- Joined

- Mar 26, 2018

- Messages

- 2,724

Chapter 4: Man this thing is dirty

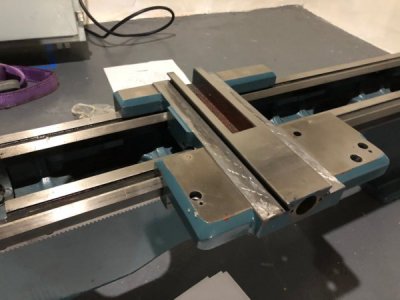

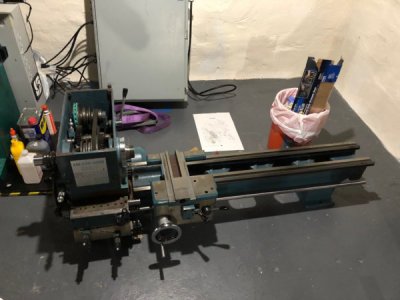

So now that the lathe was in the garage the fun could begin. Each night after work and cooking dinner, I would venture out with a headlamp and plastic tub to strip parts from the machine and carry them down the basement. I could only stand the cold for so long, so half of the time I would be cleaning parts in the basement.

(The big 2x4 was used to loosen the chuck)

Each part was meticulously cleaned and coated in a thin coat of oil to prevent rust. Each part was labeled with a number matching the grizzly parts list. Fortunately I only have 2 bolts which I failed to label, but they are big and I have confidence that they will identify themselves as I reassemble the lathe.

For reference, the basement was pretty and clean before this whole thing started (and before the mill and the rest of my tools arrived).

I don't have too many pictures of the actual cleaning, but you get the idea. I went through 8 rolls of paper towels, 2 bottles of rubbing alcohol, a bottle of citrus de-greaser, a jug of dawn dish soap, and a quart of engine oil. I found the rubbing alcohol to be the best for cleaning the sludge from the parts as it readily mixes with grease and oil and dries quickly (it does eat through the paint on the basement floor though). The citrus de-greaser worked well for some of the parts like the leadscrew which could be soaked overnight in a PVC pipe filled with the stuff, but wasn't great for general cleaning. I have read elsewhere that the citrus stuff will bleach the paint and etch metals, but I found it to be very mild and did not find any issues with its use.

The collection of parts quickly grew and It started to consume the basement floor (I don't own workbenches yet).

Some of the larger and dirtier items were cleaned in the garage whenever it was nice enough to do so.

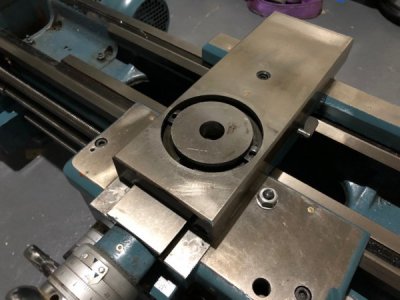

The apron was partially disassembled for cleaning and flushed with lightweight oil. When I dumped this oil into my oil tub, several roll pins fell out. I carefully checked all the shafts in the gearbox and they all had their pins, so these must have fallen in during factory assembly and sat there until now. Free pins! (I needed one of these later after destroying a different one). It's much cleaner and shiner now!

The quick change gearbox was fairly dirt free, but did not spin smoothly at all. I could barely spin the input shaft with all my strength. As I began cleaning it with a toothbrush, an incredible amount of grit and dirt started sloughing off. After 4 hours of cleaning and flushing with light oil, the gearbox spins smooth as silk and the input shaft can be turned between two fingers. I did replace the bearing on the keyed shaft which the arms are mounted to as they were blown (Open bearings in an open gearbox? Who thought that was a good idea?). I am impressed by the oiling system in this lathe, each bushing in the gearbox has a feed tube from an oil reservoir.

That's all for now. Stay tuned for Chapter 5: Hope the stairs can take it

So now that the lathe was in the garage the fun could begin. Each night after work and cooking dinner, I would venture out with a headlamp and plastic tub to strip parts from the machine and carry them down the basement. I could only stand the cold for so long, so half of the time I would be cleaning parts in the basement.

(The big 2x4 was used to loosen the chuck)

Each part was meticulously cleaned and coated in a thin coat of oil to prevent rust. Each part was labeled with a number matching the grizzly parts list. Fortunately I only have 2 bolts which I failed to label, but they are big and I have confidence that they will identify themselves as I reassemble the lathe.

For reference, the basement was pretty and clean before this whole thing started (and before the mill and the rest of my tools arrived).

I don't have too many pictures of the actual cleaning, but you get the idea. I went through 8 rolls of paper towels, 2 bottles of rubbing alcohol, a bottle of citrus de-greaser, a jug of dawn dish soap, and a quart of engine oil. I found the rubbing alcohol to be the best for cleaning the sludge from the parts as it readily mixes with grease and oil and dries quickly (it does eat through the paint on the basement floor though). The citrus de-greaser worked well for some of the parts like the leadscrew which could be soaked overnight in a PVC pipe filled with the stuff, but wasn't great for general cleaning. I have read elsewhere that the citrus stuff will bleach the paint and etch metals, but I found it to be very mild and did not find any issues with its use.

The collection of parts quickly grew and It started to consume the basement floor (I don't own workbenches yet).

Some of the larger and dirtier items were cleaned in the garage whenever it was nice enough to do so.

The apron was partially disassembled for cleaning and flushed with lightweight oil. When I dumped this oil into my oil tub, several roll pins fell out. I carefully checked all the shafts in the gearbox and they all had their pins, so these must have fallen in during factory assembly and sat there until now. Free pins! (I needed one of these later after destroying a different one). It's much cleaner and shiner now!

The quick change gearbox was fairly dirt free, but did not spin smoothly at all. I could barely spin the input shaft with all my strength. As I began cleaning it with a toothbrush, an incredible amount of grit and dirt started sloughing off. After 4 hours of cleaning and flushing with light oil, the gearbox spins smooth as silk and the input shaft can be turned between two fingers. I did replace the bearing on the keyed shaft which the arms are mounted to as they were blown (Open bearings in an open gearbox? Who thought that was a good idea?). I am impressed by the oiling system in this lathe, each bushing in the gearbox has a feed tube from an oil reservoir.

That's all for now. Stay tuned for Chapter 5: Hope the stairs can take it