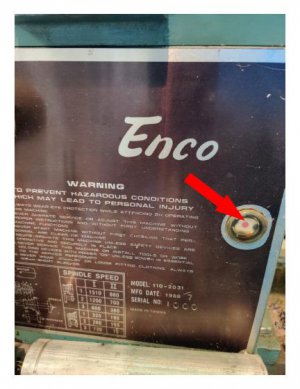

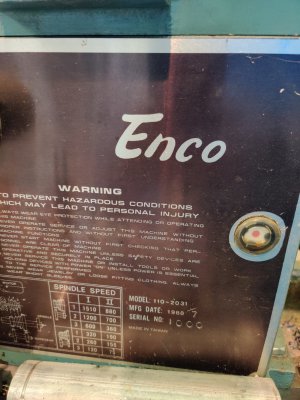

I have just acquired a lathe that claims to be an Enco 110-2031 manufactured in 1988 (/7), serial number 1000 (if you can believe it). It was apparently manufactured in Taiwan.

I believe this lathe was setup for 110v operation, despite the large "220v" sticker on the outside of the wiring box, because it has a 5-20R cord attached (normal 110v cord with the sideways blade). While I had originally believed it was setup for 220v, this is ok for now, because I have these outlets available to me, while 220v is not yet installed.

I do not have a manual for this machine (would love a PDF copy if anyone had one!), so I am not confident of the wiring diagram. Also, there is a switch missing that I need to wire up (bottom of the machine, just to the right of the threading gearbox):

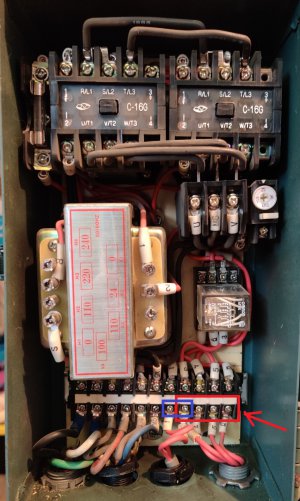

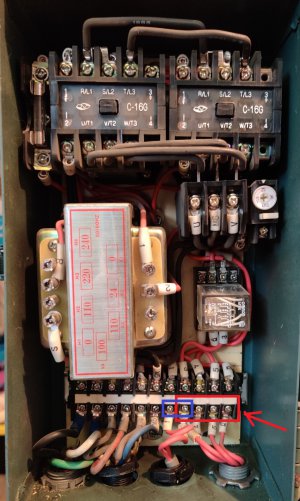

These wires originate in the wiring box, marked here in red (the two marked in blue go to the e-stop switch):

Can anyone help me out with what switch I'm missing and how I'd wire it up? Also, it'd be fantastic if anyone had a wiring diagram or could verify that my wiring looks correct. Thanks!

I believe this lathe was setup for 110v operation, despite the large "220v" sticker on the outside of the wiring box, because it has a 5-20R cord attached (normal 110v cord with the sideways blade). While I had originally believed it was setup for 220v, this is ok for now, because I have these outlets available to me, while 220v is not yet installed.

I do not have a manual for this machine (would love a PDF copy if anyone had one!), so I am not confident of the wiring diagram. Also, there is a switch missing that I need to wire up (bottom of the machine, just to the right of the threading gearbox):

These wires originate in the wiring box, marked here in red (the two marked in blue go to the e-stop switch):

Can anyone help me out with what switch I'm missing and how I'd wire it up? Also, it'd be fantastic if anyone had a wiring diagram or could verify that my wiring looks correct. Thanks!