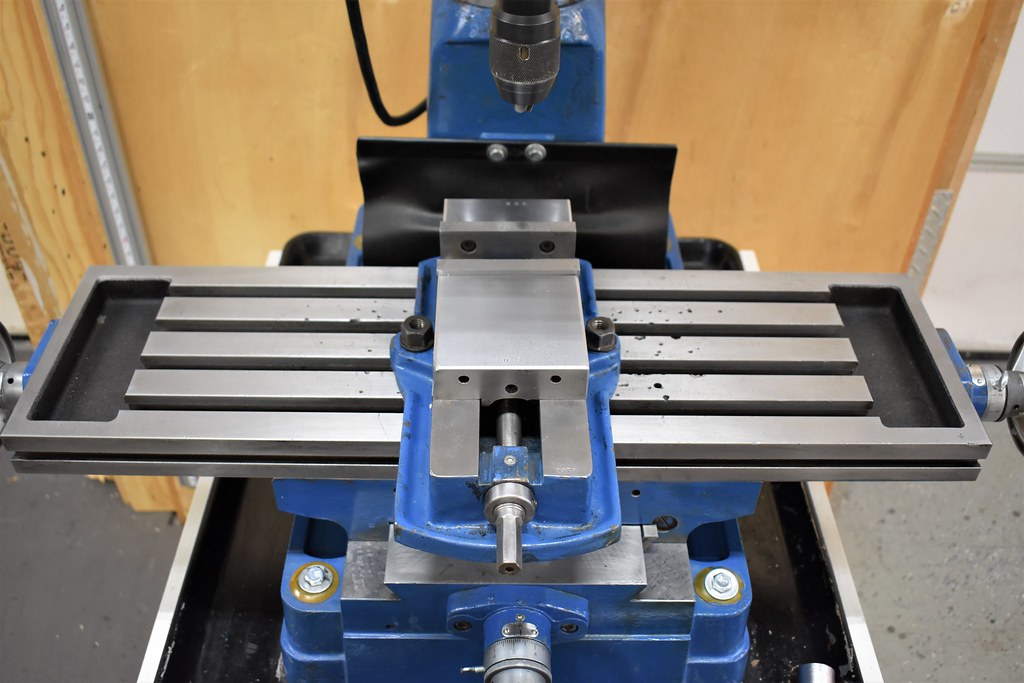

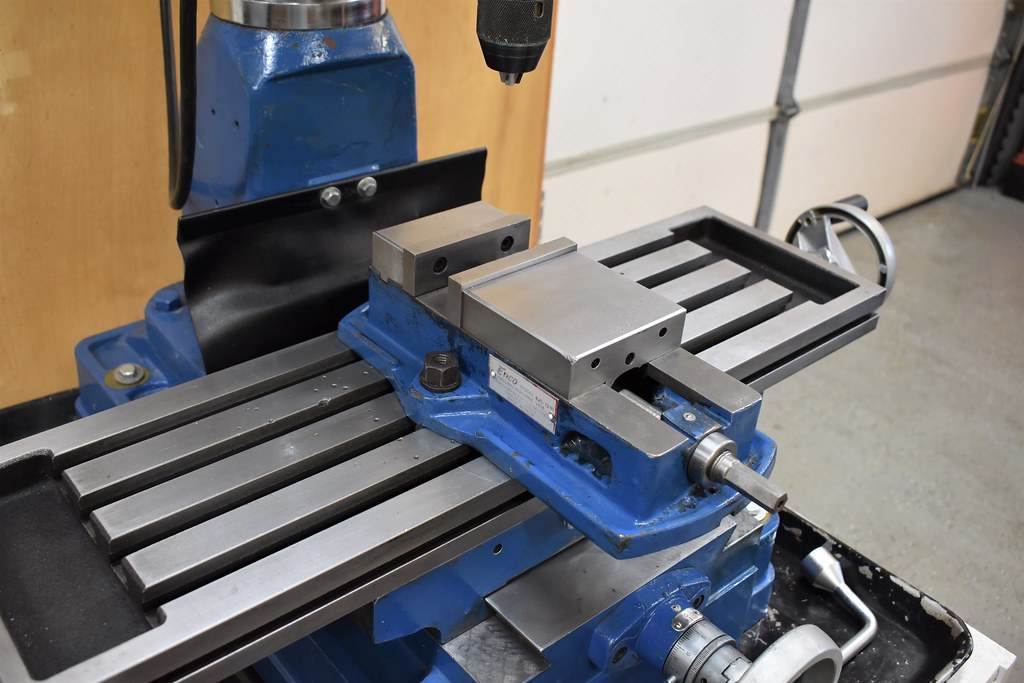

I would consider mounting the vise without the rotary base unless you need the swivel for a project. The mill does not have a lot of Z axis capacity so the rotary base will consume some much needed travel capacity.

I like that a lot. As I am drooling on the picture I'm calculating in my head how long it would take me just to make my vise look like that. lol...

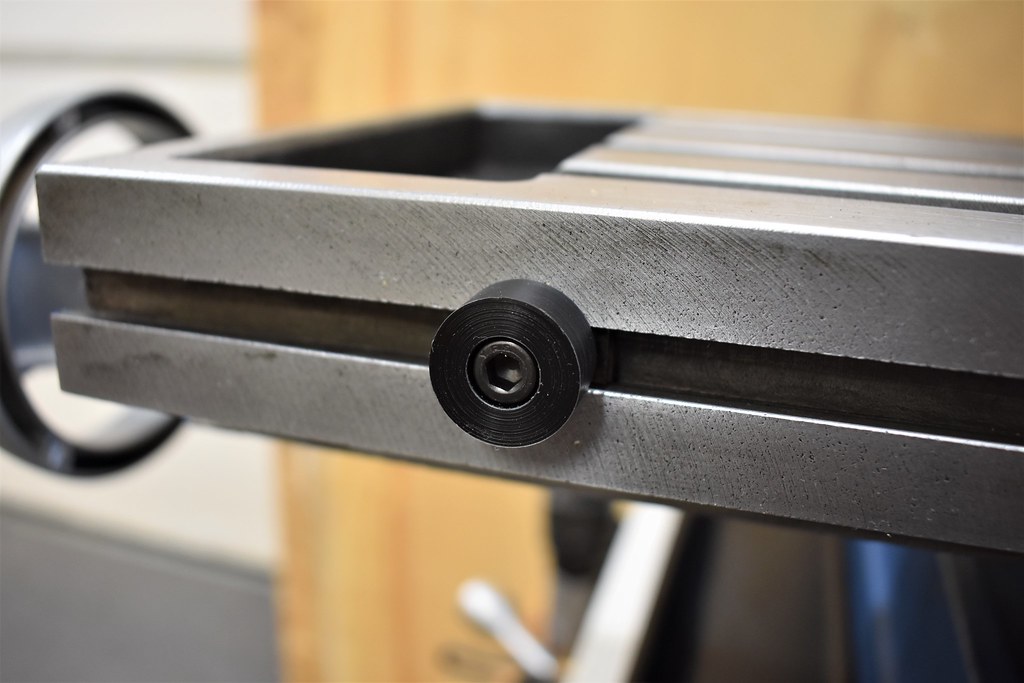

These are 1/4" UMHW sheets? I see the screws so I'm assuming there are perhaps more UMHW pieces on the back to locate the sheets on the table?

Last edited: