- Joined

- Jan 11, 2020

- Messages

- 5

Hello all fist post, hopefully many more to come.

I have been sitting on a used (broken) Enco 110-0820, with base, that my friend couldn't afford to fix at the time and I picked it up for free. I have all the parts that I know are broken (I bought them from Enco almost 7 years ago). After moving 1/2 way across the US. I now have a little time and a tiny amount of money to try and repair this thing.

I have found the manual enco-110-0820.pdf (this link is just one of the same document I have found everywhere)

Here are my questions along with pictures.

1, What bolts are used to mount the lathe to the base?

2, I got grease for the ways, and the lubrication guide in the manual shows several places to Grease/Oil, but what lubricants are these? I've read that you shouldn't use Automotive Oil.

3, I have used steel wool and automotive oil to remove most of the rust. Is there something better to use to keep it from rusting again? I was planning on using paste wax like I use on my woodworking machines.

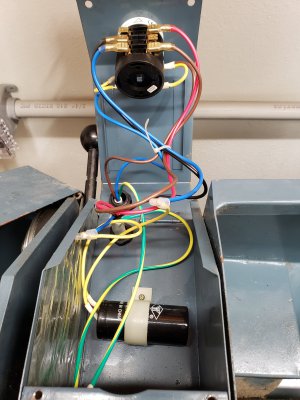

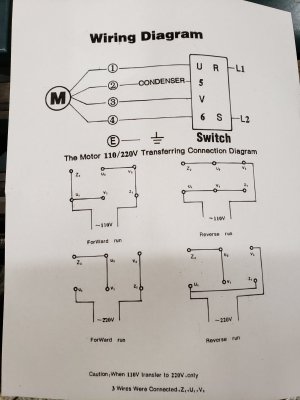

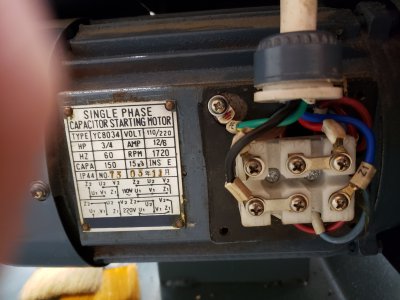

4. Does anyone have a better description of how to correctly wire this thing? I would like the ground to be connected if possible.

Once I get it running. I plan on learning to cut threads (I hear the ladies love to hear this from guys). I won't ask questions about this till I get the thing working.

I have been sitting on a used (broken) Enco 110-0820, with base, that my friend couldn't afford to fix at the time and I picked it up for free. I have all the parts that I know are broken (I bought them from Enco almost 7 years ago). After moving 1/2 way across the US. I now have a little time and a tiny amount of money to try and repair this thing.

I have found the manual enco-110-0820.pdf (this link is just one of the same document I have found everywhere)

Here are my questions along with pictures.

1, What bolts are used to mount the lathe to the base?

2, I got grease for the ways, and the lubrication guide in the manual shows several places to Grease/Oil, but what lubricants are these? I've read that you shouldn't use Automotive Oil.

3, I have used steel wool and automotive oil to remove most of the rust. Is there something better to use to keep it from rusting again? I was planning on using paste wax like I use on my woodworking machines.

4. Does anyone have a better description of how to correctly wire this thing? I would like the ground to be connected if possible.

Once I get it running. I plan on learning to cut threads (I hear the ladies love to hear this from guys). I won't ask questions about this till I get the thing working.